What is a hydraulic relief valve and how does it work?

A hydraulic relief valve is a crucial component in fluid systems. It ensures that pressure does not exceed safe limits, protecting equipment from damage. According to a recent industry report by the Hydraulic Institute, improper pressure management accounts for over 30% of hydraulic system failures. This statistic underscores the importance of a reliable hydraulic relief valve.

In operation, a hydraulic relief valve regulates the pressure within hydraulic circuits. When pressure reaches a set point, the valve opens, allowing excess fluid to escape. This action protects hydraulic components from catastrophic failure. Many engineers today recognize that without a properly functioning hydraulic relief valve, the entire system's efficiency is compromised.

However, it is essential to note that not all hydraulic relief valves are created equal. Factors such as wear, incorrect settings, or inadequate maintenance can render them ineffective. A poorly chosen or maintained valve may not open when needed, leading to increased pressure and potential failure. Reflecting on this, industry professionals must prioritize the selection and upkeep of these vital components.

What is a Hydraulic Relief Valve?

A hydraulic relief valve is a crucial component in hydraulic systems. It controls excess pressure. When the system pressure exceeds a preset limit, the valve opens. This allows fluid to escape. It prevents damage to pumps and other system components.

Understanding how this valve works can help in maintenance. Sometimes, the valve might stick or fail to open. This can cause pressure buildup, leading to system failure. Regular checks are essential. Inspect for dirt or wear. Maintaining clean fluids can greatly extend the valve's lifespan.

**Tip:** Always keep the relief valve accessible. Regularly monitor the pressure readings. This can prevent unexpected issues. If you notice fluctuating pressure, it might be time to inspect the valve.

The operation of a hydraulic relief valve is influenced by several factors. Temperature and fluid viscosity play a role. Changes in these conditions can affect how the valve performs. Keep this in mind during seasonal shifts. Regular maintenance is vital for optimal performance.

What is a hydraulic relief valve and how does it work?

| Component | Function | Applications | Pressure Settings |

|---|---|---|---|

| Spring | Provides resistance against fluid pressure | Control systems in machinery | Varies, typically 50 to 300 psi |

| Piston | Moves to open or close the valve | Automotive hydraulic systems | Varies based on application |

| Port | Allow fluid to pass through and vent | Industrial hydraulic circuits | Usually set between 100 to 500 psi |

| Actuator | Controls the operation of the valve | Robotics and automated systems | Customizable to system needs |

The Basic Components of a Hydraulic Relief Valve

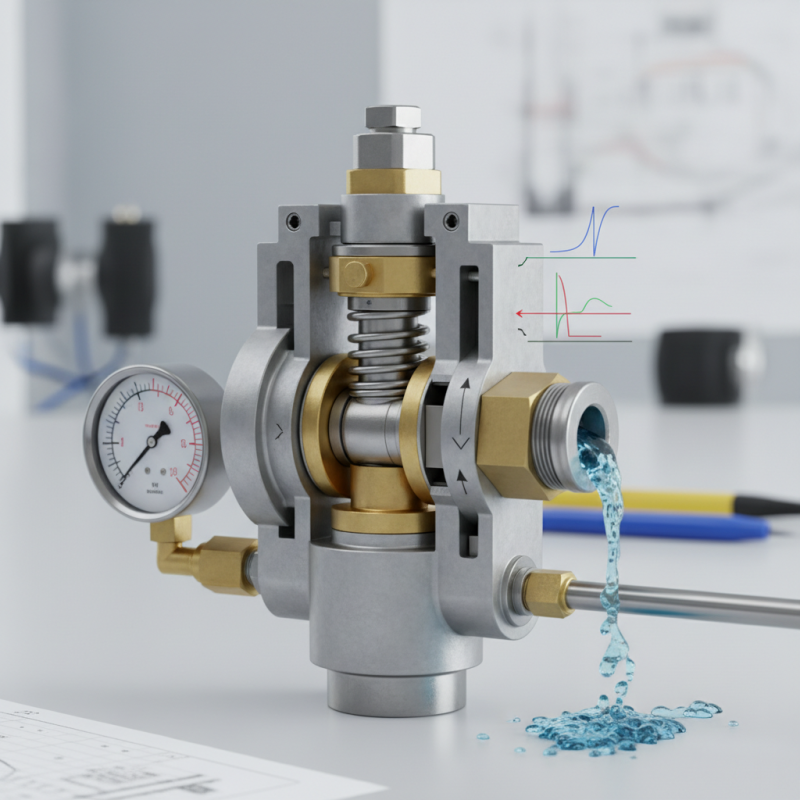

A hydraulic relief valve is essential in hydraulic systems. It regulates pressure, protecting components from damage. Understanding its basic components reveals how it functions effectively.

The valve consists mainly of a spring, a piston, and a housing. The spring provides the necessary force to hold the piston in place. When system pressure exceeds a set limit, the piston moves. This action opens a port, allowing excess fluid to escape. This process prevents dangerous pressure buildup, which could cause equipment failure. According to industry studies, around 30% of hydraulic failures stem from pressure issues. Properly functioning relief valves can significantly reduce this risk.

In addition, the valve's adjustment mechanism is crucial. Users often overlook the importance of calibration. Misaligned settings can lead to inadequate pressure relief or unnecessary fluid loss. Reports indicate that about 15% of hydraulic systems experience recurrent issues due to improper adjustments. Addressing these concerns can enhance system reliability and performance. Recognizing the importance of each component aids in maintaining optimal hydraulic function.

How Hydraulic Relief Valves Function in a System

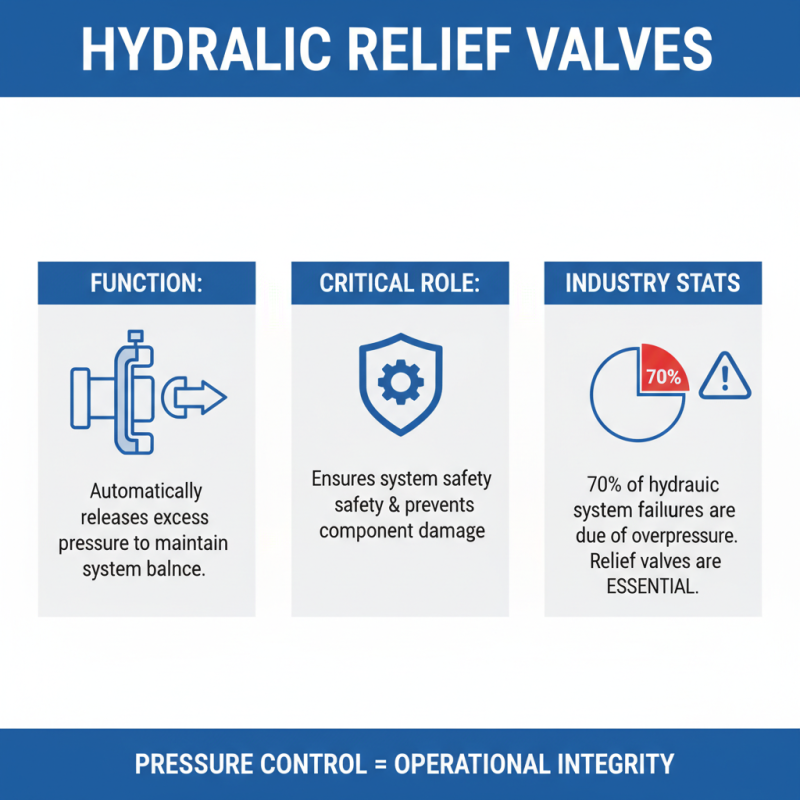

Hydraulic relief valves play a crucial role in various systems by maintaining pressure and ensuring safety. These components function by automatically releasing excess pressure, preventing system failures. According to industry reports, pressure control is critical in hydraulic systems, as 70% of failures arise from overpressure scenarios. This makes relief valves essential for operational integrity.

In a hydraulic system, a relief valve opens at a predetermined pressure. The pressure on the inlet side forces the valve seat to lift, allowing fluid to escape to the reservoir. This action limits pressure buildup, protecting hydraulic components from damage. Systems lacking proper relief valves may experience catastrophic failures or reduced performance. Reports show that inadequate pressure regulation can reduce a system's lifespan by up to 30%.

However, choosing the right relief valve can be challenging. It requires careful consideration of pressure ratings and flow capabilities. An incorrectly sized valve can either lead to insufficient pressure relief or excessive leakage. Professionals often overlook these details. The importance of precise calibration cannot be overstated. Many systems operate with margins that are too narrow, leading to dangerous situations. Understanding the dynamics of hydraulic relief valves is essential for achieving reliability and safety in hydraulic applications.

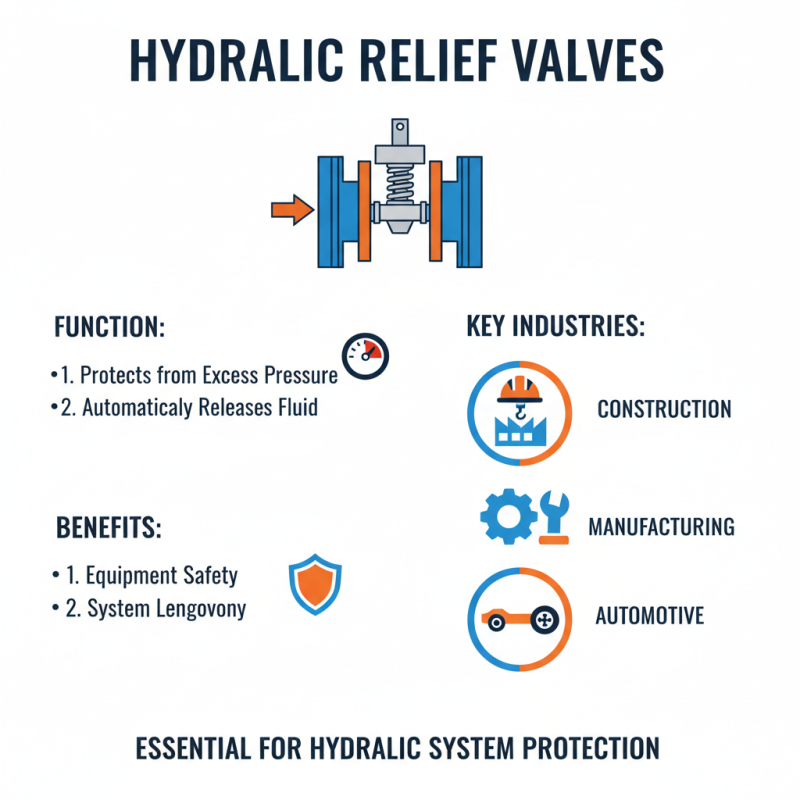

Applications of Hydraulic Relief Valves in Industry

Hydraulic relief valves are essential components in various industrial applications. They protect hydraulic systems from excess pressure. These valves automatically release fluid when the pressure exceeds a predetermined level, ensuring equipment and safety. Industries such as construction, manufacturing, and automotive rely heavily on these valves.

Applications in construction are abundant. Hydraulic relief valves are used in excavators and cranes. A study in 2022 reported that construction machinery utilizes these valves to prevent failures. Efficient operation is critical, especially under high loads. A malfunction could lead to costly downtime and accidents.

In manufacturing, hydraulic systems control presses, molds, and assembly lines. Studies indicate that the global hydraulic valve market reached approximately $26.85 billion in 2021. This number reflects the importance of reliable pressure management. Inadequate pressure relief can disrupt production and lead to safety hazards. Maintenance is vital to avoid system failures.

Tip: Regularly inspect relief valves to prevent operational issues. A small oversight can lead to significant consequences. Understanding the specific pressure limits of your equipment is crucial. Always consult technical documents for accurate settings and replacements.

Maintenance and Troubleshooting of Hydraulic Relief Valves

Hydraulic relief valves play a critical role in controlling pressure in hydraulic systems. Regular maintenance is essential to ensure they function effectively. One common issue is contamination. Dirt and debris can clog the valve, leading to erratic performance. Regularly inspect the valve and clean or replace filters to minimize this risk.

Another area to focus on is the valve's response time. A slow response can be indicative of internal wear. Check for leaks around the valve body. This may indicate that internal seals need replacement. Failure to address these issues can result in system failure, causing downtime and costly repairs.

Monitoring the pressure settings is also vital. Incorrect settings can lead to hydraulic overpressure or inefficient operation. Take the time to calibrate the valve regularly. However, even with routine checks, problems can still arise unexpectedly. Consider keeping a record of any changes in performance for future reference. This habit can reveal patterns, aiding in troubleshooting efforts.

Hydraulic Relief Valve Performance Analysis

This bar chart illustrates the performance of a hydraulic relief valve under operational conditions, comparing the set pressure, actual pressure, pressure drop, and flow rate.

Related Posts

-

2025 Top 10 Hydraulic Relief Valves: Your Ultimate Guide to Selection

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Understanding Hydraulic Relief Valves: Essential Insights for Efficient Fluid Control Systems

-

2025 Top 5 Safety Relief Valve Innovations You Should Know

-

Best Watts Pressure Relief Valve Options for Optimal Safety and Efficiency