Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications

In the realm of industrial applications, optimizing machinery performance is critical to ensuring operational efficiency and safety. Central to this optimization is the hydraulic relief valve, a key component that protects hydraulic systems from excessive pressure. Understanding the performance metrics of hydraulic relief valves is essential for engineers and technicians alike, as it directly influences system reliability and longevity. This comprehensive guide aims to unlock the hidden efficiencies within hydraulic relief valve performance, offering valuable insights and practical tips to enhance their functionality. By delving into the crucial parameters that define the performance of these valves, we empower professionals to make informed decisions, reduce downtime, and ultimately achieve a more streamlined operational process. Join us as we explore the essentials of hydraulic relief valve performance metrics and how they can significantly impact your industrial applications.

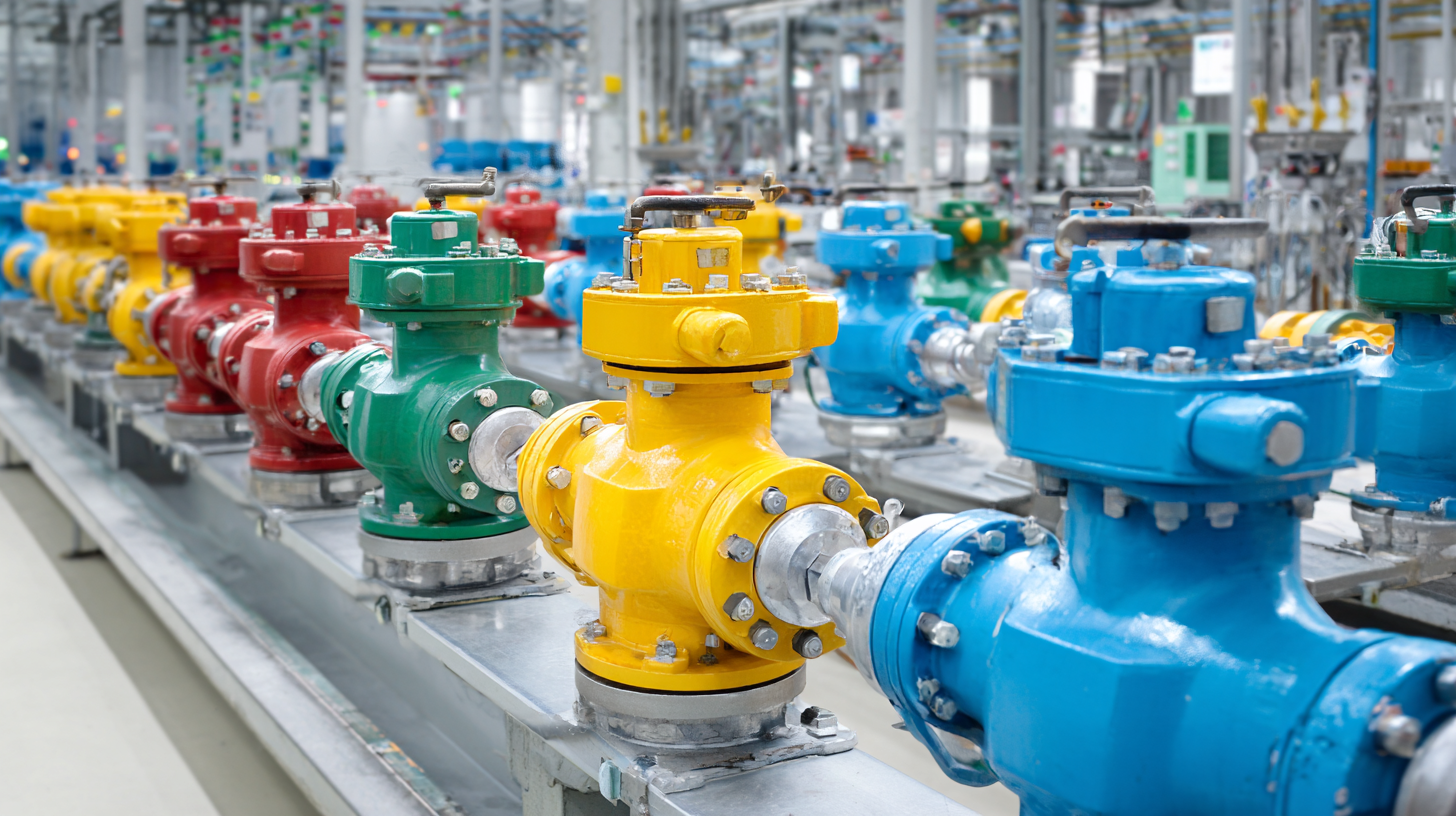

Understanding the Basics of Hydraulic Relief Valve Functionality in Industrial Systems

Hydraulic relief valves play a crucial role in the safety and efficiency of industrial systems. Their primary function is to manage excess pressure within hydraulic circuits, preventing potential damage to machinery and components. When the system pressure exceeds a predetermined threshold, the relief valve opens, allowing fluid to escape and thereby reducing pressure to safe levels. This functionality is essential for maintaining the integrity of hydraulic systems, which rely on precise pressure regulation for optimal operation.

In addition to safeguarding equipment, hydraulic relief valves contribute to system efficiency. By ensuring that pressure levels remain within designated limits, these valves minimize energy waste and enhance performance. Understanding the performance metrics of hydraulic relief valves—such as response time, flow capacity, and pressure settings—is vital for engineers and operators. These metrics inform maintenance schedules and facilitate timely interventions, ensuring that the hydraulic system operates smoothly under varying loads and conditions.

Identifying Key Performance Metrics for Optimal Valve Efficiency

In the realm of industrial applications, maximizing the efficiency of hydraulic relief valves is essential for optimizing overall system performance. Key performance metrics for these valves include flow rates, pressure settings, and response times. According to recent studies, system efficiency can be significantly enhanced through the use of precision control valves that adapt to fluctuating operational conditions. In power generation facilities, for instance, innovative approaches to fluid management have led to notable improvements in efficiency, with modern pumping systems contributing to energy savings of up to 30%.

Advanced analytics, particularly machine learning techniques, are becoming crucial in identifying optimal performance metrics for hydraulic relief valves. These technologies facilitate accurate predictions of operational parameters, assisting engineers in making informed decisions that drive efficiency. The implementation of multi-objective optimization strategies further allows for the fine-tuning of valve operations, balancing factors such as hydraulic stability and energy conservation. Reports suggest that employing such approaches can reduce operational costs significantly while enhancing safety and reliability in industrial fluid systems.

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications

| Performance Metric | Description | Typical Value | Units |

|---|---|---|---|

| Cracking Pressure | The pressure at which the valve begins to open | 2000 | psi |

| Flow Rate | The volume of fluid that passes through the valve per unit time | 50 | gpm |

| Response Time | Time taken for the valve to respond to pressure changes | 0.5 | sec |

| Leakage Rate | The amount of fluid that leaks through the valve when it is closed | 0.1 | gpm |

| Temperature Range | The acceptable temperature range for the valve operation | -20 to 220 | °F |

Analyzing Pressure Regulation and Response Times in Relief Valve Operations

In industrial applications, the performance of hydraulic relief valves is critical for maintaining optimal system pressure and ensuring safety. Analyzing pressure regulation involves understanding how effectively a valve can respond to fluctuations in pressure. Response times are essential metrics; they indicate how quickly a relief valve can react to overpressure conditions, which is vital for preventing system failures or accidents.

Tips for improving pressure regulation include regular maintenance and calibration of relief valves to ensure they respond accurately under varying conditions. Additionally, operators should monitor pressure variance constantly to identify potential delays in response time. This proactive approach helps maintain system integrity and efficiency.

Tips for improving pressure regulation include regular maintenance and calibration of relief valves to ensure they respond accurately under varying conditions. Additionally, operators should monitor pressure variance constantly to identify potential delays in response time. This proactive approach helps maintain system integrity and efficiency.

Another crucial aspect to consider in relief valve operations is selecting the appropriate valve size and type for specific applications. A valve that is too small may not relieve pressure effectively, while one that is too large could introduce unnecessary delays. Understanding the specific requirements of your hydraulic system will enhance overall performance and safety.

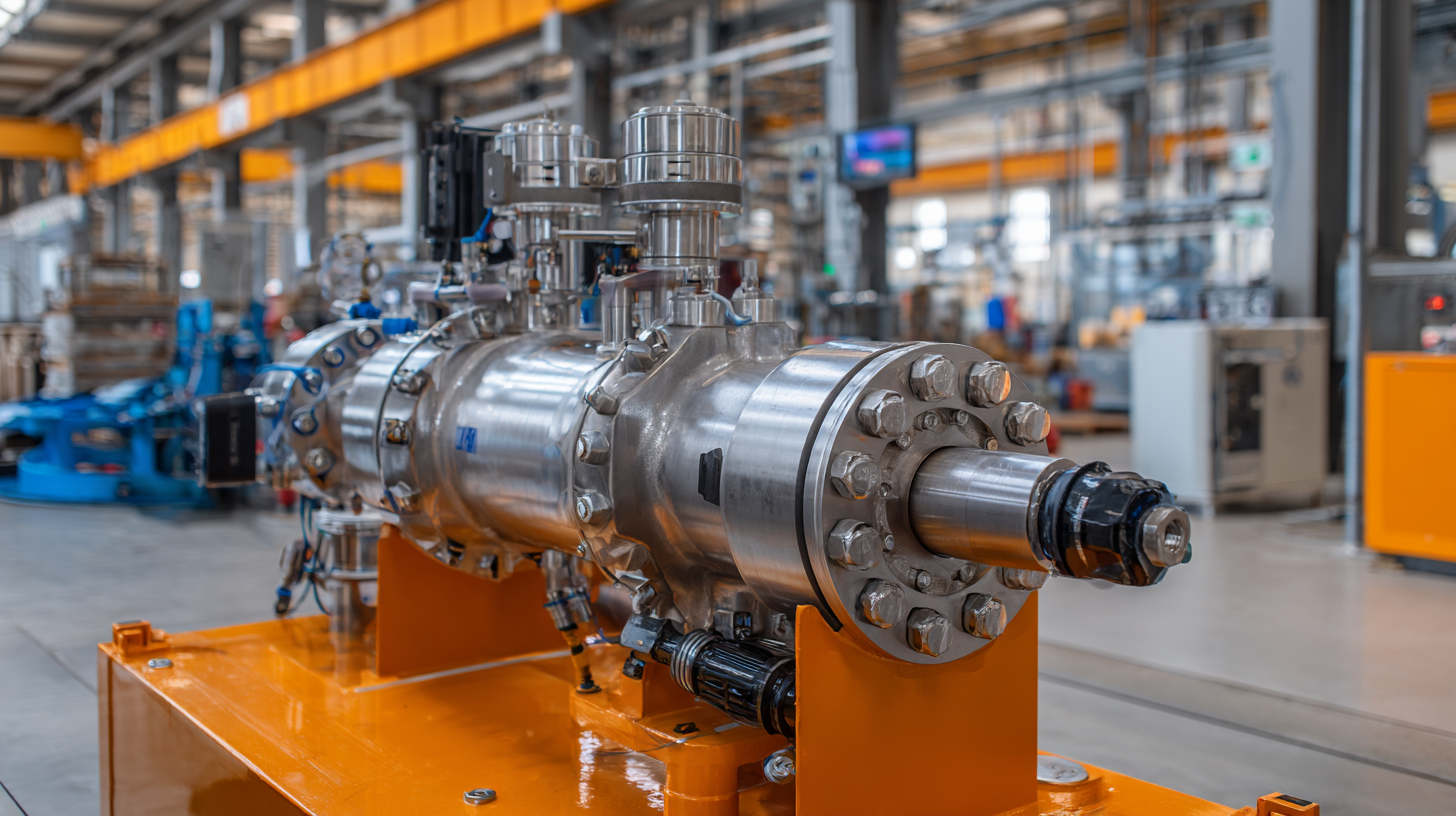

Assessing the Impact of Valve Sizing and Selection on System Performance

The performance of hydraulic relief valves is critical in ensuring efficient operation in industrial applications. An essential aspect of this performance is the valve sizing and selection process. Properly sized relief valves prevent system overloads by allowing excess pressure to be released, thereby protecting both the hydraulic components and the machinery involved. If a valve is too small, it may not open in time to prevent damage, leading to catastrophic failures. Conversely, an oversized valve can lead to unnecessary cycling, resulting in increased wear and inefficiency.

Selecting the right valve involves analyzing various factors, including system pressure, flow rate, and fluid characteristics. Engineers must consider whether the application requires a conventional, pilot-operated, or direct-acting relief valve, all of which exhibit different performance metrics. Additionally, attention to materials and design features is crucial, as these factors can impact the valve's responsiveness and reliability in different operating conditions. Ultimately, meticulous valve sizing and selection serve to optimize system performance, enhance safety, and extend the operational lifespan of hydraulic systems in industrial settings.

Hydraulic Relief Valve Performance Metrics

This chart illustrates key performance metrics for hydraulic relief valves, highlighting the impact of valve sizing and selection on overall system performance. The valve size selected here is 2 inches, with a flow rate of 150 GPM, a pressure drop of 30 PSI, and a response time of 0.5 seconds.

Implementing Testing Procedures to Measure Relief Valve Effectiveness and Reliability

When it comes to hydraulic relief valves, measuring effectiveness and reliability is crucial for ensuring optimal performance in industrial applications. Implementing robust testing procedures can help identify potential issues before they cause significant downtime or equipment failure. According to a report by the International Journal of Fluid Power, nearly 20% of hydraulic system failures are attributable to improperly functioning relief valves, highlighting the need for rigorous evaluation.

To effectively measure relief valve performance, operators should conduct regular pressure and flow testing, ensuring that the valve opens at its designated set point and responds accurately to system demands. Utilizing modern diagnostic tools, such as pressure transducers and flow meters, can provide precise readings and aid in identifying inconsistencies.

Tips: Regular maintenance checks and adherence to manufacturer specifications can enhance the reliability of hydraulic relief valves. Implementing a comprehensive testing routine not only improves equipment longevity but also minimizes operational risks. Additionally, training personnel on proper testing techniques can significantly enhance the effectiveness of these procedures.