Understanding Vacuum Relief Valves for 2025 Top Applications and Benefits

In the rapidly evolving landscape of industrial processes, the role of the vacuum relief valve has become increasingly critical. A vacuum relief valve is designed to protect vessels from subatmospheric pressures that can lead to structural damage or failure. According to a report by MarketsandMarkets, the global vacuum relief valve market is anticipated to grow significantly, reaching an estimated value of USD 1.2 billion by 2025, driven by increasing demand across various sectors including chemical, food processing, and pharmaceuticals.

As industries strive for efficiency and safety, understanding the applications and benefits of vacuum relief valves is paramount. These valves provide essential pressure regulation, safeguarding against the risks associated with vacuum conditions. A recent study in the Journal of Pressure Vessel Technology revealed that improper vacuum management can lead to catastrophic failures, emphasizing the need for reliable vacuum relief solutions. Moreover, with the rising trend of automation and stringent regulatory standards, the integration of advanced vacuum relief valves has proven to enhance operational efficiency while ensuring compliance with safety protocols.

In summary, the importance of vacuum relief valves is underscored by their growing presence in key applications, highlighting their role in protecting industrial systems. As we delve deeper into the top applications and benefits of these crucial components for 2025, it becomes clear that investing in high-quality vacuum relief valves is not only a matter of compliance but also a strategic approach to risk mitigation and operational excellence.

Overview of Vacuum Relief Valves and Their Functionality

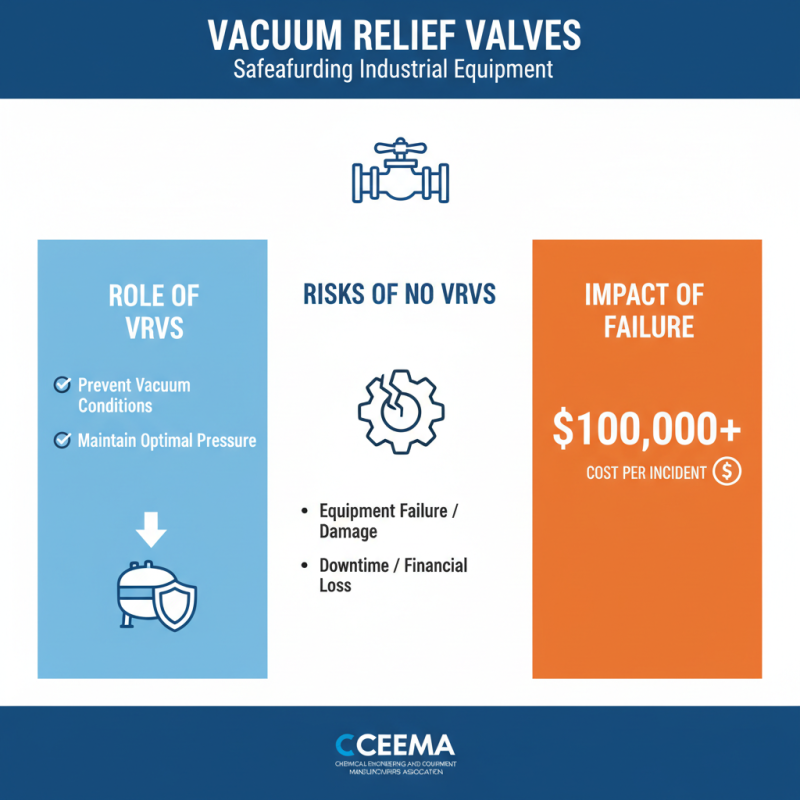

Vacuum relief valves (VRVs) are essential components in various industrial applications, serving a critical role in maintaining system integrity and preventing potential damage due to vacuum pressure. Operating at a predetermined pressure point, these valves open to allow atmospheric air into a vessel or piping system, thereby averting the risk of collapse or structural failure due to excessive vacuum conditions. According to a recent industry report by Grand View Research, the global market for vacuum relief valves is expected to grow significantly, driven by increased demand from sectors such as chemical processing, pharmaceuticals, and food and beverage, where maintaining precise pressure levels is crucial for safety and quality.

The functionality of vacuum relief valves is straightforward yet vital. They are designed with mechanisms that respond to changes in pressure within a system, ensuring that pressure drops do not exceed safe limits. Notably, they serve to protect equipment such as tanks and reactors, where the consequences of collapsing vessels can lead to costly downtime and safety hazards. The World Health Organization has emphasized the importance of effective pressure management in industrial processes, highlighting how vacuum relief valves enhance operational safety. Industry experts predict that with advancements in materials and design, VRVs will become even more efficient and reliable, further solidifying their importance in high-stakes applications, including those monitored by stringent safety standards.

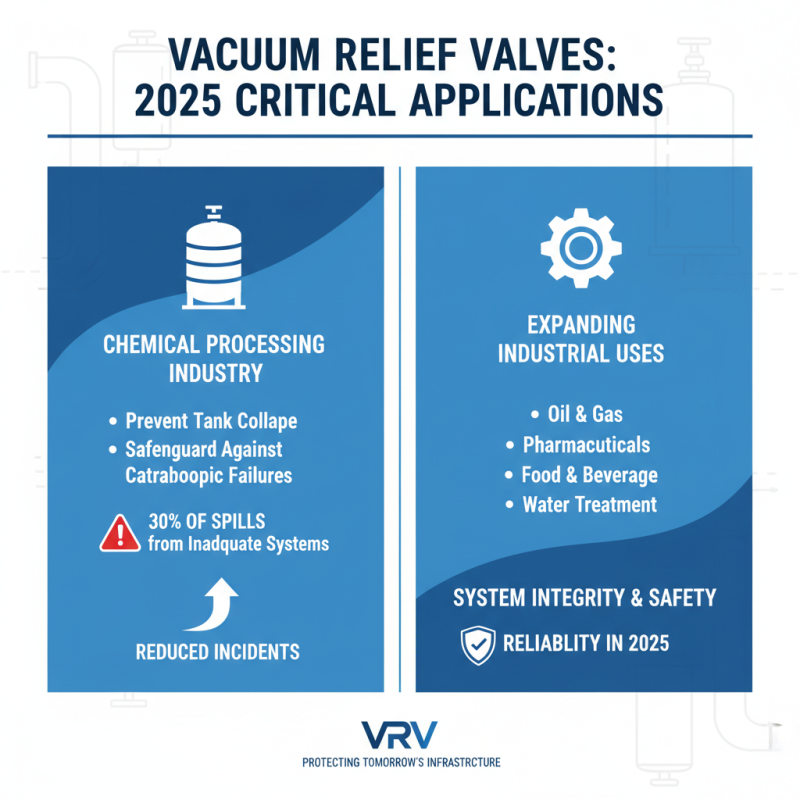

Key Applications of Vacuum Relief Valves in 2025

Vacuum relief valves play a crucial role in various industries, particularly in 2025, where their applications continue to expand. One of the primary applications is in the chemical processing industry, where maintaining the integrity of storage tanks is essential. According to a recent industry report, approximately 30% of incidents related to chemical spills can be traced back to inadequate vacuum relief systems. These valves help prevent the development of vacuum conditions that can lead to tank collapse, providing a necessary safeguard against catastrophic failures.

Another significant application of vacuum relief valves is within the food and beverage sector. As these industries increasingly focus on sustainability and efficiency, vacuum relief valves are essential in ensuring safe and efficient operations. Reports indicate that proper utilization of these valves can improve process reliability by up to 15%, thereby enhancing product quality and reducing waste. Additionally, within the pharmaceutical industry, maintaining appropriate pressure levels is vital for ensuring the efficacy of products. Research suggests that vacuum relief valves can help maintain a controlled environment, which is critical for the production of sensitive compounds and formulations.

Benefits of Using Vacuum Relief Valves in Industrial Settings

Vacuum relief valves (VRVs) play a crucial role in industrial applications by maintaining optimal pressure levels within equipment. These valves are essential for preventing vacuum conditions that can lead to equipment failure or damage. According to a recent report by the Chemical Engineering and Equipment Manufacturers Association, improper mitigation of vacuum pressure can result in significant financial losses, with industries potentially facing costs upwards of $100,000 per incident due to equipment repair and downtime.

In industrial settings, the benefits of using vacuum relief valves extend beyond mere equipment protection; they enhance operational efficiency and safety. Properly functioning VRVs allow for the smooth transfer of fluids and gases, minimizing the risk of cavitation and related issues in pipelines. A study from the Institute of Pressure Vessel Engineers indicates that the implementation of VRVs can reduce maintenance costs by up to 25%, as they effectively shield against the mechanical strain caused by fluctuating internal pressures. Furthermore, the safety benefits are paramount, as VRVs help to prevent hazardous failures that can endanger personnel and the surrounding environment, complying with stringent safety regulations enforced in various sectors.

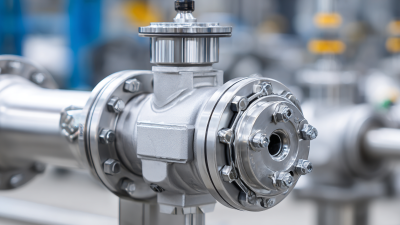

Factors Influencing the Performance of Vacuum Relief Valves

Vacuum relief valves play a crucial role in maintaining the integrity of storage and processing systems by preventing negative pressure buildup. Several factors can significantly influence their performance, ensuring optimal operation in various applications. One of the primary factors is the valve's sizing and selection, which must align with the specific requirements of the system. An appropriately sized valve can prevent excessive vacuum conditions, while a miscalibrated valve could lead to potential process failures or safety hazards.

Another critical aspect is the materials used in the fabrication of vacuum relief valves. The choice of materials can affect not only the valve's durability but also its resistance to corrosion and chemical wear. For industries handling aggressive substances, selecting the right materials ensures that the valve functions effectively over time, reducing maintenance costs and enhancing reliability.

Additionally, environmental conditions, such as temperature fluctuations and humidity, can also impact valve performance, necessitating careful consideration during installation and configuration to ensure long-lasting efficacy in various operational settings.

Future Trends in Vacuum Relief Valve Technology and Applications

As we look ahead to 2025, the evolution of vacuum relief valve technology is poised to play a critical role in various industries. One of the most significant trends is the integration of smart technology into these valves. With advancements in IoT, vacuum relief valves are now being designed with enhanced monitoring and control features. This capability allows for real-time data analysis, enabling more proactive maintenance and reducing downtime. Moreover, these smart valves can adapt automatically to changing process conditions, optimizing performance and safety.

Another emerging trend is the emphasis on sustainability and energy efficiency in the design of vacuum relief valves. Manufacturers are increasingly focused on creating products that not only meet safety standards but also minimize environmental impact. This includes the development of lightweight materials that reduce the overall carbon footprint during production and installation. In addition, designs that allow for better energy recovery during vacuum processes are gaining popularity, aligning with broader industry goals for reducing waste and promoting energy conservation. As these technology advancements unfold, vacuum relief valves are set to become more efficient and environmentally friendly, addressing the evolving needs of numerous applications.

Understanding Vacuum Relief Valves for 2025 Top Applications and Benefits

| Application | Industry | Benefits | Future Trends |

|---|---|---|---|

| Food and Beverage Processing | Food Industry | Prevents contamination, maintains product quality | Smart monitoring and remote control |

| Pharmaceutical Manufacturing | Pharmaceuticals | Ensures product integrity and safety | Integration with automation systems |

| Chemical Storage | Chemicals | Prevents tank collapse and chemical exposure | Improved materials resistant to corrosion |

| HVAC Systems | HVAC | Enhances system efficiency, prevents backflow | Energy-efficient designs and smart controls |

Related Posts

-

The Essential Role of Vacuum Relief Valves in Ensuring Safety and Efficiency in Industrial Systems

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

5 Best Pressure Vacuum Relief Valves for Optimal Safety and Performance in 2023

-

How to Choose a Low Pressure Relief Valve for Your System Needs

-

2025 Top 5 Safety Relief Valve Innovations You Should Know

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance