Top 10 Temperature and Pressure Relief Valves to Enhance Safety and Efficiency in Industrial Applications

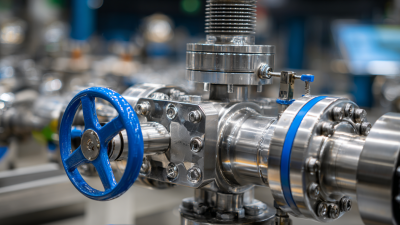

In the industrial sector, maintaining operational safety and efficiency is paramount, particularly in systems involving high temperatures and pressures. The implementation of effective temperature and pressure relief valves (TPRVs) is a critical component of this safety framework, as these devices are designed to safeguard equipment and personnel from hazardous conditions. According to the latest report from the American Society of Mechanical Engineers (ASME), improper pressure control can lead to catastrophic failures, resulting in economic losses of billions of dollars annually. Thus, choosing the right TPRV can significantly mitigate these risks while enhancing process efficiency.

Advancements in material science and engineering design have led to the development of innovative TPRVs that not only comply with stringent safety regulations but also improve system performance. An industry study by the National Fire Protection Association (NFPA) indicates that properly maintained and installed TPRVs can reduce the likelihood of dangerous incidents by up to 60%. In light of these findings, industries such as oil and gas, chemical manufacturing, and power generation are increasingly focused on optimizing their TPRV solutions. This article delves into the "Top 10 Temperature and Pressure Relief Valves" that exemplify safety and efficiency, discussing their features, applications, and how they contribute to the overall integrity of industrial processes.

Understanding the Importance of Temperature and Pressure Relief Valves in Industries

Temperature and pressure relief valves (TPRVs) are critical components in industrial settings, providing essential safety measures that protect equipment and personnel from potential hazards. According to a report by the International Journal of Safety and Security Engineering, failure to use appropriate TPRVs can lead to catastrophic accidents, including explosions and equipment failures, resulting in an average annual industrial loss of $250 million due to equipment malfunctions. These valves serve as the first line of defense against excessive pressure and temperature, ensuring that systems operate within safe limits.

The role of TPRVs extends beyond mere protection; they also enhance operational efficiency. A study conducted by the American Society of Mechanical Engineers (ASME) found that optimizing TPRV functionality can improve system performance by as much as 15%. This efficiency gain translates to increased productivity and reduced downtime, which are crucial in highly competitive industrial sectors. Properly selected and maintained TPRVs not only mitigate risks but also contribute significantly to the bottom line, underscoring their importance in industrial applications.

Top 10 Temperature and Pressure Relief Valves to Enhance Safety and Efficiency in Industrial Applications

| Valve Model | Pressure Range (psi) | Temperature Range (°F) | Material | Application | Compliance Standards |

|---|---|---|---|---|---|

| Model A | 50 - 150 | 100 - 300 | 316 Stainless Steel | Steam Systems | ASME, API |

| Model B | 75 - 200 | 50 - 250 | Bronze | Water Systems | NSF, ANSI |

| Model C | 100 - 300 | 200 - 400 | Carbon Steel | Gas Systems | GOST, ISO |

| Model D | 50 - 175 | 0 - 240 | PVC | Chemical Handling | EPA, CE |

| Model E | 125 - 250 | 100 - 350 | Alloy Steel | Oil & Gas | ASME, NACE |

| Model F | 60 - 180 | 150 - 300 | Composite Material | Pharmaceutical | FDA, cGMP |

| Model G | 80 - 220 | 50 - 270 | Nickel Alloy | Food Processing | HACCP, ISO 22000 |

| Model H | 100 - 250 | 30 - 400 | Titanium | Marine Applications | ABS, DNV GL |

| Model I | 150 - 300 | 75 - 400 | Aluminum | Compressed Air | OSHA, ANSI |

| Model J | 50 - 100 | 0 - 200 | Polypropylene | Environmental Systems | REACH, RoHS |

Key Features to Consider When Choosing Relief Valves for Safety and Efficiency

When selecting temperature and pressure relief valves for industrial applications, safety and efficiency should be at the forefront of decision-making. Key features to consider include the valve's set pressure, flow capacity, and material compatibility. According to a report by the American Society of Mechanical Engineers (ASME), selecting a valve with the appropriate set pressure is critical; valves should be calibrated to open at a pressure that is 10-15% above typical operating conditions to ensure optimal functionality and safety.

In addition, flow capacity is a vital consideration. A valve must be able to release enough fluid to prevent overpressure situations, which is crucial in industries such as chemical manufacturing where the consequences of failure can be catastrophic. It's essential to evaluate the manufacturer's performance data; for instance, a study by the International Society of Automation (ISA) suggests that valves with higher Cv values can significantly improve system reliability and prevent costly downtimes.

Tips: When assessing material compatibility, be aware of the corrosive nature of fluids in your application; choosing the right materials can prolong service life and enhance safety. Additionally, take into account the installation environment; ensure that the valve design accommodates any space constraints while still allowing for easy maintenance access.

Top Recommendations: Best Temperature and Pressure Relief Valves for Industrial Use

When it comes to ensuring safety and efficiency in industrial applications, selecting the right temperature and pressure relief valves (PRVs) is crucial. According to a recent report by the Global Market Insights, the temperature and pressure relief valve market is projected to exceed $5 billion by 2027, driven by increasing safety regulations and the growing demand from crucial industries such as oil and gas, chemical manufacturing, and power generation. These valves not only prevent accidental overpressure situations but also optimize energy consumption and operational efficiency.

Top recommendations for the best temperature and pressure relief valves include models from recognized manufacturers known for their reliability and advanced technology. For instance, the API 520 standards highlight the importance of proper sizing and selection of PRVs, underscoring that an appropriately designed valve can reduce the risk of catastrophic failures by up to 30%. Additionally, valves equipped with smart monitoring systems are gaining popularity, offering real-time data analytics that enhance preventive maintenance and operational insights. These advancements support facilities in not only adhering to safety standards but also improving productivity and cost-effectiveness.

Maintenance Tips for Maximizing the Lifespan of Relief Valves in Operations

Maintenance is crucial for maximizing the lifespan and efficiency of temperature and pressure relief valves in industrial applications. Regular inspections should be a top priority, as these components experience wear over time. Operators should schedule thorough checks at least once every six months to identify any signs of corrosion, leaks, or excessive wear that could hinder performance. Ensuring that the valves are free from debris and obstructions also helps maintain their functionality, allowing them to open and close as intended during pressure fluctuations.

Another essential maintenance tip is to test the valves periodically. This involves simulating the pressure and temperature conditions they are designed to handle. Doing so verifies that the valves respond appropriately to excess pressure or temperature, preventing potential system failures. Additionally, proper documentation of maintenance activities and any repairs conducted can provide valuable insights over time, helping to refine maintenance schedules and improve operational reliability. Implementing these practices will not only extend the lifespan of relief valves but also enhance the overall safety and efficiency of industrial operations.

Top 10 Temperature and Pressure Relief Valves Performance Comparison

This bar chart illustrates the efficiency performance of the top 10 temperature and pressure relief valves in industrial applications. Efficient valves are critical for safety and performance, and the data showcases a comparative analysis among different valve models.

Installation Guidelines for Ensuring Proper Functionality of Relief Valves

Proper installation of temperature and pressure relief valves is essential for ensuring their functionality and enhancing safety in industrial applications. A well-installed valve can prevent hazardous situations by venting excess pressure or temperature, protecting equipment and personnel from potential failures. Start by choosing the right valve that matches your system’s specifications, considering factors such as the maximum allowable pressure and temperature.

Tip: Always install the relief valve in a vertical position to promote effective drainage and minimize the chances of blockages. Ensure that the inlet piping is properly supported to avoid strain on the valve itself, which could lead to leaks or malfunctions over time.

Before installation, it’s crucial to inspect the valve for any signs of damage or wear. Clean the valve seat and the surrounding area to prevent contamination, which can interfere with the valve's operation. After securing the valve, conduct a pressure test to confirm that it opens at the specified pressure and closes properly.

Tip: Implement regular maintenance checks to replace any worn seals or parts, ensuring the relief valve remains functional and reliable over time. Keeping comprehensive documentation of these maintenance activities can aid in troubleshooting and compliance with safety regulations.

Related Posts

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications

-

2025 Top 5 Safety Relief Valve Innovations You Should Know

-

5 Best Pressure Vacuum Relief Valves for Optimal Safety and Performance in 2023