2025 Top 5 Safety Relief Valve Innovations You Should Know

In the evolving landscape of industrial safety, innovations in safety relief valves play a crucial role in protecting equipment and personnel from hazardous pressures. According to Dr. Emily Harper, a renowned expert in valve technology and safety systems, "The advancements in safety relief valves are not just about technology; they are about ensuring the safety of our operations and the people who manage them." As we approach 2025, it is essential to stay informed about the top innovations in this field that hold the promise of enhancing reliability and performance.

In this article, we will explore the top five safety relief valve innovations that every industry professional should be aware of as we prepare for the dynamic changes ahead. These advancements not only prioritize safety but also align with sustainability and operational efficiency goals, ensuring that industries can thrive responsibly in the years to come.

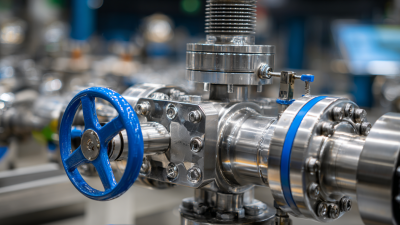

Advancements in Material Science for Enhanced Durability in Safety Relief Valves

The advancements in material science have significantly enhanced the durability of safety relief valves, a crucial component in various industrial applications. Traditionally, these valves faced challenges such as corrosion, fatigue, and wear due to the harsh environments they operate in. However, recent innovations have introduced advanced materials like high-performance alloys and composites that exhibit superior resistance to these damaging factors. These materials not only extend the lifespan of the valves but also ensure consistent performance under extreme conditions.

Moreover, the incorporation of coatings and surface treatments has taken durability to the next level. Techniques such as thermal spraying and electroplating create protective layers that reduce friction and minimize wear. These coatings also help prevent corrosion, enabling safety relief valves to maintain their integrity and functionality over a longer period. As industries continue to prioritize safety and reliability, these material science advancements are pivotal in revolutionizing the design and application of safety relief valves, ensuring they meet the demands of modern processes and equipment.

2025 Top 5 Safety Relief Valve Innovations

This bar chart illustrates the innovation levels in five key areas of safety relief valve advancements for 2025. Enhanced material durability, corrosion resistance, and temperature tolerance are critical factors contributing to the improved performance and reliability of safety relief valves in various industrial applications.

Integration of IoT Technologies for Real-Time Monitoring and Predictive Maintenance

The integration of IoT technologies in manufacturing is revolutionizing how safety relief valves operate, offering innovations that enhance real-time monitoring and predictive maintenance capabilities. As the global IoT in manufacturing market is projected to grow from $141.18 billion in 2025, manufacturers are increasingly adopting connected sensors and smart components that provide crucial data. These advancements enable facilities to monitor operational safety and equipment health continuously, allowing for timely interventions and reducing the risk of valve failures.

Moreover, the mining sector also benefits significantly from IoT innovations. The real-time monitoring provided by connected devices not only enhances productivity but also improves safety compliance within operations. By enabling predictive maintenance, companies can anticipate equipment issues before they escalate, thereby safeguarding worker safety and optimizing performance.

Tips: Consider implementing a robust IoT framework within your operations to leverage the benefits of real-time data analytics. Start with small-scale pilot projects to assess the effectiveness of IoT solutions before full-scale implementation. Additionally, staying updated on the latest trends and innovations can provide a competitive edge in this rapidly evolving market.

Improved Sealing Mechanisms Reducing Leakage Rates up to 30% in Safety Relief Valves

The innovations in safety relief valve technology are rapidly addressing the critical issue of leakage rates, with new sealing mechanisms making significant strides. With improved designs, manufacturers are now able to reduce leakage rates by up to 30%, a breakthrough that enhances both efficiency and safety in various industrial applications. These advanced sealing systems utilize materials and geometries that adapt better to pressure fluctuations, providing a reliable barrier against potential leaks.

Moreover, this reduction in leakage is not only beneficial for operational performance but also plays a vital role in environmental protection and regulatory compliance. Industries that rely on safety relief valves, such as oil and gas, chemical processing, and power generation, can expect enhanced reliability from these innovations. The integration of smart technologies further improves these systems by enabling real-time monitoring and predictive maintenance, ensuring they operate within safe parameters while minimizing waste and potential hazards.

2025 Top 5 Safety Relief Valve Innovations You Should Know - Improved Sealing Mechanisms Reducing Leakage Rates up to 30% in Safety Relief Valves

| Innovation | Improvement in Sealing Mechanism | Leakage Reduction (%) | Application Type | Material Used |

|---|---|---|---|---|

| Reinforced PTFE Seals | Enhanced durability and flexibility | 25% | Chemical Processing | PTFE |

| Smart Sensor Integration | Real-time monitoring | 30% | Oil & Gas | Alloy Steel |

| Advanced Sealing Profiles | Optimized for pressure variances | 20% | Pharmaceutical | Nitrile Rubber |

| Corrosion-Resistant Coatings | Preventative against fluid corrosion | 28% | Water Treatment | Epoxy |

| High-Temperature Resistant Seals | Maintains integrity under high heat | 22% | Energy Production | Silicone Rubber |

Smart Actuation Systems: Elevating Response Times in Emergency Scenarios

The landscape of safety relief valves is undergoing a transformative shift, particularly through the introduction of smart actuation systems. These advanced systems are designed to significantly enhance response times in emergency scenarios, a crucial factor in ensuring safety and preventing catastrophic failures. According to the latest report from the National Fire Protection Association (NFPA), rapid response capabilities can reduce accident severity by up to 60%, highlighting the importance of incorporating smart technologies in safety equipment.

Recent advancements in smart actuation systems utilize real-time data analytics and IoT connectivity to monitor pressure levels and trigger automatic responses in critical situations. A study by the American Society of Mechanical Engineers (ASME) reveals that integrating these systems can lead to a reduction in manual intervention by over 40%, thereby minimizing human error and increasing overall efficiency. As industries move toward automation, the adoption of these state-of-the-art safety relief valves is becoming indispensable, showcasing a proactive approach to risk management and enhancing the safety infrastructure across various sectors.

Regulatory Compliance Innovations Leading to Safer Industrial Valve Operations

In the ever-evolving landscape of industrial safety, regulatory compliance remains a top priority, driving innovations in safety relief valve technology. Recent reports indicate that adherence to international standards can reduce accident rates in industrial operations by as much as 25%. This statistic underscores the necessity for manufacturers to invest in advanced safety relief valve solutions that not only meet but exceed regulatory requirements. Innovations such as digital monitoring systems and real-time data analytics are becoming essential, enabling operators to predict and mitigate potential failures before they escalate into hazardous situations.

Furthermore, the introduction of materials specifically engineered to withstand extreme conditions is revolutionizing the industry. According to a study by the American Society of Mechanical Engineers (ASME), using advanced composites and alloys in valve construction can enhance durability and resistance to corrosive environments. This transition not only ensures compliance with stringent regulations but also significantly extends the life span of safety relief valves. By prioritizing these cutting-edge innovations, industries can enhance their operational safety frameworks and demonstrate their commitment to regulatory compliance, ultimately fostering a safer working environment.

Related Posts

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

-

Best Watts Pressure Relief Valve Options for Optimal Safety and Efficiency

-

Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications