2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency

In the realm of industrial safety, the importance of selecting the right pressure safety valve (PSV) cannot be overstated. According to a recent report by the American Society of Mechanical Engineers (ASME), improper PSV selection accounts for approximately 30% of pressure-related incidents in manufacturing facilities. These incidents not only endanger personnel but also lead to significant financial losses, prompting stakeholders to prioritize safety valve efficiency in system design.

Renowned industry expert Dr. Emily Carter, a leading authority on safety systems, emphasizes, "A well-chosen pressure safety valve is a critical component that ensures the reliability and efficiency of an entire system." As industries evolve and new technologies emerge, the demand for PSVs that can seamlessly integrate with advanced systems increases. The challenge lies in navigating the myriad of options available in the market and understanding the specific requirements of each application.

In this context, the process of choosing the right pressure safety valve becomes essential for optimizing system performance and ensuring compliance with regulatory standards. This paper aims to provide comprehensive guidance on the factors that must be considered when selecting a PSV, ensuring that industry professionals can make informed decisions that safeguard their operations.

Understanding Pressure Safety Valve Types and Their Applications

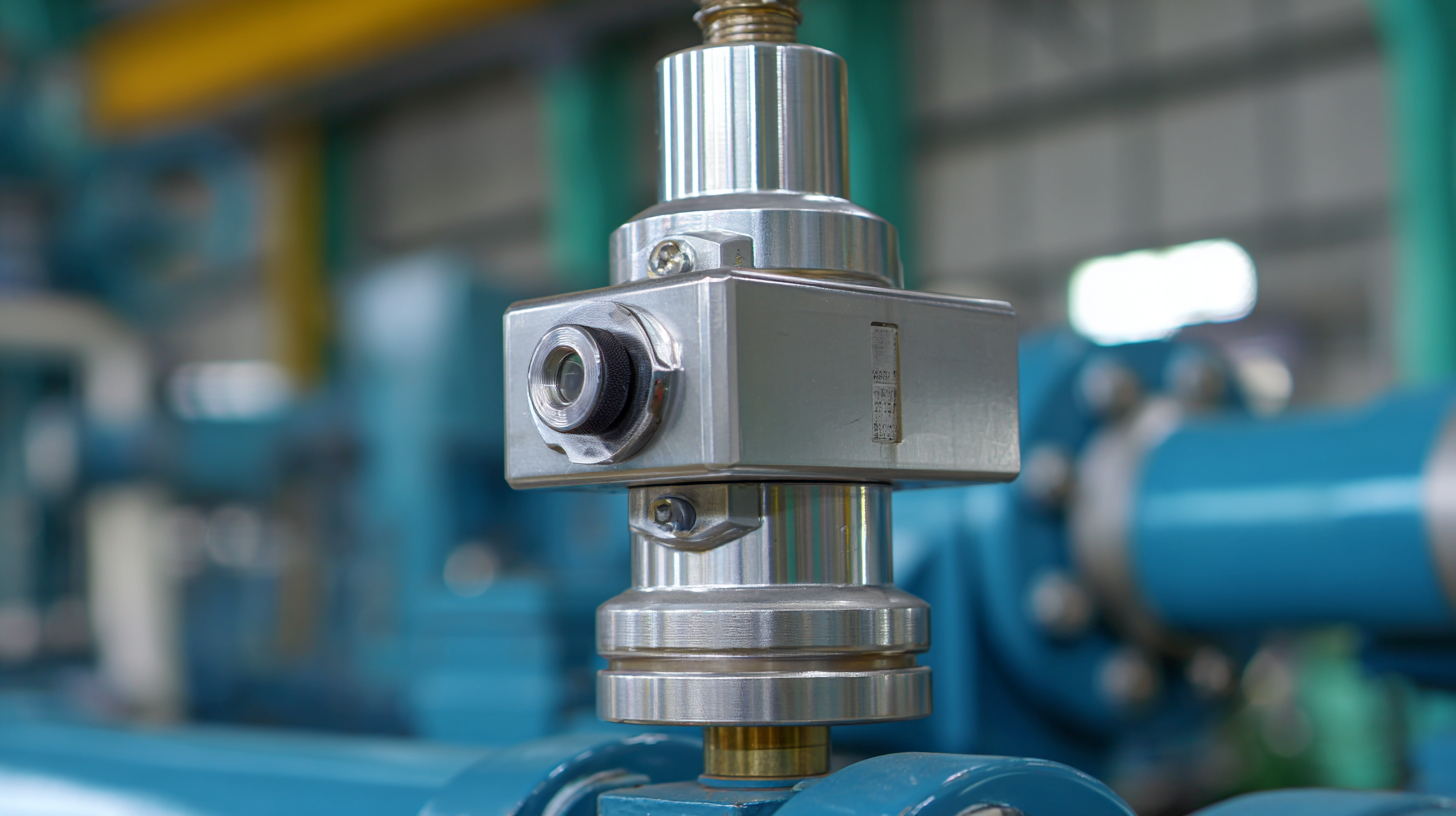

When selecting the right pressure safety valve (PSV), it's crucial to understand the various types available and their specific applications. According to a 2021 report by the International Society of Automation (ISA), the global market for PSVs is projected to grow at a CAGR of 5.4% from 2021 to 2026, driven by increased safety regulations and the expansion of the oil and gas sector. The most common types of PSVs include spring-loaded, pilot-operated, and rupture disk valves, each serving unique purposes. For instance, spring-loaded PSVs are ideal for vapor and gas applications, offering quick response times and reliability under standard operating conditions.

Pilot-operated safety valves, on the other hand, are designed for larger systems where high capacity and precise pressure control are paramount. A white paper from the American Society of Mechanical Engineers (ASME) indicates that these valves can enhance system efficiency by up to 20% compared to traditional spring-loaded designs. Understanding the operational context and requirements of your system will aid in selecting a PSV that not only meets safety standards but also optimizes overall efficiency, particularly in industries like petrochemical processing and steam generation, which account for around 30% of PSV applications globally.

Key Factors in Selecting Pressure Safety Valves for Different Systems

When selecting pressure safety valves (PSVs) for different systems, several key factors must be considered to ensure optimal system efficiency. Firstly, it is essential to understand the specific application and operating conditions, such as the type of fluid, pressure range, and temperature. This information aids in determining the appropriate set pressure and valve materials, which are crucial for preventing potential leaks or failures. For example, corrosive substances require PSVs made from resistant materials to maintain integrity under harsh conditions.

Another significant factor is the flow capacity of the valve, which must be compatible with the system’s requirements to avoid overpressure situations. The valve’s size and configuration should be selected based on the expected flow rates, including any potential surges. Additionally, compliance with industry standards and regulations cannot be overlooked, as adherence to these guidelines ensures safety and reliability. Ultimately, a thorough assessment of these factors will lead to the selection of the right pressure safety valve, contributing to the overall efficiency and safety of the system.

Impact of Valve Sizing and Set Pressure on System Efficiency

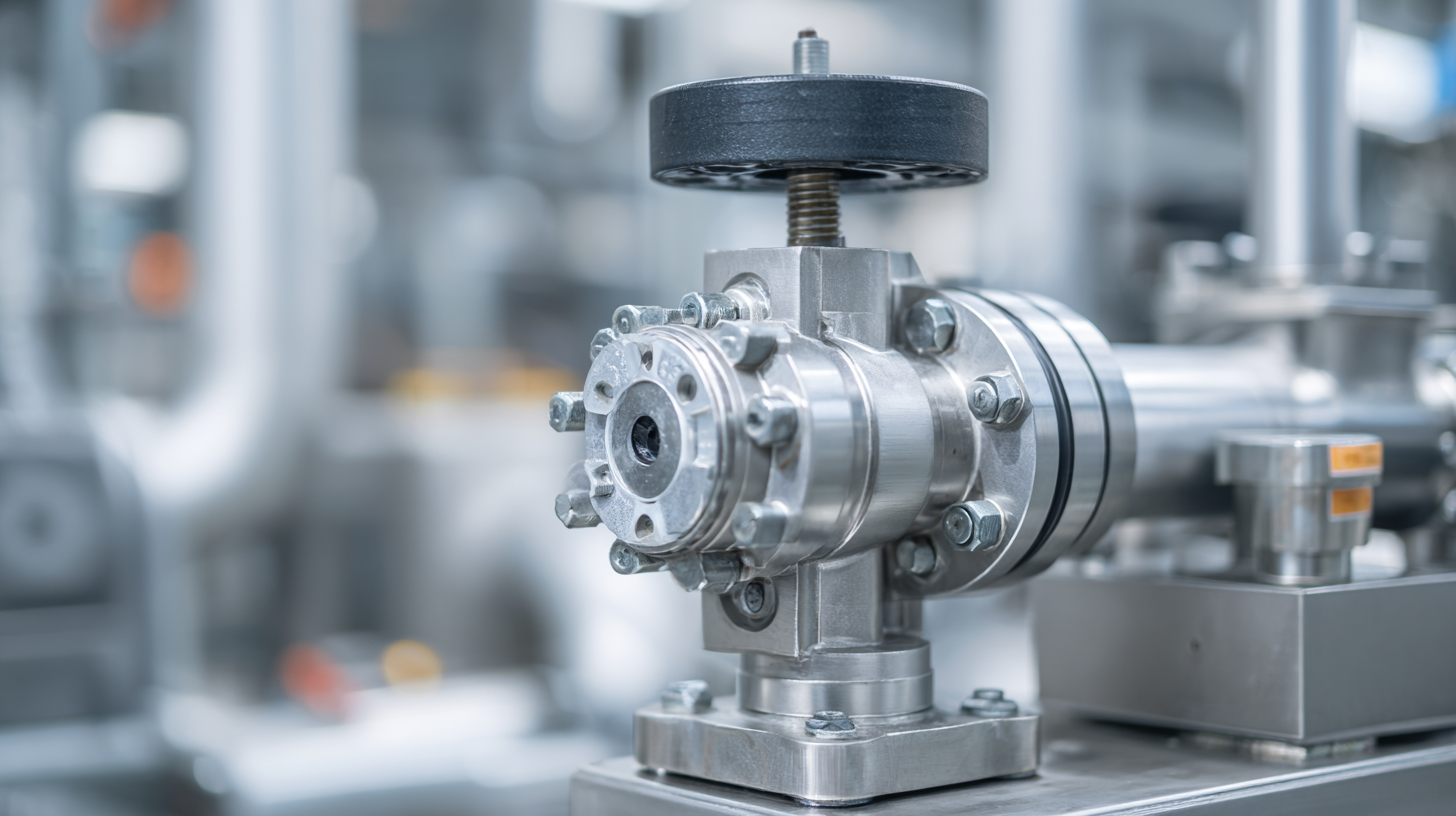

When selecting a pressure safety valve (PSV), understanding the impact of valve sizing and set pressure is critical for ensuring optimal system efficiency. The sizing of the valve significantly influences how well the entire system responds to pressure fluctuations. A valve that is too small may not relieve enough pressure during an overpressure event, risking equipment damage and efficiency loss. Conversely, an oversized valve can lead to excessive cycling, causing unnecessary wear and tear on the system components. Therefore, achieving the correct balance in sizing the PSV directly correlates with the reliability and operational efficiency of the system.

Set pressure is another crucial factor that affects system performance. The set pressure must be carefully chosen to match the operational parameters of the system. If the set pressure is too low, the valve may open frequently, leading to frequent pressure drops that waste energy and disrupt processes. On the other hand, if the set pressure is too high, it may not activate in time to prevent an overpressure scenario. The strategic selection of both valve sizing and set pressure not only enhances safety measures but also plays a vital role in optimizing the overall efficiency of the operations, ultimately contributing to better economic outcomes.

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency

This chart demonstrates the impact of valve sizing on system efficiency. Properly sized pressure safety valves achieve optimal system performance, as depicted by the highest efficiency percentage among the categories. An undersized valve significantly decreases efficiency, while an oversized valve performs moderately.

Evaluating Materials and Designs for Enhanced Reliability and Performance

When selecting a pressure safety valve (PSV) for optimal system efficiency, evaluating materials and designs is crucial for ensuring enhanced reliability and performance. The materials used in the construction of a PSV must withstand the specific operational conditions, including temperature fluctuations, corrosive environments, and potential pressure spikes. For instance, high-alloy steels and corrosion-resistant alloys are often preferred in chemical processing applications, while more standard materials might suffice in less harsh environments. Understanding the application’s requirements allows engineers to choose the right materials that will not only improve durability but also extend the lifecycle of the valve.

Furthermore, the design of the pressure safety valve plays a pivotal role in its functionality. Features such as spring-loaded, pilot-operated, or balanced bellows designs can significantly affect performance under varying pressure conditions. A well-designed PSV can minimize the risk of premature lifting and ensure accurate performance during pressure relief scenarios. Engaging with manufacturers that prioritize innovative design methodologies will yield valves that not only meet regulatory standards but also enhance system efficiency through reliable operation. Thus, both material selection and design considerations should not be overlooked when aiming for optimal performance in pressure safety valves.

Regulatory Standards and Compliance Considerations in Valve Selection

When selecting a pressure safety valve (PSV), understanding regulatory standards and compliance is paramount. Different industries, such as petrochemical and pharmaceuticals, are governed by specific guidelines that dictate the requirements for safety valves. For instance, the American Society of Mechanical Engineers (ASME) has established standards that ensure reliability and safety in pressure relief applications. Compliance with these standards not only ensures the safety of operations but also protects against potential legal liabilities arising from malfunction or failures.

Additionally, it is essential to consider local regulations that might impose stricter requirements than national standards. Familiarity with the guidelines set forth by organizations like the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA) can equip engineers and safety professionals to make informed decisions. This knowledge will help ensure that the selected valve not only fits the technical specifications of the system but also meets all compliance criteria, ultimately enhancing system efficiency and safety while avoiding costly penalties associated with non-compliance.

2025 How to Choose the Right Pressure Safety Valve for Optimal System Efficiency - Regulatory Standards and Compliance Considerations in Valve Selection

| Parameter | Standard/Regulation | Material Compliance | Pressure Range (psi) | Temperature Range (°F) |

|---|---|---|---|---|

| Maximum Allowable Working Pressure | ASME BPVC Section I | A516 Gr. 70 | 50 - 1500 | -20 to 650 |

| Operation Type | API 526 | Stainless Steel | 30 - 2500 | -40 to 750 |

| Size | ISO 4126 | Copper Alloy | 1/2" - 6" | -10 to 250 |

| Testing Requirements | PED 2014/68/EU | Alloy Steel | 60 - 3000 | -30 to 600 |

Related Posts

-

Understanding the Role of Temperature and Pressure Relief Valves: Key Data and Insights for Safety Compliance

-

Understanding the Importance of Relief Valves in Industrial Applications

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges

-

2025 Top 5 Safety Relief Valve Innovations You Should Know

-

Unlocking Efficiency: A Comprehensive Guide to Hydraulic Relief Valve Performance Metrics in Industrial Applications