2025 Top 10 Hydraulic Relief Valves: Your Ultimate Guide to Selection

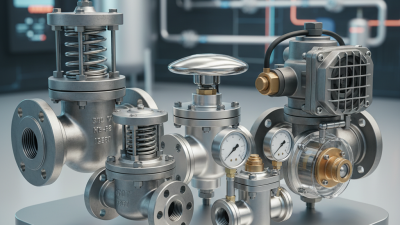

In the ever-evolving landscape of hydraulic systems, understanding the intricacies of hydraulic relief valves is crucial for professionals and enthusiasts alike. As we approach 2025, the selection of the right hydraulic relief valve can significantly impact the efficiency and safety of hydraulic applications. According to renowned industry expert Dr. Jane Thompson, "The choice of a hydraulic relief valve can make or break the overall performance of a hydraulic system." Her insights underline the importance of selecting a valve that not only meets the specifications of a system but also aligns with the operational demands it will face.

When evaluating the top hydraulic relief valves for 2025, it is essential to consider factors such as pressure regulation, flow capacity, and response times. These elements play a pivotal role in ensuring optimal functionality and protecting equipment from potential damage due to pressure surges. This guide aims to streamline the selection process by highlighting the ten best hydraulic relief valves, providing detailed specifications and user assessments, and ensuring that both novices and seasoned professionals can make informed decisions in their hydraulic applications. As we delve into this comprehensive guide, keep in mind that the right hydraulic relief valve is not merely a component; it is a cornerstone of safe and efficient hydraulic operation.

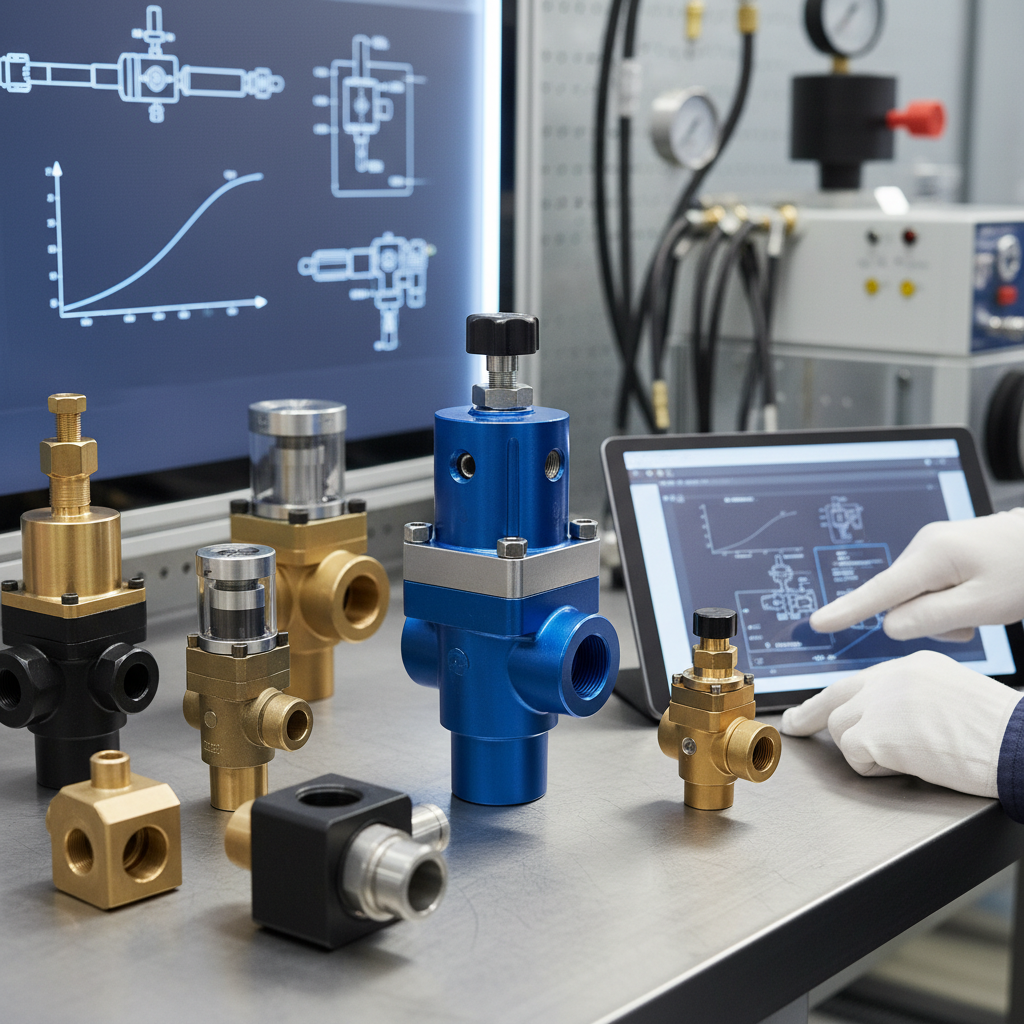

Top Features to Consider in Hydraulic Relief Valves

When selecting hydraulic relief valves, several key features must be prioritized to ensure optimal performance and safety in hydraulic systems. One of the most critical factors is the valve's setting pressure range. A valve that can adjust between various pressure levels allows for greater flexibility in system operations, accommodating different pressures that may occur during process changes or unforeseen surges.

Another essential feature to consider is the valve's response time. A quick response is crucial for maintaining stability within the hydraulic system, as it helps prevent pressure spikes that can damage equipment. Additionally, the construction material of the valve plays a significant role in its durability and resistance to corrosion. Opting for valves made from high-quality materials such as stainless steel or brass can enhance the longevity of the system, especially in harsh or corrosive environments. Lastly, ease of installation and maintenance is also vital; a design that facilitates straightforward setup and servicing can significantly reduce downtime and costs in industrial operations.

2025 Top 10 Hydraulic Relief Valves: Your Ultimate Guide to Selection - Top Features to Consider in Hydraulic Relief Valves

| Model | Pressure Range (psi) | Flow Rate (GPM) | Adjustment Type | Material | Temperature Range (°F) |

|---|---|---|---|---|---|

| Model A | 500 - 3000 | 10 | Manual | Aluminum | -20 to 200 |

| Model B | 750 - 2500 | 15 | Spring Loaded | Steel | -10 to 180 |

| Model C | 1000 - 3500 | 20 | Electro-Hydraulic | Stainless Steel | -40 to 250 |

| Model D | 600 - 2000 | 12 | Fixed | Aluminum | -20 to 190 |

| Model E | 800 - 3000 | 25 | Adjustable | Carbon Steel | 0 to 220 |

Understanding Different Types of Hydraulic Relief Valves

When selecting hydraulic relief valves, it is essential to understand the different types available. The primary categories include direct-acting, pilot-operated, and balanced poppet valves. Direct-acting relief valves provide quick response times and are often used in applications requiring immediate pressure relief. Conversely, pilot-operated relief valves utilize a pilot line to sense pressure changes, allowing them to handle larger flow rates and providing greater efficiency in larger systems.

**Tips:** When choosing a relief valve, consider the specific application and the pressure requirements. It's crucial to match the valve's specifications to your system's operating conditions to ensure reliability and performance.

Another important aspect is the valve's setting range. Some valves are adjustable, allowing for changes in pressure limits to accommodate varying operational needs. This flexibility can be invaluable in dynamic environments where system demands fluctuate. Be sure to review the materials used in the valve's construction as well, as this can impact durability and compatibility with different hydraulic fluids.

**Tips:** Regular maintenance and monitoring of hydraulic relief valves help prevent failures and extend the life of your equipment. Keeping a checklist for inspections can ensure that you catch any irregularities early.

2025 Top 10 Hydraulic Relief Valves: Data Comparison

Key Performance Metrics for Selecting Hydraulic Relief Valves

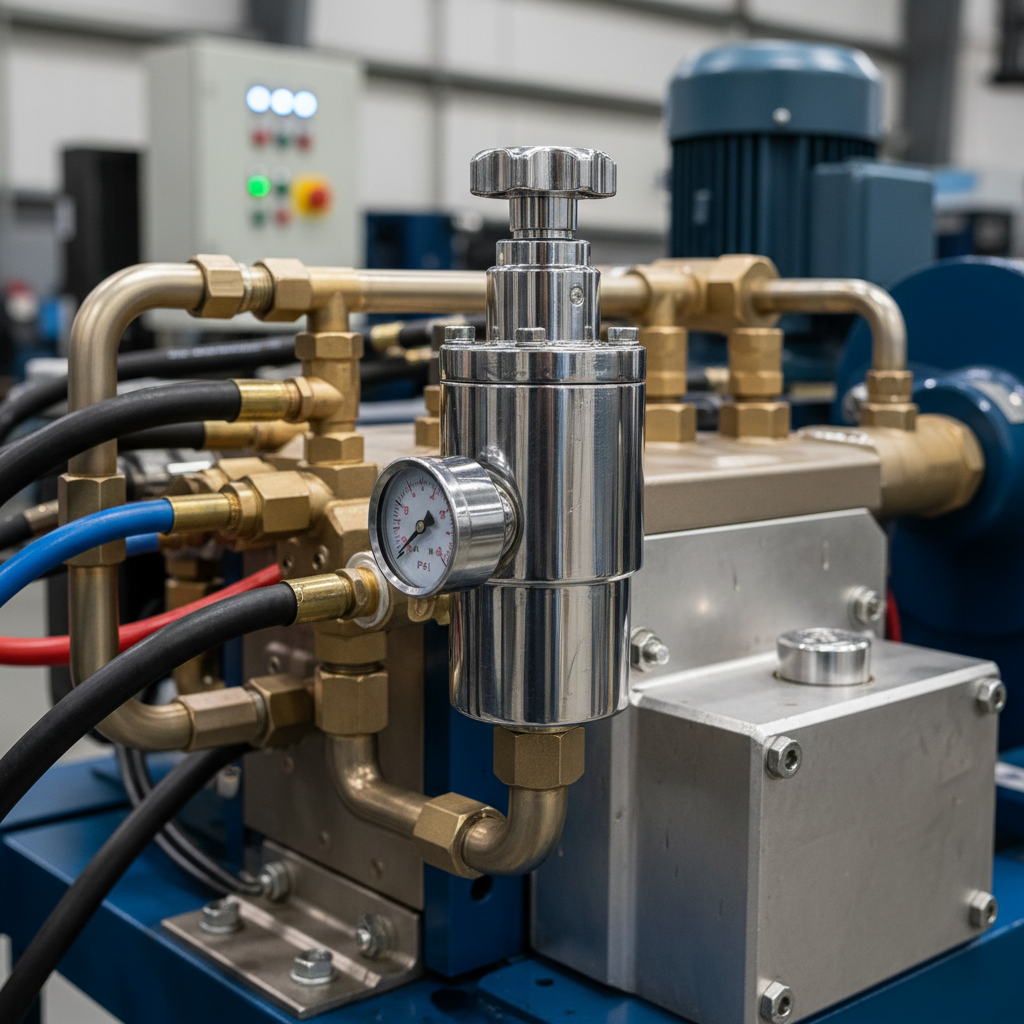

When selecting hydraulic relief valves, understanding key performance metrics is crucial for ensuring optimal system functionality and safety. The primary metric to consider is the pressure setting, which determines at what point the valve will open to relieve excess pressure. This setting must align with the operational limits of the hydraulic system to prevent damage and maintain efficiency. Additionally, the valve's response time is essential; it should promptly react to changes in pressure to avoid pressure spikes that could compromise system integrity.

Another important performance metric is the flow capacity of the relief valve, measured in gallons per minute (GPM) or liters per minute (LPM). This capacity indicates how much fluid the valve can handle when it activates, making it vital for preventing fluid overflow and ensuring smooth operation. Moreover, the valve's construction materials and sealing mechanisms also play a significant role in its durability and performance in various operating environments. Choosing a valve that is compatible with the fluids used and the conditions it will face can significantly extend its lifespan and reduce maintenance needs.

Common Applications for Hydraulic Relief Valves in Industry

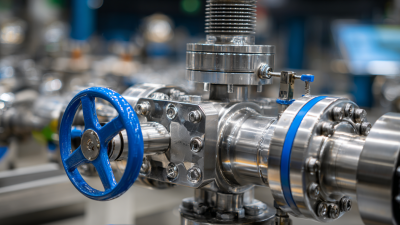

Hydraulic relief valves are crucial components in various industrial applications, helping to protect hydraulic systems from excessive pressure. They are commonly found in industries ranging from manufacturing to construction, ensuring that equipment operates safely and efficiently. In manufacturing, these valves prevent damage to machinery by regulating pressure in hydraulic circuits, allowing for smooth operation and reducing the risk of breakdowns.

**Tip:** When selecting a hydraulic relief valve for manufacturing applications, consider the pressure range and flow characteristics of your system to ensure optimal performance.

In construction, hydraulic relief valves play a vital role in heavy equipment like excavators and bulldozers. These valves prevent hydraulic systems from exceeding safe pressure limits, safeguarding both the equipment and operators from potentially hazardous failures. By maintaining a consistent pressure, they help improve the overall reliability and longevity of the machinery.

**Tip:** Always check the specifications of the hydraulic relief valve to match the demands of your construction equipment, as using the wrong type can lead to inefficient operation or safety issues.

Maintenance Tips for Prolonging the Life of Hydraulic Relief Valves

Maintaining hydraulic relief valves is crucial to ensuring their longevity and optimal performance. Regular maintenance not only extends the life of these components but also enhances the overall efficiency of hydraulic systems. One key tip is to regularly inspect and clean the valves to prevent contaminants from clogging the mechanisms. Dirt and debris can significantly impair the valve function, leading to potential system failures.

Another important aspect of maintenance is to check the valve settings periodically. Ensuring that they are correctly calibrated according to the manufacturer’s specifications helps maintain safe pressure levels within the system. Adjustments may be necessary if the system has undergone any modifications or if the operational environment has changed. Additionally, lubricating the valve parts with appropriate oils can help reduce wear and tear, contributing to smoother operation.

Lastly, keeping an eye on the hydraulic fluid quality is essential. Contaminated or degraded fluid can cause corrosion and damage to the valves. Therefore, scheduling regular fluid changes and filtration will help maintain the health of hydraulic relief valves, ensuring consistent performance and extending their operational lifespan.

Related Posts

-

5 Best Pressure Vacuum Relief Valves for Optimal Safety and Performance in 2023

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

The Essential Role of Vacuum Relief Valves in Ensuring Safety and Efficiency in Industrial Systems

-

Best Watts Pressure Relief Valve Options for Optimal Safety and Efficiency

-

Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications

-

Top 5 Pressure Vacuum Relief Valves: Maximizing Safety and Efficiency