What is a Watts Pressure Relief Valve and How Does It Work?

The Watts pressure relief valve is a crucial safety device in various industries, particularly in HVAC, plumbing, and chemical processing. According to recent industry reports, nearly 70% of all equipment failures stem from pressure-related issues. This alarming statistic underscores the need for reliable pressure management solutions.

Pressure relief valves are designed to protect systems from exceeding their pressure limits. The Watts pressure relief valve effectively prevents catastrophic failures that can result from excessive pressure build-up. This valve is engineered for performance and durability, serving critical roles in residential and commercial applications.

However, not all installations are perfect. Some users report challenges in maintaining optimal functionality over time. A lack of regular maintenance can lead to reduced effectiveness. It is essential for operators to regularly inspect and test these valves to ensure they perform as intended. As the industry evolves, so too must our commitment to safeguarding systems through effective pressure relief mechanisms like the Watts pressure relief valve.

What is a Watts Pressure Relief Valve?

A Watts Pressure Relief Valve is a crucial safety device used in various systems. Its primary function is to automatically release excess pressure. This prevents potential damage to pipes and machinery. These valves respond to pressure changes in real-time. When pressure reaches a preset limit, the valve opens. This action allows fluid to escape, reducing the pressure.

Understanding how these valves work is essential. They often include a spring mechanism that holds the valve closed. When pressure builds up, the force exceeds the spring tension. This causes the valve to lift, allowing fluid to pass. However, if the spring is worn or malfunctioning, it might not function properly. Regular maintenance is necessary to ensure optimal performance.

Pressure relief valves are integral to safety in industrial settings. They protect equipment from catastrophic failure. The design of these valves can vary. Some may not respond as quickly as others, leading to potential risks. It’s crucial to select the right valve for your system. Ultimately, awareness and diligence are key in managing pressure effectively.

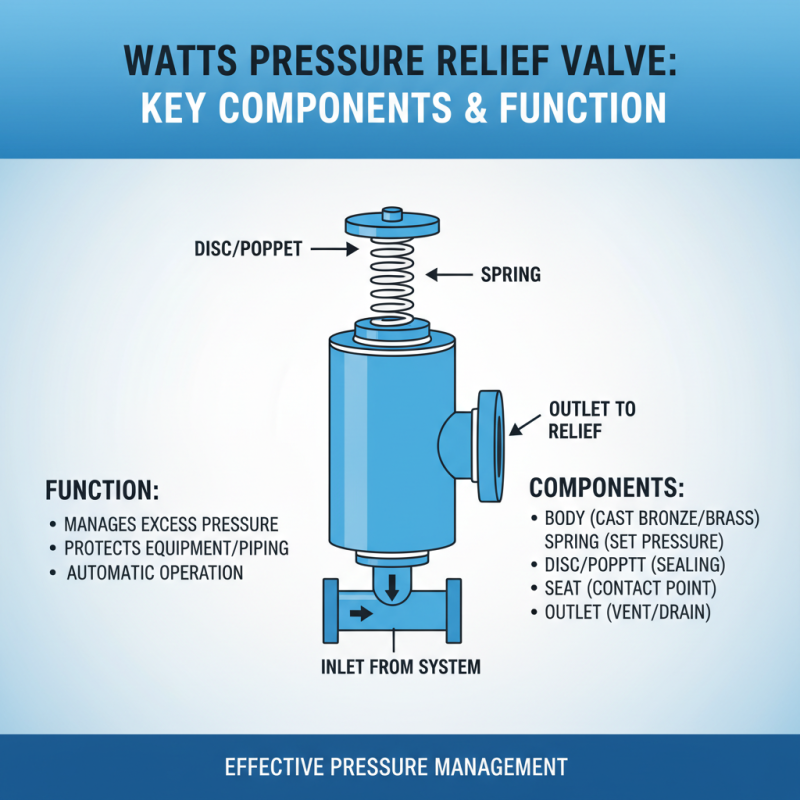

Key Components of a Watts Pressure Relief Valve

A Watts pressure relief valve plays a crucial role in various systems. It helps manage excess pressure effectively. Understanding its key components can shed light on its function.

The valve body is the main part. It houses other essential components. Spring-loaded mechanisms provide pressure control. When pressure rises too high, the spring compresses. This action opens the valve, allowing fluid to escape. It’s a simple yet effective design.

Another important component is the disk. It sits atop the valve seat. When pressure exceeds the set point, the disk lifts. This release helps to prevent system damage. A good relief valve must balance sensitivity and performance. Too sensitive, and it may open too often. Not sensitive enough, and it can fail under pressure.

These elements are vital for safety. However, if they malfunction, consequences could be severe. Regular maintenance is essential for reliable operation. Following best practices can help enhance performance over time.

How Does a Watts Pressure Relief Valve Function?

A Watts pressure relief valve functions to maintain safe pressure levels in various systems. It is designed to automatically release excess pressure when it surpasses a specific limit. This mechanism helps prevent equipment damage and ensures the safety of surrounding areas.

When pressure builds up, the valve opens, allowing fluid to escape. This action reduces the pressure in the system. Once the pressure drops to a safe level, the valve closes again. This cycle helps maintain balance and protects the integrity of the system. However, improper maintenance can lead to valve failure. Regular checks are essential for continued operation.

Tip: Always monitor the system's pressure readings. Make it a habit to inspect the valve regularly. A simple oversight could lead to costly damages. Additionally, remember that environmental factors can affect valve performance. Understanding these nuances is crucial for effective operation.

Pressure Relief Valve Flow Rates

This bar chart illustrates the flow rates of different sizes of pressure relief valves in Gallons Per Minute (GPM). As valve size increases, the flow rate capacity also increases, demonstrating the relationship between valve size and its performance in pressure relief applications.

Common Applications of Watts Pressure Relief Valves

Pressure relief valves play a vital role in various industries. They ensure systems operate safely under varying pressure conditions. These valves protect equipment from excessive pressure. They help prevent dangerous failures, bursting pipes, and leaks.

Common applications of pressure relief valves include water systems and gas pipelines. In water systems, they prevent overpressure from damaging pipes. In gas pipelines, these valves manage pressure fluctuations due to temperature changes. This helps maintain safe operational limits.

Pressure relief valves are also crucial in heating systems. They prevent overheating by releasing excess steam pressure. However, maintaining these valves is essential. Neglect could lead to malfunctions or safety hazards. Thus, regular checks are necessary to ensure reliability. It's important for operators to understand their function and upkeep.

What is a Watts Pressure Relief Valve and How Does It Work? - Common Applications of Watts Pressure Relief Valves

| Feature | Description | Common Applications |

|---|---|---|

| Function | Automatically releases excess pressure to protect system components | Industrial fluid systems, boilers, hot water tanks |

| Type of Valve | Spring-loaded relief valve | Water supply systems, chemical processing plants |

| Pressure Rating | Varies based on application; typically between 15 psi to 300 psi | Food processing, oil and gas industries |

| Benefits | Helps prevent overpressure situations, enhances safety | Power generation, HVAC systems |

| Material | Typically made of brass, stainless steel, or plastic | Water treatment facilities, pharmaceutical manufacturing |

Maintenance and Troubleshooting Tips for Watts Pressure Relief Valves

Maintaining a pressure relief valve is crucial for its efficiency. Regular inspection of the valve’s physical condition is important. Look for signs of wear, corrosion, or leaks. A simple visual check can often reveal potential problems. If the valve is failing, it might not open or close properly. This can compromise safety. Consider periodic testing to ensure functionality.

Troubleshooting issues can sometimes be a challenge. Ensure that the valve is properly adjusted to its set pressure. If it opens too early or doesn’t open at all, it may need recalibration. Clean the valve to remove any debris that might impede its operation. Remember, proper lubrication can also enhance performance. Be cautious though; applying too much lubricant can cause buildup.

Reflect on the overall system conditions as well. High levels of vibration or temperature fluctuations can adversely affect valve function. Keep an eye on the upstream and downstream components. A weak point in the system can lead to failures. Don’t overlook these factors; they are vital for long-term reliability. Regular maintenance and close monitoring can prevent costly breakdowns.

Related Posts

-

Top 2 Pressure Relief Valve Types You Should Know?

-

Why is a Pressure Relief Valve Essential for Safety and Performance?

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

2026 Top High Pressure Relief Valve Solutions for Industrial Applications