Understanding the Importance of Air Compressor Relief Valve in 2025 Top Models

In the realm of pneumatic systems, the air compressor relief valve stands as a critical component, ensuring both performance and safety across various applications. As we approach 2025, understanding the role and functionality of this valve becomes increasingly pertinent, especially with advancements in compressor technology. The air compressor relief valve is designed to prevent excessive pressure buildup within the system, safeguarding not only the equipment but also the operators who rely on these machines.

In this evolving landscape, where efficiency and reliability are paramount, choosing the right models equipped with superior relief valves can greatly enhance operational productivity. This article explores the fundamental significance of the air compressor relief valve, examining its function in maintaining optimal pressure levels, preventing potential hazards, and contributing to the longevity of the compressor itself. As we delve into the top models of 2025, we will highlight how effective relief valves serve as the backbone of safe and efficient air compression systems, ensuring they perform reliably under pressure.

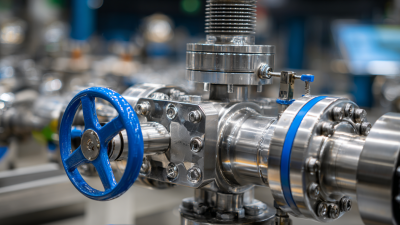

The Role of Air Compressor Relief Valves in Safe Operation

The relief valve is a crucial component in air compressors, primarily ensuring safe operation by preventing excessive pressure buildup within the system. In 2025's top models, these valves are designed with advanced mechanisms that minimize the risk of catastrophic failures. By automatically releasing air when pressure exceeds a predetermined limit, relief valves provide a fail-safe that protects both the equipment and users from potential hazards. This not only enhances the durability of the compressor but also significantly reduces the likelihood of accidents in industrial settings.

Moreover, the role of air compressor relief valves extends beyond just pressure regulation. They contribute to the overall efficiency of the air compressor by maintaining optimal operating conditions. In scenarios where pressure levels fluctuate, the relief valve ensures a consistent output, preventing wastage of energy and resources.

As manufacturers continue to innovate in 2025, incorporating smarter technology and materials into these valves, their reliability and responsiveness are expected to increase, furthering their importance in safe compressor operation. In essence, the relief valve stands as a sentinel, safeguarding both operator and equipment while promoting a sustainable working environment.

Key Features of Top Air Compressor Models with Relief Valves

The air compressor relief valve is a crucial component in maintaining the safety and efficiency of air compressor systems. In 2025, leading models incorporate advanced relief valve designs that not only prevent over-pressurization but also enhance operational reliability. According to the Air Compressors Market Report 2023, approximately 20% of compressor failures are attributed to inadequate relief systems, underscoring the need for robust safety features in modern designs. With a focus on user safety, top models now feature dual-stage pressure relief mechanisms, providing an extra layer of protection against pressure spikes.

In addition to safety, the efficiency of air compressors is significantly influenced by their relief valve features. Enhanced response times in relief valves have shown to improve energy efficiency by up to 15%, as noted in the 2023 Energy Efficiency in Compressed Air Systems report. Furthermore, the integration of smart technology in relief valves allows for real-time monitoring and adjustments, helping operators maintain optimal pressure levels and prevent energy waste. These key features not only facilitate smoother operation but also contribute to reduced operational costs, making them increasingly desirable in both industrial and commercial applications.

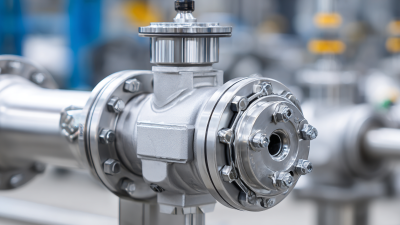

Common Types of Relief Valves Used in Air Compressors

Air compressors are essential tools in many industries, and the relief valve plays a critical role in their safety and efficiency. Various types of relief valves are utilized in these machines, each tailored to specific operational needs. One common type is the pop-off valve, which automatically releases excess pressure when it exceeds a predetermined limit. This type of valve ensures that the compressor operates within safe parameters, protecting both the machine and the user from potential hazards.

Another prevalent type is the adjustable relief valve, which allows the user to set the pressure threshold according to specific requirements. This flexibility makes it suitable for a variety of applications, from automotive repair shops to industrial production lines. Additionally, there are also fixed relief valves, which are pre-set to release pressure at a certain point and are perfect for applications where consistent pressure management is crucial. Understanding these different types of relief valves can help users select the right one for their air compressor, significantly enhancing the machine's performance and safety in the long run.

Understanding the Importance of Air Compressor Relief Valve in 2025 Top Models

Maintenance Tips for Air Compressor Relief Valves in 2025 Models

Proper maintenance of air compressor relief valves is essential for ensuring the optimal performance and longevity of your air compressor systems in 2025 models. These valves play a critical role in safety by preventing overpressure situations, which can lead to potential hazards. A well-maintained relief valve not only enhances safety but also improves the efficiency of the entire system.

One of the main tips for maintaining relief valves is to conduct regular visual inspections. Look for signs of corrosion, wear, or leaks around the valve and its fittings. It's advisable to check the valve's seating and ensure it opens and closes freely without any obstruction. Additionally, cleaning the valve periodically helps remove dirt and debris that can affect its performance, maintaining its reliability in high-pressure scenarios.

Another essential tip is to test the relief valve at least once a year. This involves applying pressure to ensure the valve opens at the designated set point and releases air as intended. If the valve does not function properly during testing, it may need to be replaced. Finally, always adhere to the manufacturer’s guidelines for specifications and maintenance intervals to ensure that every aspect of your air compressor system remains in peak condition.

Understanding the Importance of Air Compressor Relief Valve in 2025 Top Models - Maintenance Tips for Air Compressor Relief Valves in 2025 Models

| Model | Relief Valve Pressure (PSI) | Maintenance Frequency | Common Issues | Recommended Action |

|---|---|---|---|---|

| Model A | 125 | Every 6 months | Leakage, Sticking | Inspect and grease |

| Model B | 150 | Annually | Corrosion, Misalignment | Replace seals and check alignment |

| Model C | 100 | Every 3 months | Blockage, Pressure Fluctuation | Clean and test regularly |

| Model D | 130 | Every 4 months | Noise, Overheating | Check ventilation and replace valve if necessary |

Future Trends in Air Compressor Relief Valve Technology and Design

In 2025, the design and technology of air compressor relief valves are anticipated to experience significant advancements that will enhance their efficiency and reliability. Innovations are focusing on the integration of smart technologies, allowing for real-time monitoring and adjustment of pressure levels. These advancements will not only ensure optimal performance but also reduce the risk of system failures, which can be both costly and hazardous. The adoption of IoT (Internet of Things) capabilities in relief valves will allow operators to receive immediate alerts regarding pressure fluctuations, maintaining operational integrity and safety.

Another emerging trend is the emphasis on sustainability and eco-friendly materials in the manufacturing of relief valves. As industries become increasingly aware of their environmental impact, the push for using recyclable and non-toxic materials in valve construction is gaining momentum. This shift not only aligns with global sustainability goals but also enhances the durability and lifespan of these components. Furthermore, advancements in design are focusing on reducing the overall size and weight of relief valves without compromising functionality, making them more versatile for a variety of applications. These trends underline the critical role of relief valves in modern air compressor systems, ensuring they keep pace with the evolving demands of industrial applications.

Related Posts

-

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications

-

Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications

-

How to Choose the Best Safety Relief Valve for Your Application

-

The Essential Role of Vacuum Relief Valves in Ensuring Safety and Efficiency in Industrial Systems

-

2025 Top 5 Safety Relief Valve Innovations You Should Know