10 Essential Tips for Choosing the Right Vacuum Relief Valve

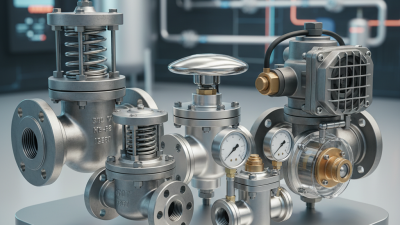

When selecting a vacuum relief valve, several factors come into play. A vacuum relief valve is crucial for maintaining system integrity. It prevents vacuum conditions that can lead to equipment failure. Without the right valve, costly mistakes can happen. Choosing poorly may result in leaks or ruptures.

Consider the materials used in the valve. They should match the system's requirements. A mismatch can cause rapid wear or even failure. Look for valves designed for specific applications. Generic options may not hold up under pressure.

Size is another important aspect. An incorrectly sized vacuum relief valve can disrupt performance. It could either allow too much air in or not enough. This imbalance can lead to erosion of systems and unwanted downtime. Make your choice carefully. While it may seem straightforward, selecting the right vacuum relief valve requires thought and attention.

Understanding the Functionality of Vacuum Relief Valves

Vacuum relief valves play a crucial role in maintaining system pressure. They prevent vacuum formation, which can lead to collapse of containers or piping. These valves ensure that air enters the system at specific pressures, protecting equipment from damage. Understanding their functionality is vital for efficient operations.

Choosing the right vacuum relief valve involves several considerations. Material compatibility is essential; ensure the valve suits your system’s medium. Additionally, valve size directly impacts performance. A valve that is too small may not react quickly enough. On the other hand, one that is oversized can lead to inefficiencies.

Installation location is another vital factor. The valve should be placed where it can best respond to pressure changes. Monitoring and maintenance also cannot be overlooked. Regular checks can highlight any malfunctions. Addressing these issues promptly can save costs and prevent operational downtime, leading to improved reliability.

10 Essential Tips for Choosing the Right Vacuum Relief Valve

| Tip Number | Tip Description | Key Considerations | Application Context |

|---|---|---|---|

| 1 | Understand the Pressure Range | Choose a valve that suits your specific pressure needs. | Industrial piping systems |

| 2 | Consider Material Compatibility | Ensure materials used in the valve are compatible with the substances involved. | Chemical processes |

| 3 | Evaluate Flow Capacity | Select a valve that can handle the necessary flow rates. | HVAC systems |

| 4 | Check for Operational Reliability | Choose valves known for durability and consistent performance. | Food and beverage industry |

| 5 | Installation Requirements | Consider ease of installation and any specific requirements. | Water treatment systems |

| 6 | Maintenance Needs | Evaluate how often the valve will need servicing and its maintenance accessibility. | Manufacturing machinery |

| 7 | Size Appropriateness | Select a valve size that fits the piping system precisely. | Pipeline installations |

| 8 | Cost Effectiveness | Consider not just the purchase price, but overall cost efficiency. | Budget constrained projects |

| 9 | Manufacturer Reliability | Research the manufacturer's reputation and product reviews. | All applications |

| 10 | Seek Professional Advice | Consult with experts for customized solutions to specific needs. | Complex systems |

Factors to Consider When Selecting a Vacuum Relief Valve

When selecting a vacuum relief valve, several key factors must be considered to ensure optimal performance. The valve should match the specific application requirements. A recent industry report highlights that improper valve selection can lead to a 20% efficiency loss in system operations. This emphasizes the need for accurate sizing and compatibility with the existing system pressures.

Material choice is critical. The valve must withstand the chemical conditions it will encounter. Failure to choose the right material can lead to premature failure. According to a study by the Fluid Power Association, almost 30% of valve failures result from material incompatibility. Additionally, investigating installation and maintenance ease is often overlooked. Complicated setups can result in higher long-term costs and increase downtime.

Another significant consideration is the valve response time. The ideal valve should operate quickly to maintain system stability. Delays in response can compromise safety and result in system damage. Research indicates that even a one-second delay can lead to a severe pressure drop, causing additional risks. User feedback often reveals dissatisfaction with valve responsiveness, highlighting a need for industry reflection on design improvement.

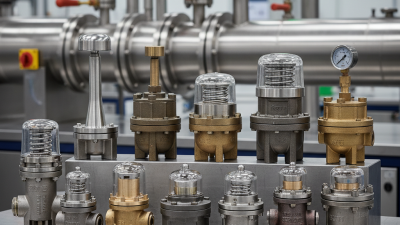

Material and Design Considerations for Durability and Efficiency

When selecting a vacuum relief valve, the materials used are crucial. Stainless steel is often preferred. It offers strength, corrosion resistance, and durability. However, it can be more expensive. Plastic valves are lightweight and cost-effective. But, they may not withstand extreme temperatures. You must weigh the pros and cons of each material. Consider the specific application and environment where the valve will be used.

Design is another key factor in ensuring efficiency. A well-designed valve minimizes pressure fluctuations. Look for models that allow for smooth airflow. Features like internal springs and seals matter. They affect the valve's response time and effectiveness. However, a more complex design might complicate maintenance. Simplicity can lead to fewer failures. Reflect on how often maintenance will occur.

Lastly, don’t overlook the manufacturer’s specifications. Always check if materials meet industry standards. It’s a way to ensure long-term performance. Balancing durability and efficiency is not easy. Sometimes, compromises are necessary. Make informed decisions based on your needs. This approach will ultimately lead to better outcomes.

Durability and Efficiency of Vacuum Relief Valves: Material and Design Considerations

Common Applications of Vacuum Relief Valves in Various Industries

Vacuum relief valves play a critical role across multiple industries. In the food and beverage sector, they help prevent vacuum conditions that can lead to collapse in containers. According to a 2022 industry report, improper vacuum management can cause spoilage and loss of product integrity. It is essential to choose valves that can handle both pressure and sub-atmospheric conditions effectively.

In pharmaceuticals, vacuum relief valves maintain the right environment during manufacturing processes. A study released by a leading safety organization indicated that 70% of product failures stem from poor pressure controls. This raises questions about the quality standards currently practiced. Many facilities still overlook the importance of proper valve selection. Their oversight can lead to contamination and occasional production halts.

Chemical industries also rely heavily on vacuum relief valves. These valves protect storage tanks from implosion, especially during rapid temperature changes. A report suggested that failures in this area can result in severe safety hazards. Yet, despite these warnings, outdated equipment remains common. Industries must address these shortcomings to enhance safety and efficiency.

Maintenance Tips for Ensuring Optimal Performance of Vacuum Relief Valves

Maintaining vacuum relief valves is crucial for optimal performance. Regular inspection is vital. It minimizes the risk of failures in operation. Research indicates that up to 30% of vacuum system issues stem from valve malfunctions. Ensuring these valves function correctly can significantly extend the lifespan of your equipment.

Check for leaks periodically. A small leak can cause a large pressure imbalance. Data shows that even minor leaks can reduce efficiency by 15%. Use ultrasonic leak detectors for precision. This method is reliable and helps identify leakage points without disrupting the system. Regular cleaning is also important. Dirt and debris can damage seals, leading to reduced effectiveness.

Documenting maintenance activities is essential. Accurate logs help track performance trends. If issues arise, reviewing these logs can clarify the history. This documentation aids in identifying patterns over time. Neglect may lead to unexpected downtime, impacting productivity. Professional assessments may be required periodically. These steps can improve both safety and efficiency.

Related Posts

-

Top 10 Vacuum Relief Valves for Optimal Pressure Management in Industrial Applications

-

Understanding Vacuum Relief Valves for 2025 Top Applications and Benefits

-

Essential Tips for Understanding Vacuum Relief Valve Functionality and Maintenance

-

Top 10 Common Questions About Boiler Relief Valves Answered

-

Top 5 Pressure Vacuum Relief Valves: Maximizing Safety and Efficiency

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System