2026 Top Types of Temperature and Pressure Relief Valve Explained

Temperature and pressure relief valves are critical components in various industries. They ensure safety by preventing excessive pressure buildup and potential system failures. According to a recent report from the International Society for Fluid Dynamics, improper management of these valves can lead to catastrophic accidents. In fact, nearly 30% of industrial incidents stem from valve failures.

Expert David Thompson, a renowned safety engineer, stated, “The reliability of a temperature and pressure relief valve can make the difference between a controlled process and a dangerous situation.” His insights highlight the need for thorough understanding and regular maintenance of these valves. As systems evolve, so do the requirements for effective management.

Yet, the industry struggles with consistency. Many facilities overlook the importance of regular inspections. Some installations may even use outdated valve designs. This negligence can put personnel and equipment at risk. An informed approach is necessary to ensure that temperature and pressure relief valves perform optimally. Ultimately, prioritizing the right valve types can safeguard operations and enhance overall safety.

Types of Temperature and Pressure Relief Valves Overview

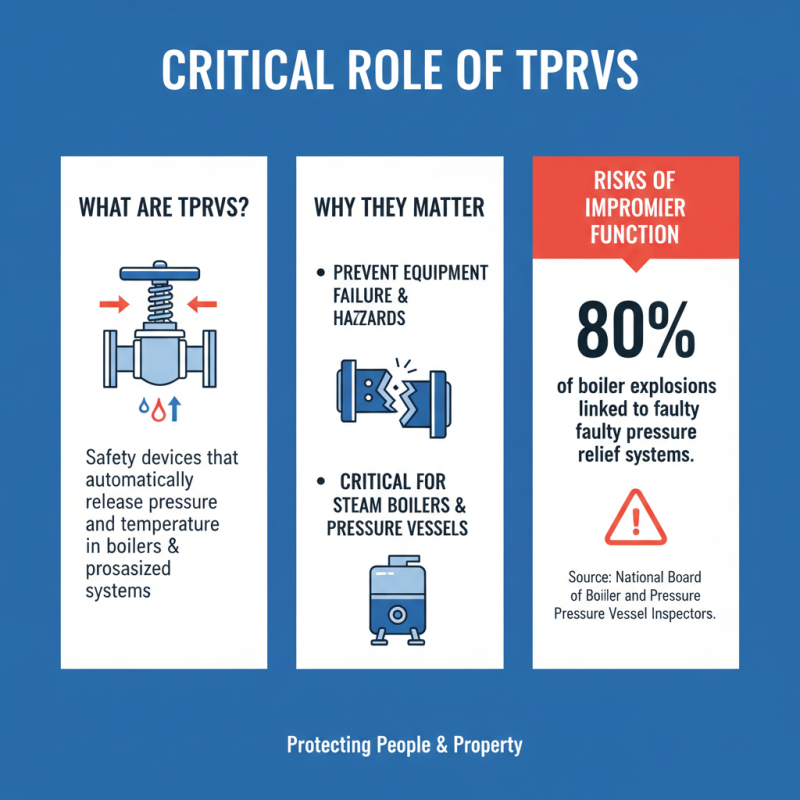

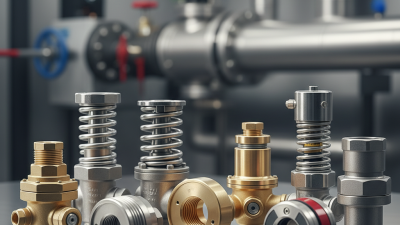

Temperature and pressure relief valves (TPRVs) are crucial for safety. They prevent equipment failure and explosions. Understanding their types can aid in proper selection. There are various TPRVs available, each serving unique applications.

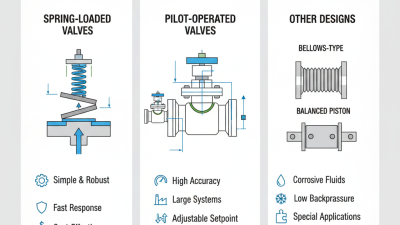

One common type is the spring-loaded valve. It operates using a mechanical spring. When pressure exceeds a certain level, the valve opens. This releases excess pressure. Another type is the weighted valve. It relies on gravity and weight to function. This type is often used in larger applications, like industrial settings. Each valve type has its strengths and weaknesses.

Choosing the right valve is not always straightforward. It's important to consider the specific conditions. Design specifications, temperature ranges, and pressure limits play a role. However, it’s easy to overlook these details. Neglecting them can lead to inefficiencies or safety hazards. It requires careful thought and understanding of the application.

2026 Top Types of Temperature and Pressure Relief Valves Explained

| Valve Type | Working Principle | Common Applications | Pressure Range (psi) | Temperature Range (°F) |

|---|---|---|---|---|

| Spring-Loaded Relief Valve | Uses a spring to hold a disc against the seat until pressure exceeds set point. | Boilers, Pressure Vessels, Water Heaters | 5-300 psi | -20 to 400 °F |

| Pilot-Operated Relief Valve | Relies on a pilot mechanism to control the main valve opening. | Chemical Processing, Oil & Gas | 30-2000 psi | -40 to 450 °F |

| Thermal Relief Valve | Opens to relieve pressure caused by thermal expansion in closed systems. | Pipelines, Tanks, Hydraulic Systems | 5-150 psi | -20 to 300 °F |

| Safety Valve | Automatically opens when system pressure exceeds maximum limits. | Steam Boilers, Pressure Vessels | 10-5000 psi | -50 to 650 °F |

Common Applications of Temperature and Pressure Relief Valves

Temperature and pressure relief valves (TPRVs) play a critical role in various industries. They are essential in preventing overpressure scenarios that could lead to equipment failure or hazardous situations. According to the National Board of Boiler and Pressure Vessel Inspectors, approximately 80% of boiler explosions are linked to improper pressure relief systems. This statistic highlights the significance of ensuring proper TPRV functioning in steam boilers and other pressurized systems.

