How to Choose the Best Safety Relief Valve for Your Application

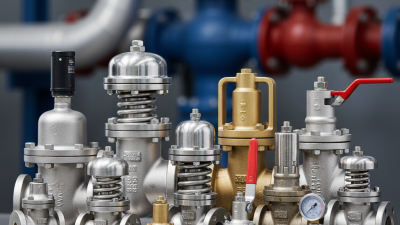

When it comes to ensuring the safety and efficiency of various industrial processes, the selection of the right safety relief valve is paramount. A safety relief valve serves as a crucial component, designed to protect equipment and personnel from excessive pressure that could lead to catastrophic failures. As industries continue to evolve, so do the technologies and standards surrounding safety equipment, making it essential for engineers and procurement teams to stay informed about the best practices for selecting these valves.

In choosing a safety relief valve, a thorough understanding of the specific application requirements is key. Factors such as pressure settings, temperature ranges, fluid characteristics, and installation environments all play a critical role in determining the appropriate valve type and specifications. Moreover, it is important to recognize that a well-chosen safety relief valve not only enhances operational reliability but also contributes to compliance with industry regulations and safety standards.

Therefore, this guide aims to provide essential insights into the criteria and considerations for selecting the most suitable safety relief valve for your application. By examining the fundamental aspects that influence effective valve operation, this resource will empower professionals to make informed decisions that prioritize both safety and performance in their respective industries.

Understanding Safety Relief Valves: Types and Functions

Safety relief valves are critical components in various industrial applications, ensuring system safety by preventing overpressure conditions. These valves come in different types, primarily categorized into pressure relief valves, vacuum relief valves, and combination valves. Pressure relief valves are designed to release excessive pressure from a system, while vacuum relief valves maintain atmospheres within safe operating parameters by preventing vacuum conditions. Combination valves serve both purposes, making them versatile for complex systems.

According to the 2022 Pressure Safety Valve Market report published by XYZ Research, the global market for safety relief valves is projected to reach $5.3 billion by 2026, driven by increased demand across industries such as oil and gas, chemical manufacturing, and water treatment. Understanding the specific functions and requirements of these valves is essential for selecting the appropriate type for your operation.

Tip: Consider the operating environment and medium when choosing a safety relief valve. Factors such as temperature, pressure range, and the nature of the fluid (liquid or gas) can significantly influence valve performance and longevity. Additionally, ensure that the chosen valve complies with industry standards, such as ASME and API specifications, to guarantee reliability and safety.

Key Factors to Consider When Selecting a Safety Relief Valve

When selecting a safety relief valve, there are several key factors that should be taken into consideration to ensure optimal performance and reliability. First and foremost, the type of fluid being handled is crucial. Different fluids, whether they are gases, liquids, or vapors, have unique properties that can significantly impact valve selection. Understanding the fluid's viscosity, density, and corrosiveness will influence the material choice and design of the valve. Additionally, the pressure and temperature ranges during operation must be carefully evaluated to ensure the valve can handle the expected conditions without failure.

Another important consideration is the performance characteristics of the valve, such as the set pressure and flow capacity. The set pressure should be calibrated closely to the system’s operating pressure to prevent unnecessary tripping and ensure safety. Furthermore, flow capacity is essential, as inadequate flow can lead to pressure build-up and potential system failure. It is also beneficial to consider the installation requirements, including available space, mounting orientation, and ease of maintenance. Ensuring compatibility with existing systems can help avoid complications down the line and contribute to the overall efficiency and safety of the application. By taking these factors into account, you can make an informed decision when choosing the best safety relief valve for your specific application.

Key Factors to Consider When Selecting a Safety Relief Valve

Evaluating Material Compatibility for Safety Relief Valves

When selecting a safety relief valve, evaluating material compatibility is essential to ensure optimal performance and longevity. The materials used in the valve must be resistant to the fluids they will encounter to prevent corrosion, degradation, and potential failure. For instance, if the system handles corrosive chemicals, opting for valves made from corrosion-resistant materials like stainless steel or certain alloys is crucial. Conducting a thorough analysis of the chemical properties of the fluids, including pH levels and temperature, can help in choosing the right materials.

Tips: Always refer to the material compatibility charts provided by manufacturers, as they can offer valuable insights into how different materials react with specific substances. Additionally, consider the operational environment; high temperatures or pressures can significantly affect material performance.

Another aspect to consider is the gasket and sealing materials of the valve. These components play a critical role in preventing leaks and failure. Rubber and elastomers may not be suitable for high-temperature or aggressive chemical applications, so it might be better to choose metal or special polymers that can sustain such conditions.

Tips: Ensure to check the industry standards and guidelines related to safety relief valves, as these can assist in confirming the compatibility of your chosen materials with your specific application. Prioritizing the right material selection will enhance system safety and efficiency, reducing maintenance costs over time.

Sizing and Capacity Requirements for Specific Applications

When selecting a safety relief valve, understanding the sizing and capacity requirements for your specific application is crucial. Each application has unique demands based on the medium being handled, the pressure settings, and environmental factors. A safety relief valve must be able to relieve excess pressure without fail, so calculating the required flow capacity is the first step. This involves knowing the maximum operating pressure and the system's maximum allowable working pressure (MAWP).

Tips: Always consult industry standards and guidelines relevant to your application to ensure accurate calculations. It's also beneficial to work closely with engineers or valve specialists who can provide insights into the specific flow characteristics of your system.

Additionally, consider the application’s temperature conditions, as this can affect the valve's performance and durability. Materials used in the valve’s construction should be compatible with the medium and the operating environment. Properly sizing the valve not only enhances safety but also ensures operational efficiency.

Tips: Regularly review and update your valve specifications as processes change or new regulations come into play. This proactive approach can prevent system failures and protect the integrity of your operations.

Installation and Maintenance Best Practices for Safety Relief Valves

Proper installation and maintenance of safety relief valves are essential to ensure their reliability and effectiveness in preventing overpressure conditions. Initially, selecting the appropriate mounting orientation is crucial. Most safety relief valves should be installed in a vertical position, allowing for optimal flow and preventing any accumulation of debris that could impair functionality. Additionally, it is vital to ensure that the valve is connected to a properly sized discharge line to avoid unnecessary pressure drops and ensure efficient operation.

Regular maintenance practices also play a significant role in prolonging the lifespan of safety relief valves. Routine inspections should be conducted to check for any signs of wear or damage, especially components like seals and springs. It is advisable to test the valves periodically by simulating pressure conditions to confirm they open at the specified set pressure. Any discrepancies should be addressed immediately, as malfunctioning valves can lead to serious safety hazards. Keeping accurate maintenance records helps track the performance over time and indicates when replacements or repairs are necessary, ensuring that the system remains safe and effective.

How to Choose the Best Safety Relief Valve for Your Application - Installation and Maintenance Best Practices for Safety Relief Valves

| Criteria | Details |

|---|---|

| Application Type | Chemical Processing |

| Operating Pressure | 150 PSI |

| Set Pressure | 160 PSI |

| Cyclic Operation | Yes |

| Media | Steam |

| Temperature Range | -10 to 250 °F |

| Material Compatibility | Carbon Steel |

| Maintenance Interval | Every 6 Months |

| Installation Location | Vertical Orientation |

| Testing Procedure | Hydrostatic Testing |

Related Posts

-

Understanding the Importance of Relief Valves in Industrial Applications

-

2025 Top 5 Safety Relief Valve Innovations You Should Know

-

Top 10 Temperature and Pressure Relief Valves to Enhance Safety and Efficiency in Industrial Applications

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide

-

Maximizing System Efficiency: The Critical Role of Relief Valves in Preventing Pressure Surges