2026 Top Air Pressure Relief Valve Types and Their Applications?

The air pressure relief valve industry is crucial for ensuring safety in various applications. According to a report from the Global Valve Network, the market for air pressure relief valves is expected to grow at a CAGR of 7.5% from 2023 to 2026. This growth highlights the increasing importance of these devices in preventing overpressure situations.

Expert in the field, Dr. Lisa Harrington, states, "Air pressure relief valves are integral for protecting equipment and personnel." This underscores the need for reliability in valve performance. However, many manufacturers continue to face challenges in maintaining consistent quality. Issues such as poor material selection or incorrect sizing often lead to valve failures.

Moreover, while many organizations adhere to industry standards, some still rely on outdated designs. These problems can result in safety risks and revenue loss. The air pressure relief valve landscape demands continuous improvement and innovation. As industries evolve, so too must the technologies that protect them. The 2026 landscape will require a keen focus on both performance and safety.

Overview of Air Pressure Relief Valves

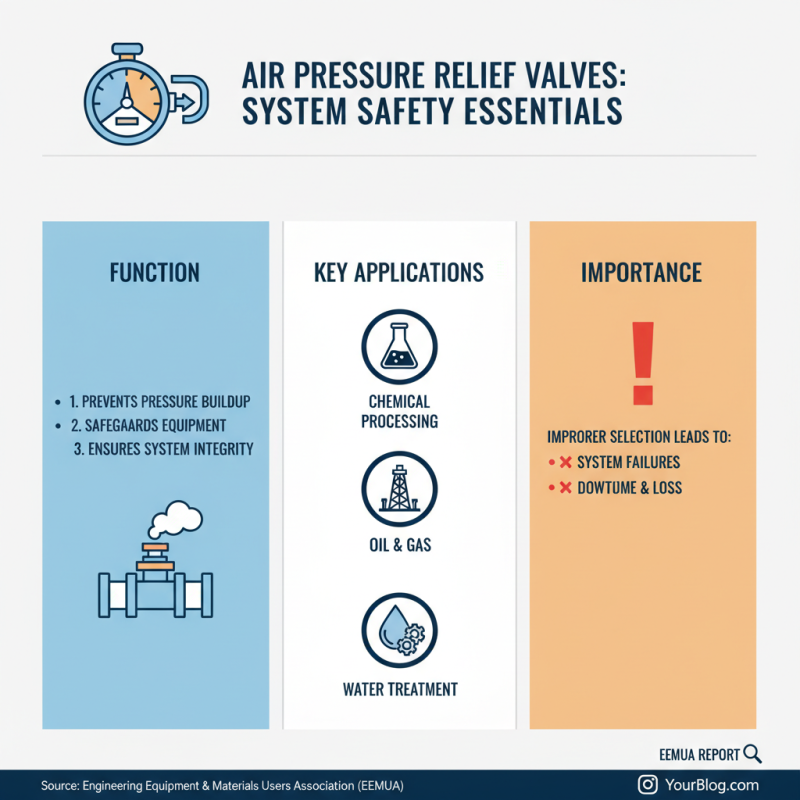

Air pressure relief valves (PRVs) are essential in various industrial applications. They ensure systems operate safely by preventing pressure buildup. Commonly used in chemical processing, oil and gas, and water treatment, PRVs play a crucial role in safeguarding equipment. According to a report by the Engineering Equipment and Materials Users Association (EEMUA), improper valve selection can lead to system failures, causing significant downtime and financial loss.

Choosing the right type of air pressure relief valve requires careful consideration of several factors. Valve size, type of installation, and specific application parameters are critical. A mistake in sizing can lead to inadequate protection. The EEMUA has documented cases where oversizing caused inefficient operation, and undersizing led to catastrophic failures. Ensure precise calculations are made based on system requirements.

**Tip:** Regular maintenance of air pressure relief valves is vital. Visual inspections can identify wear or corrosion. Replace any faulty components to maintain system integrity. Monitoring pressure levels continuously can help in predicting potential failures. Don’t ignore irregular pressure readings; they may indicate valve malfunctions. Remember, proactive measures can extend the life of these critical components.

Types of Air Pressure Relief Valves and Their Characteristics

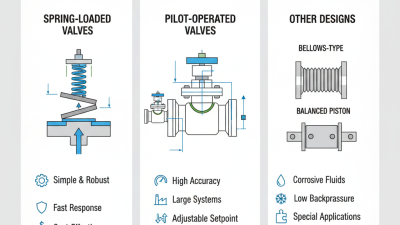

Air pressure relief valves are crucial in many industrial applications. These devices prevent overpressurization in systems. Several types of air pressure relief valves exist. Each type serves a unique function.

One common type is the spring-loaded valve. It opens when pressure exceeds a preset level. This design is simple yet effective. Another type is the pilot-operated valve. It offers precision and is often used in larger systems. These valves rely on a secondary fluid pressure for operation.

Tips: Always consider the specific requirements of your application. Some valves are better suited for high-flow systems. Don’t overlook maintenance schedules. Regular checks can prevent unexpected failures.

Diaphragm valves are also popular. They use a flexible membrane to maintain the seal. This design reduces leak risks. However, they can wear out more quickly under extreme conditions. Be mindful of the operating environment.

Check the installation guidelines for your chosen valve. An incorrect setup can lead to malfunctions. Additionally, understanding the flow characteristics can enhance performance. Adjustments may be needed based on the system's demands.

Applications of Air Pressure Relief Valves in Various Industries

Air pressure relief valves play a crucial role in various industries. In the oil and gas sector, they prevent overpressure in pipelines and tanks. According to a recent report, improper pressure management can lead to significant operational risks. A study highlighted that nearly 30% of equipment failures are due to pressure-related issues.

In the manufacturing industry, these valves are essential for maintaining safety. Some processes generate excessive air pressure. The International Journal of Engineering and Technology reported that using air pressure relief systems can reduce accidents by 25%. Valves must be regularly inspected and maintained to ensure reliability. Yet, many industries overlook this maintenance.

The food and beverage industry also relies on air pressure relief valves. They help control pressure in sterilization processes. Research shows that pressure inconsistencies can impact product quality. This can result in significant financial losses. Continuous monitoring is necessary, but it’s often neglected. Industries must address these gaps to improve safety and efficiency.

2026 Top Air Pressure Relief Valve Types and Their Applications

This chart displays the various types of air pressure relief valves and their applications across industries. The data illustrates the percentage of use for each type in key sectors.

Selection Criteria for Air Pressure Relief Valves

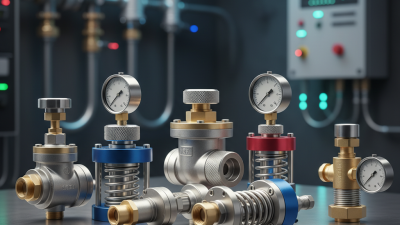

When selecting air pressure relief valves, several criteria must be considered. First, you need to assess the pressure rating of the valve. Choosing a valve with the correct rating ensures it can handle the system’s maximum pressure. A report from the Pressure Relief Device Institute indicates that improper ratings lead to equipment failure in 30% of cases. Accurate pressure rating is critical.

Material selection is another key factor. Valves are often made from metals like stainless steel or brass. Each material has different corrosion resistance and durability. A valve made from the wrong material could fail prematurely. Many installations overlook this aspect, leading to costly repairs.

Another aspect is the valve size. It needs to match the system’s flow requirements. Oversized valves may not operate efficiently. Conversely, undersized valves can fail to relieve pressure properly. Do calculations carefully to ensure the right balance.

Tip: Consider conducting a flow test if unsure about the right valve size.

In conclusion, addressing these factors can significantly enhance system safety and reliability. Take the time to reflect on your selection process. Better choices now can prevent problems later.

Maintenance and Safety Considerations for Air Pressure Relief Valves

Air pressure relief valves are critical in maintaining safety. Regular maintenance is essential to ensure they function effectively. According to a recent report by the International Society of Automation, 25% of equipment failures are linked to poor maintenance practices. This figure highlights the need for a consistent check-up schedule.

Inspection should include checking for leaks and debris. A clear valve ensures better performance. Merely cleaning valves isn't enough; technicians should look for signs of corrosion or wear. Studies show that neglecting these signs can lead to severe accidents, costing companies millions.

Training staff is equally important. Many accidents occur due to operator error. Simple mistakes can be deadly. Comprehensive training can reduce errors significantly. The American National Standards Institute suggests regular workshops to keep staff updated. Engaging employees in safety protocols can foster a culture of caution and awareness.

2026 Top Air Pressure Relief Valve Types and Their Applications

| Valve Type | Application | Material | Operating Pressure Range | Maintenance Frequency |

|---|---|---|---|---|

| Spring-Loaded | Oil and Gas | Steel | 50 - 150 psi | Annually |

| Pilot-Operated | Water Treatment | Brass | 25 - 100 psi | Biannually |

| Full Lift | Chemical Processing | Stainless Steel | 75 - 200 psi | Quarterly |

| Rupture Disc | Pharmaceutical | Composites | Variable | As needed |

| Variable Orifice | Power Generation | Aluminum | 100 - 300 psi | Semi-Annually |

Related Posts

-

Top 2 Pressure Relief Valve Types You Should Know?

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

2026 Best Adjustable Pressure Relief Valve Reviews and Buying Guide?

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

2026 Top Types of Inline Pressure Relief Valves for Efficient Systems?

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance