Understanding the Importance of Relief Valves in Industrial Applications

In industrial applications, the significance of relief valves cannot be overstated, as they play a crucial role in maintaining safety and efficiency within pressurized systems. According to a report by the International Society of Automation, improper pressure management can lead to catastrophic failures, costing industries millions in downtime and repairs. Relief valves are designed to protect equipment from overpressure conditions, thereby preventing potential hazards such as explosions or equipment malfunctions. The American Society of Mechanical Engineers (ASME) estimates that approximately 5% of all industrial accidents are related to pressure failures, underscoring the need for properly functioning relief valves. This essential component not only ensures compliance with safety regulations but also enhances operational reliability, making it imperative for industrial operators to understand their critical importance in process safety management.

The Critical Role of Relief Valves in Industrial Safety

Relief valves play a pivotal role in ensuring industrial safety by preventing the catastrophic consequences of pressure build-up in various systems. According to a report by the American Society of Mechanical Engineers (ASME), over 80% of equipment failures in high-pressure environments can be traced back to inadequate pressure control. Relief valves are specifically designed to divert excess pressure away from critical equipment, thereby minimizing the risk of explosions or system failures. Their presence is not just a regulatory requirement; it is a key component in safeguarding both personnel and infrastructure in facilities spanning oil and gas, chemical manufacturing, and pharmaceuticals.

Moreover, the National Fire Protection Association (NFPA) estimates that proper installation and maintenance of relief valves could reduce the likelihood of pressure-related incidents by up to 60%. In industries where the cost of downtime can soar into millions, the reliability and functionality of relief valves directly impact operational efficiency and safety. By undertaking regular inspections and ensuring compliance with standards set forth by organizations like the Occupational Safety and Health Administration (OSHA), industries can maintain an effective defense against the unpredictable nature of pressure fluctuations, thereby fortifying the overall integrity of their operations.

Importance of Relief Valves in Industrial Safety

Top 5 Benefits of Implementing Relief Valves in Workplaces

Relief valves are critical components in industrial applications, serving as essential safety mechanisms that prevent system failures and accidents. Implementing these devices not only safeguards equipment but also enhances workplace culture by providing an outlet for employee frustrations. This correlation emphasizes the first benefit: the promotion of a safer workplace environment. When employees feel that their voices are heard, they are less likely to experience stress-related issues, which ultimately contributes to improved overall safety.

Moreover, relief valves enable better system performance and reliability. They allow for controlled pressure release, thereby preventing catastrophic failures that can lead to downtime and costly repairs. In a similar vein, workplaces that cultivate open communication channels—akin to installing relief valves—encourage employees to voice their concerns. This practice leads to quicker problem-solving and innovation, as employees are more likely to contribute ideas when they feel comfortable expressing their thoughts. Therefore, the integration of relief valves and a culture of transparency can significantly enhance both operational efficiency and employee satisfaction.

3 Common Types of Relief Valves and Their Applications

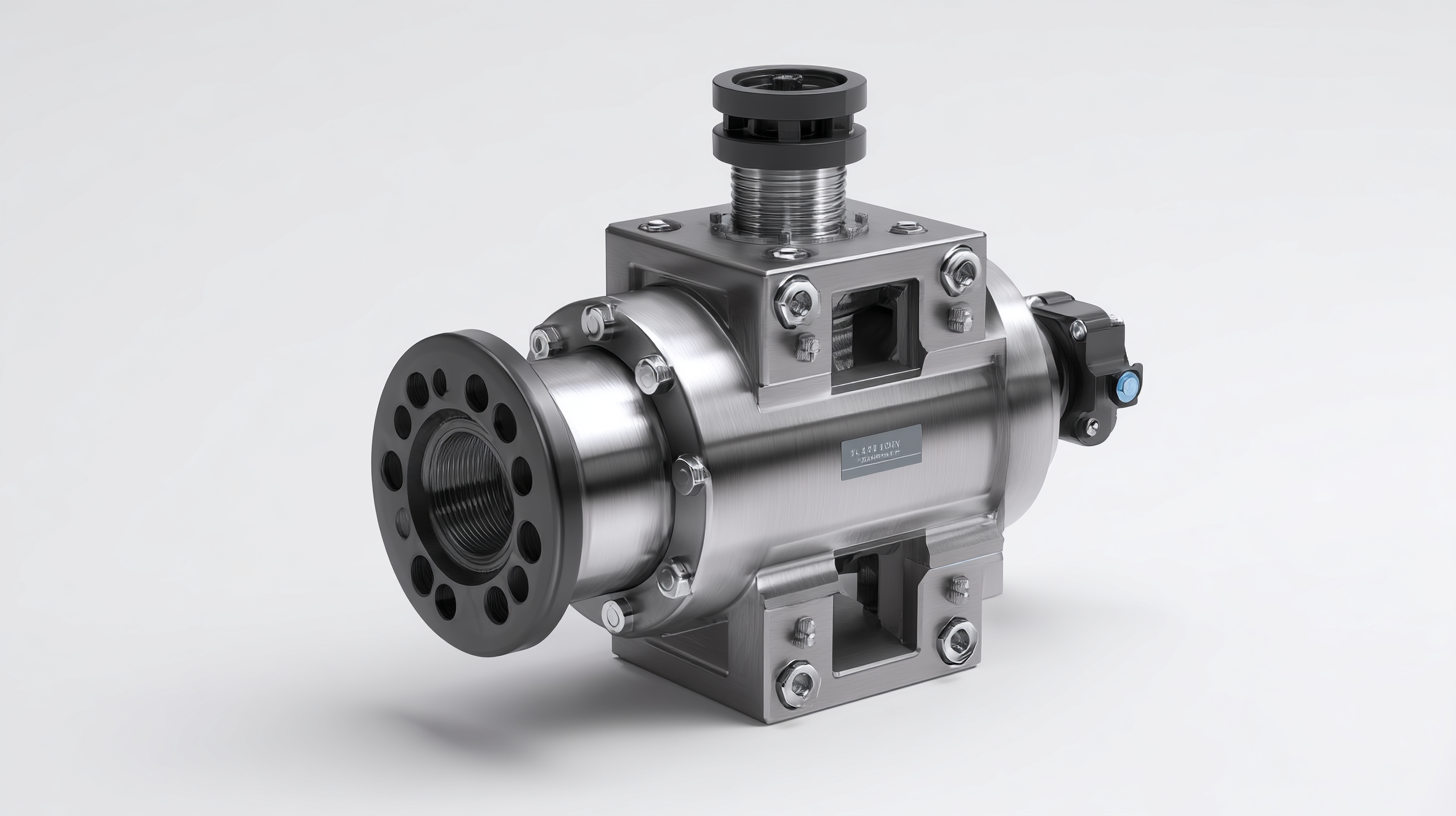

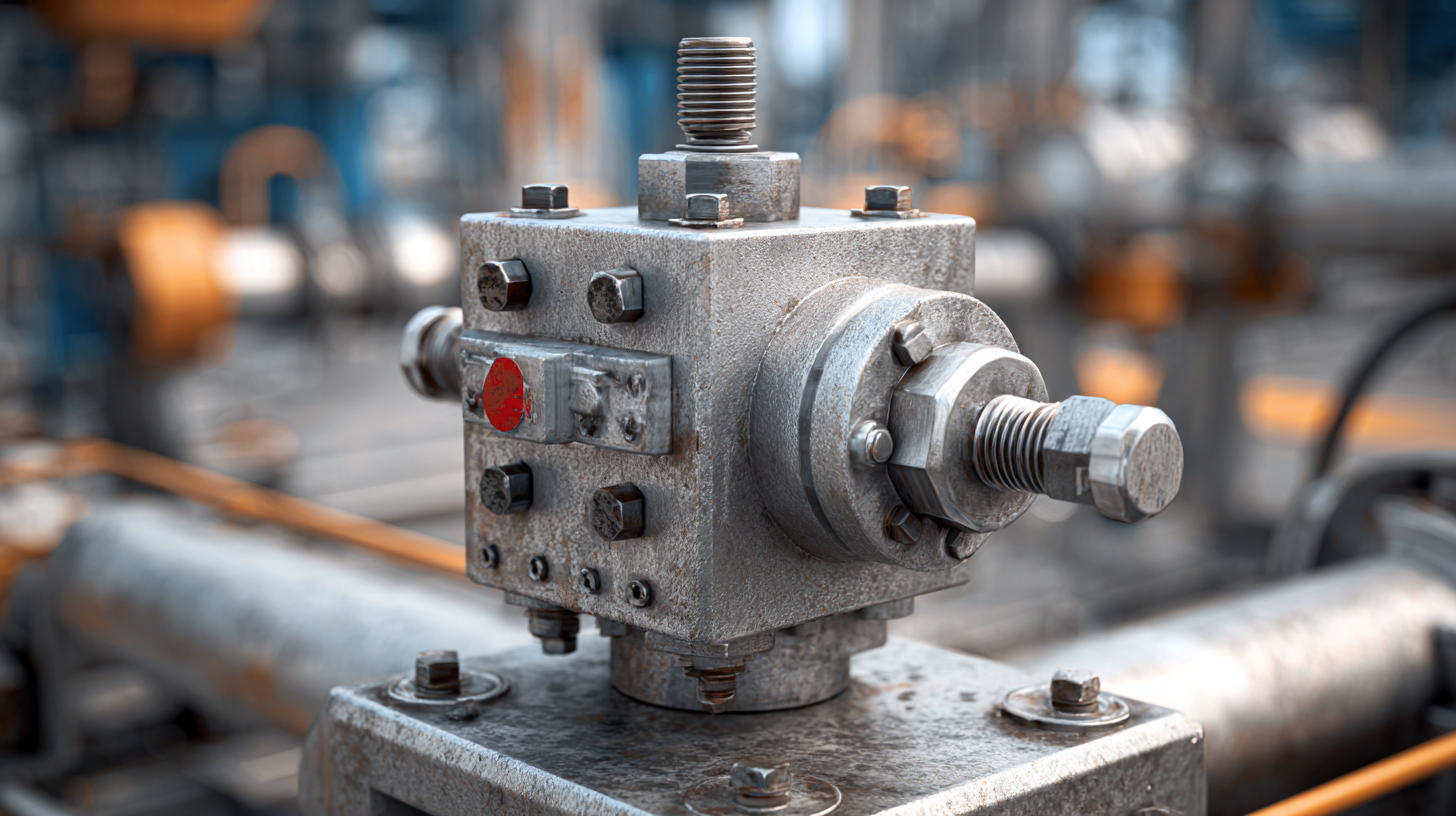

Relief valves are critical components in industrial systems, designed to protect equipment and maintain safety by controlling pressure levels. There are three common types of relief valves: pressure relief valves, thermal relief valves, and safety relief valves, each serving distinct purposes in various applications.

Pressure relief valves are primarily used in systems where excess pressure needs to be managed, such as in boilers and pressure vessels. These valves open to release excess pressure when a predetermined limit is reached, thus preventing potential equipment failure or explosions. Thermal relief valves, on the other hand, are essential in systems where temperatures can cause pressure fluctuations, particularly in closed-loop systems like hydraulic circuits. By allowing fluid to escape when temperatures rise, these valves help maintain safe operating conditions.

Pressure relief valves are primarily used in systems where excess pressure needs to be managed, such as in boilers and pressure vessels. These valves open to release excess pressure when a predetermined limit is reached, thus preventing potential equipment failure or explosions. Thermal relief valves, on the other hand, are essential in systems where temperatures can cause pressure fluctuations, particularly in closed-loop systems like hydraulic circuits. By allowing fluid to escape when temperatures rise, these valves help maintain safe operating conditions.

Finally, safety relief valves are crucial in applications like natural gas and oil pipelines. They provide an additional layer of safety by opening to release pressure quickly in emergencies, ensuring that the system remains within safe operational limits. Understanding these three types of relief valves and their specific applications is essential for maintaining efficiency and safety in industrial operations.

Key Maintenance Practices for Ensuring Relief Valve Efficiency

Relief valves are critical components in industrial systems, designed to prevent overpressure conditions that could lead to catastrophic failures. To ensure their efficiency, regular maintenance is essential. One key maintenance practice is the routine inspection of the valve’s seating and sealing surfaces. Any signs of wear, corrosion, or damage can severely impact the valve's ability to function correctly. Implementing a schedule for these inspections can help identify issues before they lead to failure.

Another important practice is testing the relief valve's performance at predetermined intervals. This involves verifying its set pressure and ensuring that it opens and closes as intended. Utilizing test stands or pressure devices can provide accurate measurements, helping maintain the valve's reliability in critical situations. Additionally, proper documentation of maintenance activities helps track the valve's performance history, making it easier to predict when a replacement or overhaul might be necessary. By adhering to these maintenance practices, industries can significantly enhance the safety and effectiveness of their relief valves.

Understanding Pressure Regulation: Relief Valves in System Design

Relief valves play a critical role in pressure regulation within industrial systems, ensuring operational safety and efficiency. These valves function to manage excess pressure, preventing potential failures by redirecting the flow of fluids when the pressure exceeds preset limits. This mechanism is essential in protecting equipment and infrastructure from the damaging effects of overpressure, which can lead to catastrophic failures, costly shutdowns, or even hazardous situations.

In system design, the integration of relief valves must be carefully considered. Selecting the right type of valve and correctly positioning it within the system are crucial to achieving optimal performance. Engineers must analyze system parameters, including fluid characteristics, operating pressures, and potential pressure surges, to ensure the relief valve provides effective protection without compromising system efficiency. Proper implementation of relief valves ultimately enhances the reliability of industrial operations, allowing facilities to meet safety regulations while maintaining productivity.

Related Posts

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance