Why is a Pressure Relief Valve Essential for Safety and Performance?

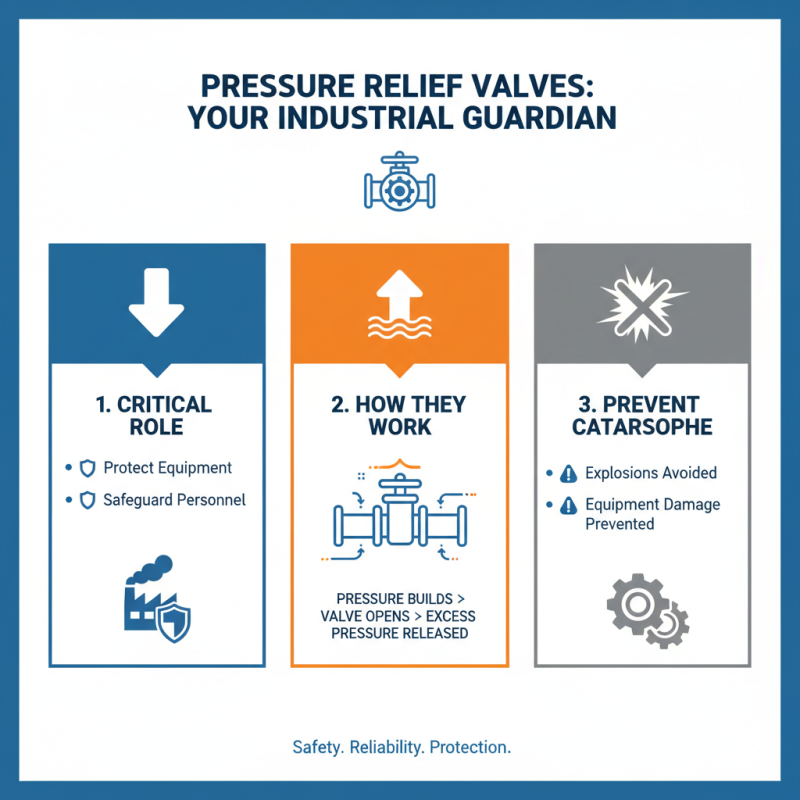

A pressure relief valve is a crucial component in many systems. It acts as a safety mechanism, preventing dangerous pressure buildup. When pressure exceeds safe levels, the valve opens to release excess pressure. This prevents equipment damage and potential safety hazards.

In industrial processes, the pressure relief valve ensures optimal performance. Systems can operate efficiently without the risk of failure. Yet, many overlook its importance until a crisis occurs. A faulty valve can lead to catastrophic results, including explosions or leaks. Regular maintenance and testing are essential to ensure reliability.

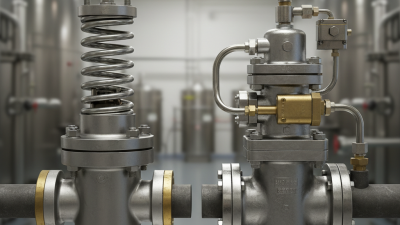

The effectiveness of a pressure relief valve can be affected by various factors. Installation errors, corrosion, and wear can compromise its function. It is vital to assess the condition of these valves regularly. By doing so, we acknowledge that safety and performance are intertwined. Investing in quality pressure relief valves can save time and resources in the long run.

Importance of Pressure Relief Valves in Industrial Applications

Pressure relief valves play a critical role in various industrial applications. They are designed to protect equipment and personnel. When pressure builds up beyond safe levels, these valves safely release excess pressure. This action prevents catastrophic failures, such as explosions or equipment damage.

In manufacturing plants, pressure relief valves are essential. They are installed in boilers, tanks, and pipelines. A malfunctioning valve can lead to dangerous situations. Operators must regularly inspect and maintain these devices. Even minor issues can escalate quickly. The cost of preventive maintenance is often far less than repairs from an accident.

Training staff on the importance of these valves is vital. Employees should understand how they function. They must know when to inspect them. Investing in safety training creates a culture of caution. This awareness should never be taken for granted. Ultimately, the effectiveness of pressure relief valves influences overall safety and performance in the workplace.

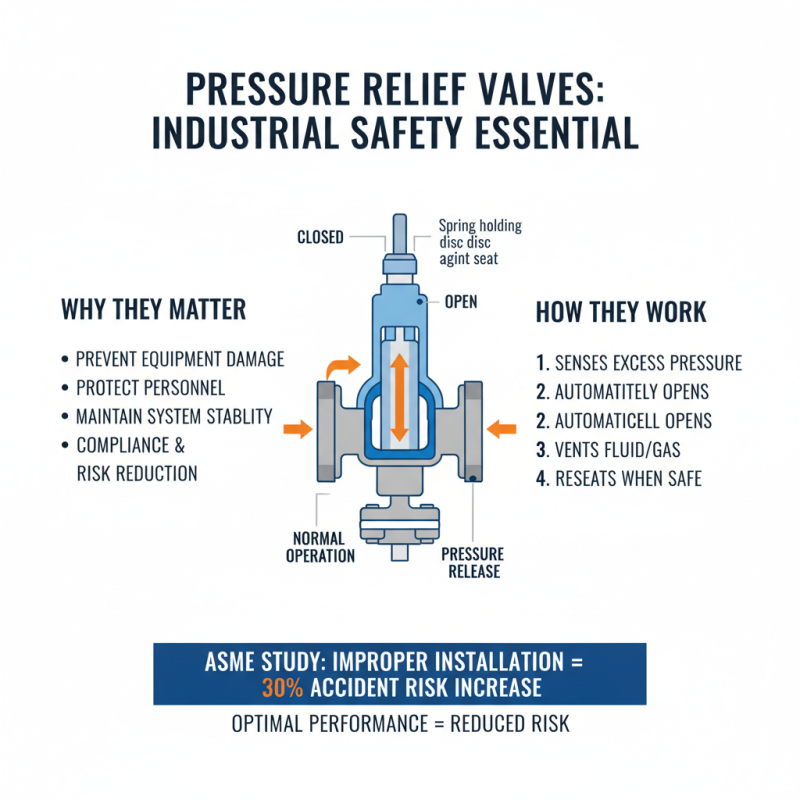

Understanding the Mechanism of Pressure Relief Valve Operation

Pressure relief valves (PRVs) are crucial for maintaining safety in various industrial applications. They help control excess pressure by venting it safely. Understanding their operation is vital for optimal performance and risk reduction. For example, a study by the American Society of Mechanical Engineers indicates that improper PRV installation can lead to a 30% increase in accident risk.

The mechanism of a pressure relief valve is relatively straightforward. When the pressure in a system exceeds its designated limit, the valve opens. This releases the excess pressure, preventing catastrophic failures. However, the settings and calibration of these valves can sometimes be overlooked. Many facilities experience problems due to incorrect adjustment. This can lead to either too much pressure being retained or unnecessary discharges.

It's essential to regularly inspect and maintain PRVs. A report by the National Board of Boiler and Pressure Vessel Inspectors shows that nearly 40% of PRVs fail to operate correctly due to lack of maintenance. Regular checks can prevent unforeseen problems. Operators must be vigilant. Relying solely on pressure relief valves without proactive measures is risky.

Key Industry Standards Governing Pressure Relief Valve Usage

Pressure relief valves are critical to maintaining safe operations in various industries. These devices protect systems from extreme pressure by releasing excess pressure. When not functioning properly, they can cause catastrophic failures. It’s essential to comply with industry standards to ensure reliability and safety.

Regulatory bodies establish guidelines for pressure relief valve installation and maintenance. For instance, many industries adhere to standards set by organizations like ASME. These guidelines dictate the design, testing, and documentation required for pressure relief valves. Consistent failures may stem from overlooking these standards. Some companies might disregard them, thinking their systems are inherently safe.

Regular inspections and employee training are vital yet often neglected. Facilities may miss critical updates that could enhance safety. Some operators may skip training, assuming their experience suffices. Such complacency leads to increased risks. The pressure relief valve's role cannot be understated; it is key for preventing dangerous situations. All stakeholders should prioritize adherence to standards and continuous improvement.

Data on Failure Rates and Incidents Without Pressure Relief Valves

Pressure relief valves are crucial for maintaining safety in various systems. Without these devices, pressures can soar to dangerous levels. This can lead to catastrophic failures. Data shows that incidents often occur in systems lacking pressure relief mechanisms. Various industries have reported alarming failure rates, highlighting the risks involved.

In one study, a significant percentage of incidents occurred due to excessive pressure buildup. Systems like boilers and pipelines have failed severely, causing injuries and property damage. When examining these failures, many lacked proper safety equipment. The consequences raise questions about operational practices and compliance.

While some organizations understand the importance of pressure relief valves, not all implement them correctly. Training and maintenance often fall short. Regular inspections are vital, yet they can be overlooked. The data serve as a stark reminder: safety must always be prioritized.

Why is a Pressure Relief Valve Essential for Safety and Performance?

| Incident Type | Failure Rate (%) | Impact Severity (Scale 1-5) | Cost of Incident ($) | Reported Cases per Year |

|---|---|---|---|---|

| Explosions due to overpressure | 15% | 5 | 1,000,000 | 200 |

| Equipment damage | 25% | 4 | 250,000 | 500 |

| Personal injuries | 10% | 5 | 500,000 | 100 |

| Regulatory fines | 8% | 3 | 100,000 | 50 |

| Loss of production | 20% | 4 | 750,000 | 300 |

Impact of Pressure Relief Valves on System Efficiency and Reliability

Pressure relief valves play a crucial role in maintaining system efficiency. They are designed to control excess pressure. When a system exceeds its safe pressure limit, these valves automatically open. This prevents potential failures and accidents. Without them, equipment may suffer damage, leading to costly downtime.

Reliability is also heavily influenced by these valves. A malfunctioning valve can result in pressure build-up. This can cause leaks, ruptures, or total equipment failure. Regular maintenance checks are necessary. However, some operators overlook this task. Consequently, systems can become less efficient over time.

Consider a closed system without a pressure relief mechanism. If pressure continues to build, components may fail suddenly. This can cause operational havoc. An effective valve minimizes the risks of such scenarios. Ensuring these devices function as intended is vital for safety and performance. Regular inspections can reveal hidden issues. They remind operators that even small oversights can have major consequences.

Impact of Pressure Relief Valves on System Efficiency and Reliability

Related Posts

-

Top 2 Pressure Relief Valve Types You Should Know?

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

Ultimate Guide to Pressure Relief Valve Selection and Maintenance Tips