Understanding Hydraulic Relief Valves: Essential Insights for Efficient Fluid Control Systems

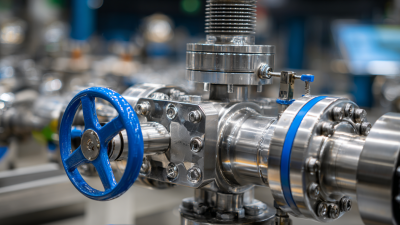

In the intricate world of fluid control systems, the hydraulic relief valve plays a pivotal role in maintaining optimal performance and safety. Understanding how these valves function is essential for engineers and technicians who design and maintain hydraulic systems. Hydraulic relief valves are designed to release excess pressure, preventing potential damage to machinery and ensuring efficient operation. By mastering the principles behind their operation and application, one can significantly enhance system reliability and longevity.

This article will explore key insights and practical tips to help you effectively integrate hydraulic relief valves into your fluid control systems, ultimately leading to improved efficiency and performance across various industrial applications. Whether you're a seasoned professional or a newcomer to the field, grasping these crucial aspects will empower you to make informed decisions in hydraulic system design and maintenance.

Hydraulic Relief Valve Basics: Key Functions and Applications in Fluid Control Systems

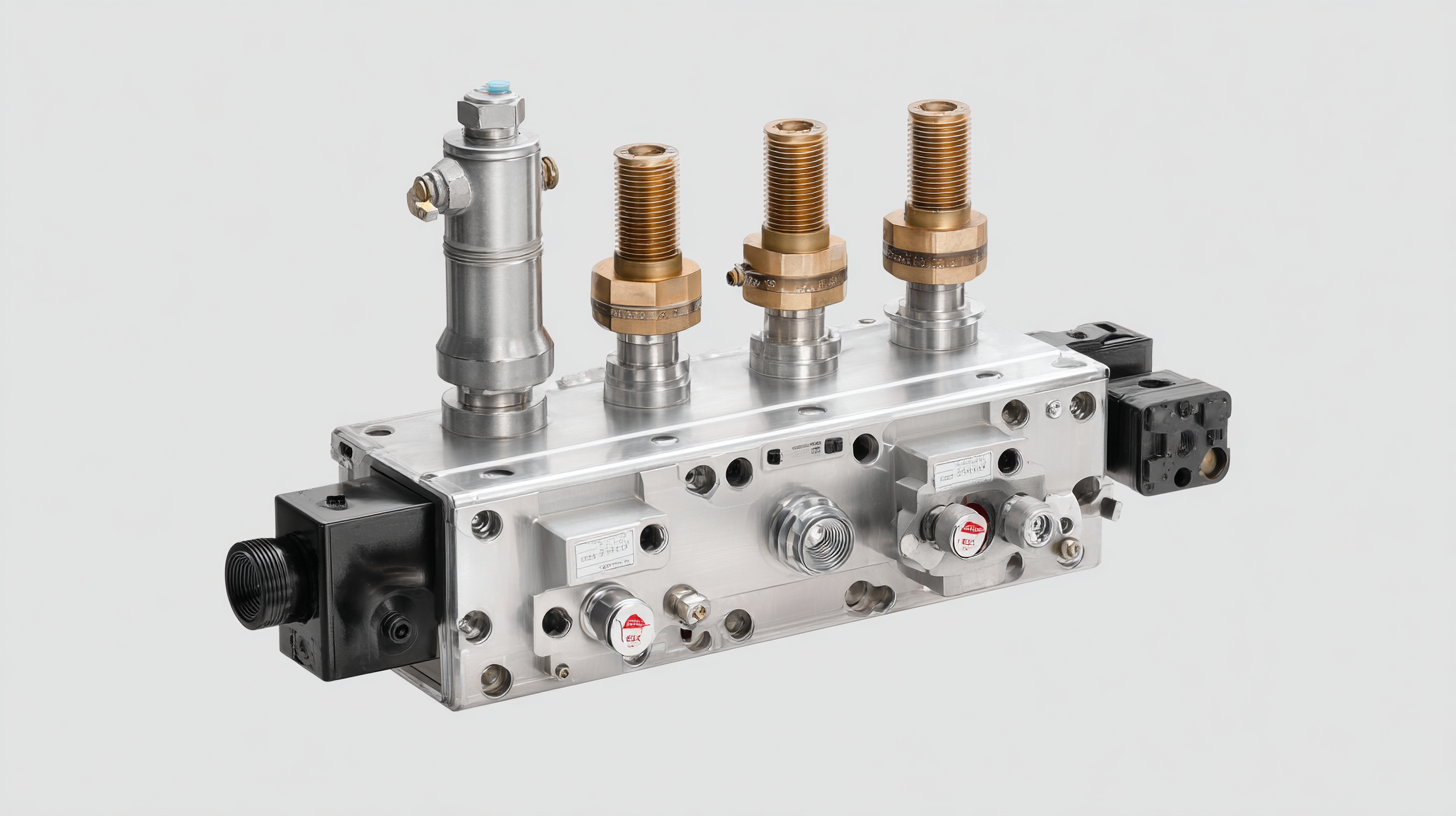

Hydraulic relief valves play a crucial role in fluid control systems by maintaining safe pressure levels and protecting hydraulic circuits from sudden surges. These valves work by allowing excess fluid to escape, thus preventing damage to pumps, hoses, and other components. When the hydraulic pressure exceeds a predetermined threshold, the relief valve opens, redirecting fluid back to the reservoir or to another part of the system. This functionality prevents pressure buildup that could result in catastrophic failures.

Hydraulic relief valves play a crucial role in fluid control systems by maintaining safe pressure levels and protecting hydraulic circuits from sudden surges. These valves work by allowing excess fluid to escape, thus preventing damage to pumps, hoses, and other components. When the hydraulic pressure exceeds a predetermined threshold, the relief valve opens, redirecting fluid back to the reservoir or to another part of the system. This functionality prevents pressure buildup that could result in catastrophic failures.

In various applications, ranging from industrial machinery to automotive hydraulics, the reliability of hydraulic relief valves is paramount. They are essential in ensuring that operators can maintain smooth and efficient system performance while safeguarding equipment. Understanding the key functions of these valves, such as pressure regulation and overload protection, can significantly enhance the effectiveness of fluid control systems. Proper selection and maintenance of hydraulic relief valves are crucial to achieving optimal performance and longevity in any hydraulic setup.

Critical Specifications: Understanding Pressure Ratings and Flow Capacities

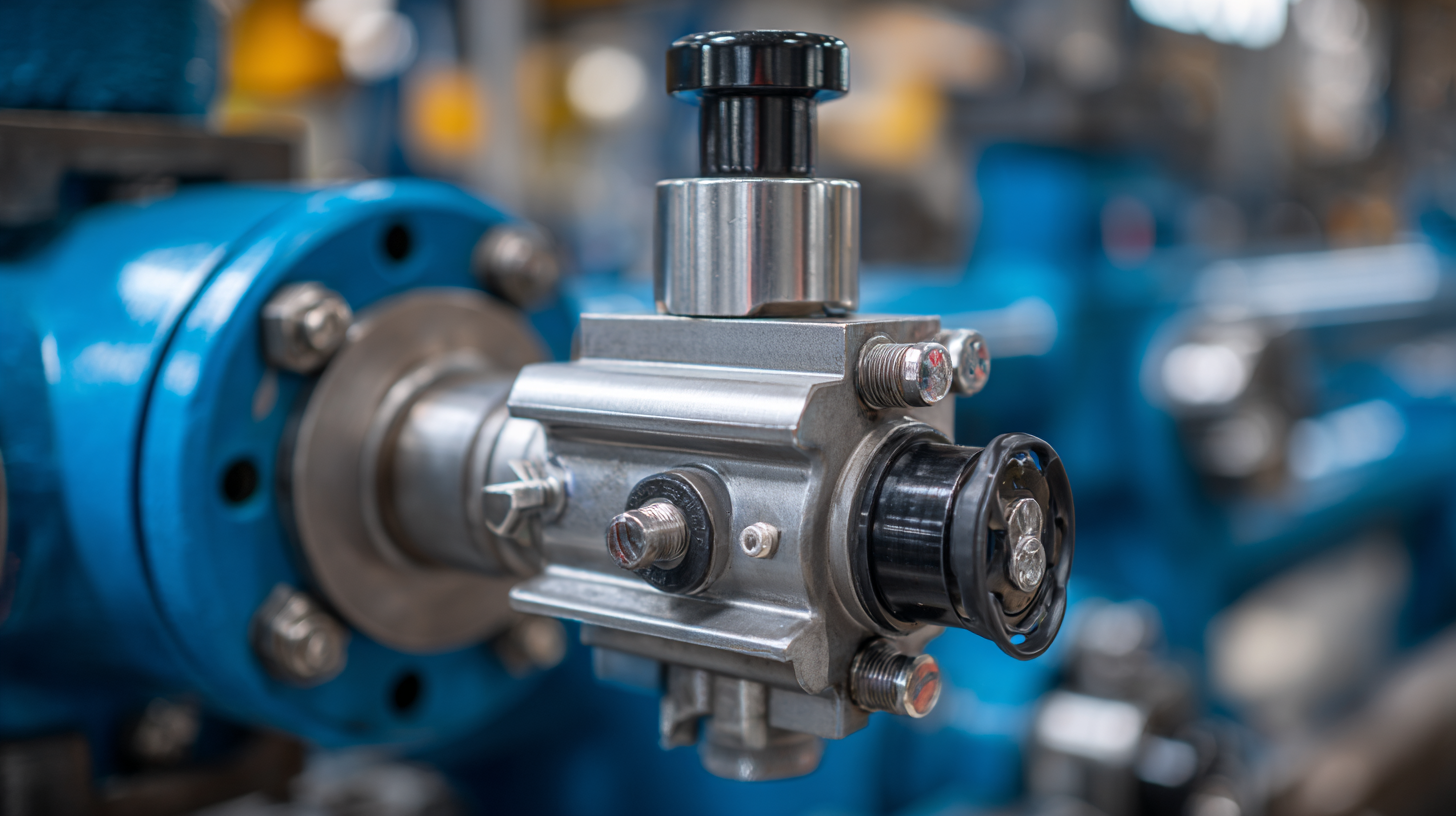

When it comes to selecting hydraulic relief valves, understanding pressure ratings and flow capacities is crucial for optimizing fluid control systems. Pressure ratings indicate the maximum pressure the valve can withstand during operation. Choosing a valve with a pressure rating that exceeds the system's highest operating pressure ensures safety and reliability. It is essential to consider both the static and dynamic pressure conditions that the valve may encounter, as fluctuations can lead to premature failure if not accounted for.

Flow capacity, measured in gallons per minute (GPM) or liters per minute (LPM), determines how much fluid can pass through the valve without excessive pressure drop. A valve with insufficient flow capacity can restrict fluid movement, adversely affecting system performance. Therefore, it’s important to match the flow capacity of the valve with the demands of the system. This involves understanding factors such as pipe size and length as well as the overall design of the hydraulic circuit.

Tip: Always consult manufacturer specifications to ensure the chosen valve aligns with your system's needs. Regularly review the system's performance and be prepared to adjust or replace valves as necessary to maintain optimal function. Monitoring pressure fluctuations can also help you identify potential issues before they escalate, ensuring a more efficient fluid control system.

Maintenance Tips: Prolonging Lifespan and Ensuring Reliability in Relief Valves

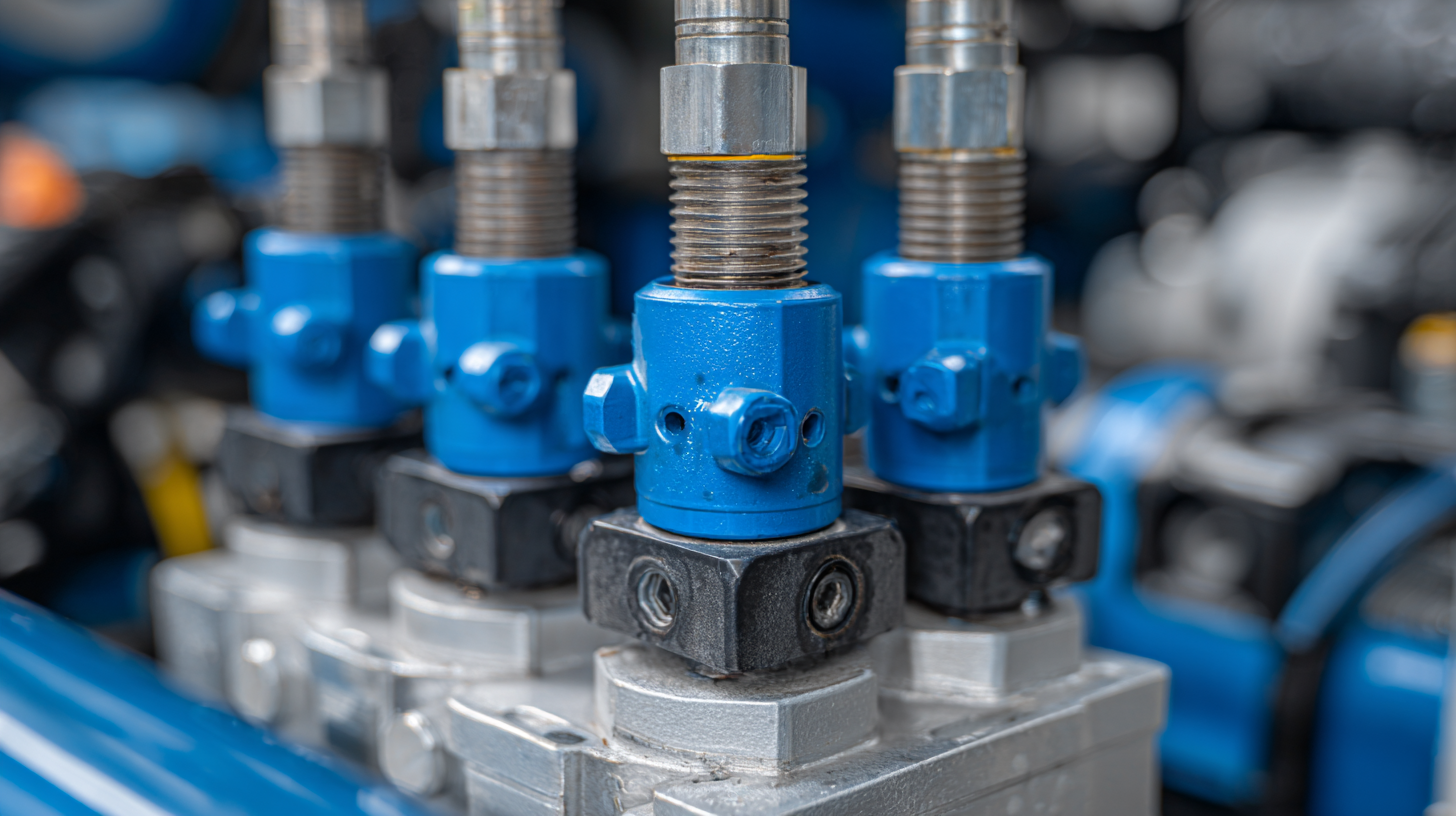

Proper maintenance of hydraulic relief valves is crucial for ensuring their longevity and reliability. Regular inspections are essential to identify any signs of wear or damage. Checking seals and fittings for leaks can prevent potential failures and maintain system efficiency. It is recommended to clean the valve regularly to remove any debris that may hinder its performance. Additionally, confirming that the relief valve is functioning correctly under various pressures is vital. Using a pressure gauge can help in monitoring performance, allowing for timely adjustments or replacements when necessary.

Another key maintenance tip involves lubrication. Although many hydraulic relief valves are designed to operate with minimal lubrication, applying the right lubricant can enhance their functionality and reduce friction. Always refer to the manufacturer’s guidelines for specific lubrication requirements. Furthermore, maintaining the surrounding environment clean and free of contaminants can greatly extend the lifespan of these valves. By following these maintenance practices, operators can ensure their hydraulic relief valves remain reliable components in fluid control systems, effectively mitigating pressure surges and protecting equipment.

Understanding Hydraulic Relief Valves: Essential Insights for Efficient Fluid Control Systems

| Dimension | Specification | Maintenance Tips | Lifespan Expectancy | Common Issues |

|---|---|---|---|---|

| Pressure Range | 5 to 100 psi | Regularly check for proper sealing. | 5-10 years | Leakage and pressure spikes |

| Material | Stainless Steel | Lubricate moving parts annually. | 10-15 years | Corrosion and rust formation |

| Flow Rate | 10 to 100 GPM | Inspect filter screens quarterly. | 8-12 years | Blockages and flow restrictions |

| Temperature Range | -30 to 250 °F | Check for temperature-induced wear. | 5-10 years | Seal degradation |

Impact of Temperature Variations: Material Selection for Optimal Performance

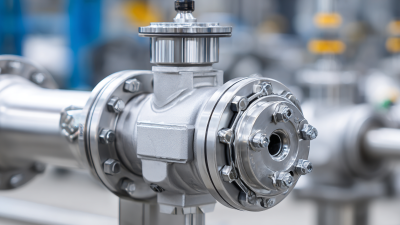

Temperature variations play a crucial role in the performance and reliability of hydraulic relief valves, making material selection a pivotal consideration for efficient fluid control systems. As temperature fluctuates, the mechanical properties of materials can change significantly, affecting the valve's performance under pressure. Recent studies highlight the importance of selecting materials that maintain durability and function even at extreme temperatures. A comprehensive analysis suggests that the failure of hydraulic components often correlates with inadequate thermal management, emphasizing the need for advanced materials capable of withstanding elevated temperatures without compromising their integrity.

Tips: When selecting materials for hydraulic relief valves, consider those with high thermal stability and resistance to thermal cycling. For instance, alloys and composites that exhibit minimal thermal expansion can provide greater reliability in fluid control systems. Additionally, it's advisable to conduct performance assessments under varying temperature conditions to ensure optimal operation and longevity.

Moreover, it is essential to recognize that the right material choice can enhance not only the durability of the valve but also its efficiency. The latest material selection indicators have been designed to aid engineers in choosing options that outperform traditional materials in both strength and thermal resistance. By focusing on temperature-dependent characteristics, companies can achieve extended service lifespans for their hydraulic systems, ultimately leading to greater cost-effectiveness and safety in operations.

Efficiency Metrics: Evaluating the Effectiveness of Hydraulic Relief Valves in Systems

Hydraulic relief valves are critical components in fluid control systems, ensuring safety and efficiency by preventing system overpressure. Evaluating their effectiveness requires a deep dive into efficiency metrics, particularly pressure drop, flow capacity, and response times. According to the Fluid Power Journal, optimal relief valve performance can reduce energy consumption in hydraulic systems by approximately 15-25%, demonstrating their significance in cost-effective fluid control.

Hydraulic relief valves are critical components in fluid control systems, ensuring safety and efficiency by preventing system overpressure. Evaluating their effectiveness requires a deep dive into efficiency metrics, particularly pressure drop, flow capacity, and response times. According to the Fluid Power Journal, optimal relief valve performance can reduce energy consumption in hydraulic systems by approximately 15-25%, demonstrating their significance in cost-effective fluid control.

Moreover, manufacturers often provide data highlighting the relationship between valve sizing and performance. For instance, a study published in the Journal of Hydraulic Engineering indicates that improperly sized relief valves can lead to a flow capacity decrease of up to 30%, compromising system effectiveness. An additional report by the International Fluid Power Society emphasizes that a quick response time, typically under 100 milliseconds, is essential for maintaining system integrity and performance under dynamic loads. These metrics not only help in selecting appropriate devices but also assist in predictive maintenance strategies, ultimately leading to enhanced operational longevity and reduced downtime.

Related Posts

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications

-

The Essential Role of Vacuum Relief Valves in Ensuring Safety and Efficiency in Industrial Systems

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

-

Unlocking Efficiency: The Role of Consolidated Valves in Modern Industrial Applications

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Understanding the Importance of Relief Valves in Industrial Applications