Top 10 Common Questions About Boiler Relief Valves Answered

In the world of boiler systems, understanding the intricacies of a boiler relief valve is crucial for safe and efficient operation. As John Smith, a leading expert in thermal engineering, once stated, “A properly functioning boiler relief valve is the first line of defense against excessive pressure, ensuring the safety and longevity of your boiler system.” With this in mind, we delve into the top 10 common questions about boiler relief valves, addressing concerns that many professionals and homeowners alike may have.

Boiler relief valves play a pivotal role in preventing catastrophic failures by releasing excess pressure that can build up within a boiler. Understanding their function, maintenance, and installation is essential for anyone involved in the management of boiler systems. In this article, we aim to clarify common uncertainties surrounding boiler relief valves, ensuring that readers are well-informed to make effective decisions regarding their maintenance and operation. From operational mechanics to troubleshooting, our goal is to empower you with the knowledge necessary to navigate the complexities of boiler safety.

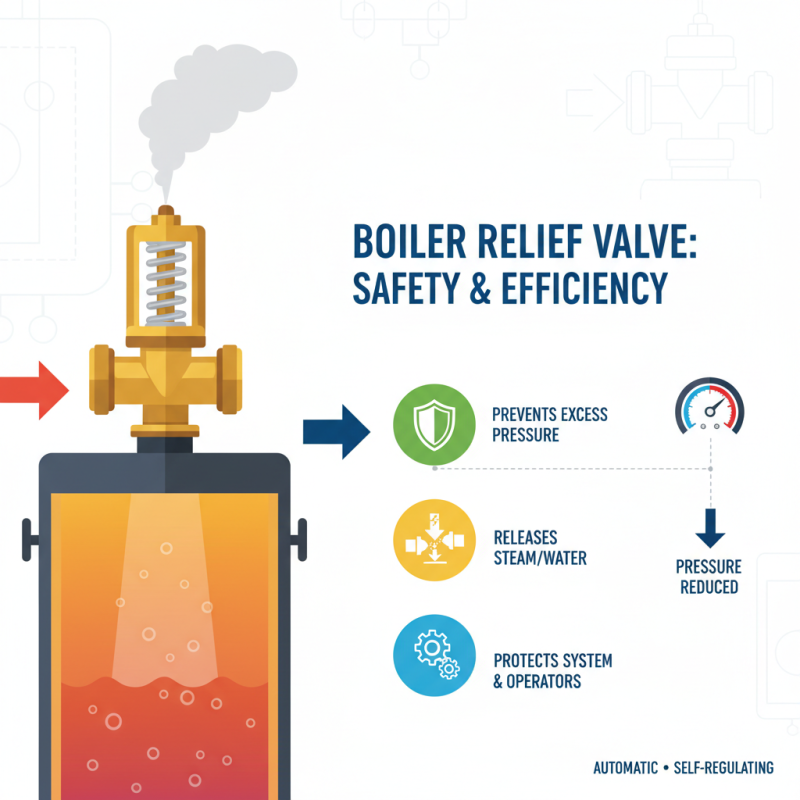

What Are Boiler Relief Valves and Their Purpose?

Boiler relief valves play a critical role in maintaining the safety and efficiency of a boiler system. These valves are designed to prevent excessive pressure buildup by releasing steam or water when pressure reaches a predetermined limit. Essentially, they serve as a safety mechanism, ensuring that the boiler operates within safe pressure ranges and reducing the risk of dangerous malfunctions or catastrophic failures.

When selecting and installing boiler relief valves, it’s important to consider the pressure ratings and compatibility with the specific boiler type. Regular maintenance checks are essential to ensure that these valves function properly. In addition, operators should familiarize themselves with local codes and regulations related to boiler safety to ensure compliance and optimal performance.

Tips: Always conduct routine inspections of relief valves to check for any signs of wear or malfunction. Ensure that the discharge piping from the valve is directed away from personnel and sensitive equipment to avoid accidents. Additionally, consider documenting maintenance and inspection schedules to keep a comprehensive record of the valve’s performance over time.

How Do Boiler Relief Valves Function in a Heating System?

Boiler relief valves play a crucial role in maintaining safety and efficiency within a heating system. They are designed to release excess pressure that builds up within the boiler, a scenario that could lead to catastrophic failures if unaddressed. When the pressure exceeds a predetermined level, the relief valve automatically opens, allowing steam or water to escape and thereby reducing pressure to safer levels. This self-regulating mechanism is essential for preventing damage to the system and ensuring that it operates within its designed parameters.

In addition to pressure relief, these valves contribute to the overall efficiency of the heating system. By disallowing the pressure from becoming too high, they help maintain optimal thermal energy transfer, ensuring that the heating process is both effective and safe. Proper installation and regular maintenance of the boiler relief valves are vital, as any malfunction can lead to severe consequences, including system failure or dangerous pressure accumulation. Understanding how these components function aids operators in recognizing potential issues before they escalate, thereby enhancing the longevity and reliability of the heating system.

What Are the Common Signs of a Faulty Relief Valve?

A boiler relief valve is a critical safety component that helps prevent dangerous situations in heating systems by discharging excess pressure. Recognizing the signs of a faulty relief valve is essential to maintaining both efficiency and safety. One common indicator is frequent leaks or dripping from the valve itself, which can suggest a malfunction. According to the American Society of Mechanical Engineers (ASME), nearly 30% of boiler incidents arise from improperly maintained relief valves, highlighting the importance of monitoring these devices closely.

Another prevalent sign of a faulty relief valve is an unusual hissing or whistling noise when the boiler is operating. This can indicate that the valve is constantly opening and closing in an attempt to regulate pressure, which may mean it’s no longer functioning effectively. Furthermore, if pressure readings on the boiler gauge consistently exceed normal operating levels (typically between 15-30 psi for residential boilers), it is a clear signal that the relief valve may be stuck or damaged. As per data from the Engineering Maintenance Association, regular inspections and maintenance can reduce mechanical failures by up to 25%, underlining the necessity of staying vigilant for these signs to ensure optimal performance and safety.

What Factors Should Influence the Selection of a Relief Valve?

When selecting a relief valve, several critical factors should guide the decision-making process to ensure safety and efficiency in operation. Firstly, the valve's set pressure is paramount; it must be tailored to the specific system requirements to prevent overpressure events without compromising performance. Consideration should also be given to the expected flow capacity during relief scenarios, as inadequate flow can lead to system failures. Additionally, the nature of the fluid—be it gas, steam, or liquid—will influence the material and design of the valve, ensuring compatibility and durability in various operating conditions.

Another essential factor is the installation location and the physical space available. Relief valves must be easily accessible for maintenance and testing, and their placement can affect their effectiveness in protecting the system. Environmental conditions, such as temperature extremes or corrosive surroundings, may also dictate the valve's material selection and design. Lastly, compliance with industry standards and regulations cannot be overlooked, as they ensure that the relief valve meets safety and performance criteria necessary for protecting both personnel and equipment.

How Can You Maintain and Test Boiler Relief Valves Safely?

Maintaining and testing boiler relief valves is crucial for ensuring the safety and efficiency of boiler systems. According to the National Board of Boiler and Pressure Vessel Inspectors, regular inspections are essential, as improperly functioning relief valves can lead to disastrous consequences, including boiler explosions or system failures. Industry standards recommend conducting a thorough test of the relief valve at least once a year to verify that it opens at the set pressure and reseals properly once pressure decreases. This proactive approach not only enhances the safety of operators but also minimizes downtime and maintenance costs.

To safely maintain and test relief valves, it is important to follow specific protocols. Before engaging in any testing, ensure that the boiler system is depressurized and cooled down to prevent any accidental releases of steam or pressure. During testing, technicians should utilize calibrated pressure gauges to confirm the set point of the relief valve, making adjustments as necessary while adhering to the manufacturer’s specifications. Additionally, the American Society of Mechanical Engineers (ASME) highlights the importance of documenting all maintenance activities, which helps maintain compliance with regulatory requirements and supports the operational integrity of the boiler system. Regular training for personnel on testing procedures and safety protocols further underscores a commitment to maintaining safe operational standards in the industry.

Top 10 Common Questions About Boiler Relief Valves Answered - How Can You Maintain and Test Boiler Relief Valves Safely?

| Question | Answer | Maintenance Tips |

|---|---|---|

| What is a boiler relief valve? | A safety device designed to relieve excess pressure from the boiler. | Regularly inspect for leaks and corrosion. |

| How does a relief valve work? | It opens automatically to prevent excessive pressure build-up. | Test regularly to ensure it opens at the correct pressure. |

| How often should I test my boiler relief valve? | At least once a year or as recommended by the manufacturer. | Schedule testing during routine maintenance. |

| What are the signs of a faulty relief valve? | Leaks, rust, or failure to open under pressure. | Replace if any signs of wear are detected. |

| Can I clean my boiler relief valve? | Yes, but handle with care and follow manufacturer guidelines. | Use appropriate cleaning agents and tools. |

| What should I do if the valve leaks? | Shut down the boiler and contact a professional. | Do not attempt to fix it yourself unless qualified. |

| Is it safe to manually test the relief valve? | Yes, but ensure you follow safety protocols. | Wear protective gear and ensure proper drainage. |

| What are the consequences of a malfunctioning valve? | Potential boiler explosion or severe damage. | Immediate replacement is recommended. |

| How can I ensure my boiler operates safely? | Regular maintenance and prompt repairs of any issues. | Follow a maintenance schedule and keep records. |

| What is the lifespan of a boiler relief valve? | Typically 5 to 10 years, but it varies by usage and maintenance. | Monitor its performance and replace as needed. |

Related Posts

-

Top 10 Temperature and Pressure Relief Valves to Enhance Safety and Efficiency in Industrial Applications

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

Top 10 Vacuum Relief Valves for Optimal Pressure Management in Industrial Applications

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

Top 5 Pressure Vacuum Relief Valves: Maximizing Safety and Efficiency

-

Understanding the Importance of Air Compressor Relief Valve in 2025 Top Models