Common applications include power generation, chemical processing, and water heating. In power plants, TPRVs safeguard steam systems, maintaining operational safety. In chemical facilities, they protect against dangerous reactions that may release excess pressure. Meanwhile, in residential water heaters, proper TPRVs prevent scalding or system failure. Despite their importance, many facilities overlook regular maintenance checks. In fact, the American Society of Mechanical Engineers suggests that regular inspections can reduce TPRV failures by up to 50%.

While many professionals recognize the necessity of TPRVs, there are still some challenges. Misalignment or improper sizing can undermine their effectiveness. Operators often assume that a TPRV is functioning properly without confirming it. This lack of diligence can lead to serious safety concerns. Companies should invest in training and regular inspections to ensure TPRVs operate efficiently. Awareness and education remain crucial in this essential safety domain.

How Temperature and Pressure Relief Valves Work

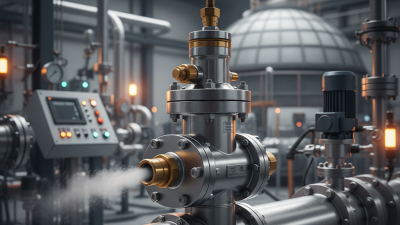

Temperature and pressure relief valves (TPRVs) play a critical role in maintaining safety in various industrial applications. These valves prevent the dangerous accumulation of pressure by automatically releasing excess steam or fluid. In many cases, they are essential in steam boilers and hot water tanks to avoid catastrophic failures. According to industry data, nearly 90% of boiler-related accidents can be linked to failures in TPRV functions.

Understanding how TPRVs operate is crucial. The valve works by sensing pressure changes within a system. When the pressure exceeds a preset limit, the valve opens automatically. This action can prevent explosions and equipment damage. In fact, studies indicate that effective TPRV systems can reduce incident risks by up to 75%. However, the effectiveness hinges on regular maintenance, as many TPRVs can become stuck or fail to operate if not regularly inspected.

Relying solely on their functionality can be risky. Some operators overlook the need for periodic testing. A valve that has not been checked may not respond properly in an emergency. Reports highlight that approximately 25% of TPRVs are not functioning correctly due to neglect. As a result, ensuring these valves are in prime condition should be a top priority for safety in any facility using pressurized systems.

Key Features and Specifications of Relief Valves

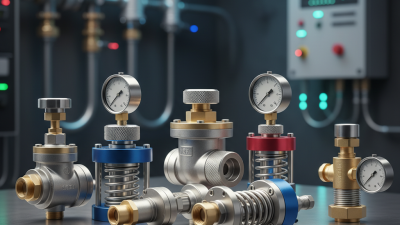

Temperature and pressure relief valves are crucial safety devices in various industries. According to the latest industry report, around 30% of equipment failures result from pressure issues. These valves need to meet specific standards. Their design often incorporates features like thermal relief to prevent overheating. The capacity is equally important. The valve must efficiently handle the maximum pressure expected during operation.

Key specifications focus on materials and response times. Commonly, brass and stainless steel are favored for their durability. The selected material often impacts the valve's longevity and reliability. A study has shown that valves with lower response times significantly reduce the risk of equipment damage. It’s essential for engineers to prioritize these specifications during installation and maintenance.

However, not all relief valves are foolproof. Some may fail to open under certain conditions. Regular testing is essential to ensure they perform as expected. Many organizations overlook this aspect, leading to costly repairs. Stakeholders must understand the critical role these valves play in maintaining system safety and efficiency.

2026 Top Types of Temperature and Pressure Relief Valve Explained

Maintenance and Safety Considerations for Relief Valves

Maintenance of temperature and pressure relief valves is crucial for safe operation. Regular inspection is essential to ensure these valves function correctly. Neglecting this can lead to unforeseen failures. According to industry reports, nearly 20% of valve failures occur due to lack of maintenance. It's vital to conduct periodic testing every six months.

Tips: Keep a maintenance log. Document each inspection and repair. This helps track performance and identify potential issues early.

Safety considerations cannot be overlooked. Operators must understand how to replace these valves properly. Misinstallation can lead to catastrophic failures. In fact, up to 40% of incidents are linked to improper valve handling. Proper training for staff is non-negotiable to prevent accidents.

Tips: Use visual aids during training. This enhances understanding and retention of safety protocols. Also, foster an environment where workers feel comfortable raising concerns about valve performance.

Related Posts

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

2026 Top High Pressure Relief Valve Solutions for Industrial Applications

-

2026 Top Types of Inline Pressure Relief Valves for Efficient Systems?

-

2026 Best Adjustable Pressure Relief Valve Reviews and Buying Guide?

-

2026 Top Air Pressure Relief Valve Types and Their Applications?

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance