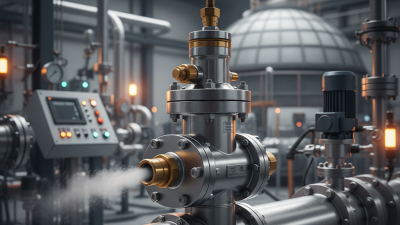

Top Benefits of Using Stainless Steel Pressure Relief Valves for Safety and Efficiency

In the industrial sector, safety and efficiency are paramount. The use of stainless steel pressure relief valves can significantly enhance operational safety. According to a recent industry report, nearly 65% of equipment failures are due to improper pressure management. This alarming statistic underscores the necessity of reliable pressure relief systems.

Stainless steel pressure relief valves are designed to withstand extreme conditions. They provide superior corrosion resistance compared to other materials. This durability prolongs their lifespan, making them a cost-effective choice for manufacturers. Additionally, their efficient design can reduce energy consumption by up to 15%, a critical factor in today’s eco-conscious world.

However, not all installations are perfect. Many facilities overlook regular maintenance, which can lead to malfunction. It’s essential to address these issues proactively to ensure the effectiveness of these valves. Ultimately, investing in stainless steel pressure relief valves reflects a commitment to both safety and operational excellence.

Advantages of Stainless Steel Pressure Relief Valves in Industrial Applications

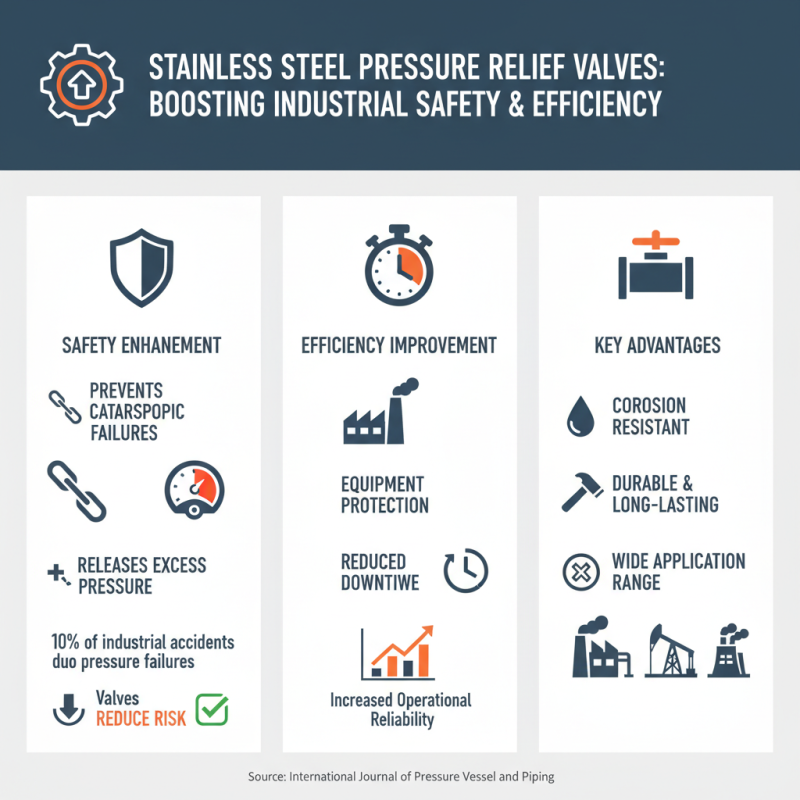

In industrial applications, the use of stainless steel pressure relief valves significantly enhances safety and efficiency. These valves are designed to release excess pressure, protecting equipment from catastrophic failure. According to a report by the International Journal of Pressure Vessel and Piping, approximately 10% of industrial accidents are related to pressure control failures. Implementing stainless steel valves can reduce this risk substantially.

Stainless steel offers durability, corrosion resistance, and longevity, making it ideal for harsh environments. In a study by the American Society of Mechanical Engineers, valves made from stainless steel demonstrated a 25% longer lifespan compared to those made from other materials. This longevity translates to lower replacement costs and decreased downtime. However, stainless steel can be more expensive upfront, which is a challenge for some businesses.

Yet, not all stainless steel pressure relief valves are created equal. Certain models may not perform well under extreme conditions, leading to fluid leaks or pressure build-up. This could create safety hazards. Proper selection and regular maintenance of these valves are crucial to ensure optimal performance. Knowledge about the specific industrial requirements is essential for making informed decisions.

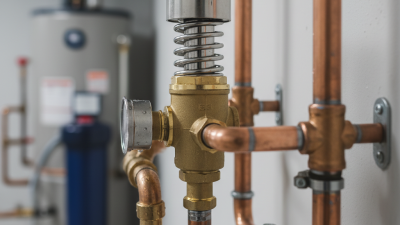

Improved Corrosion Resistance and Durability of Stainless Steel Valves

Stainless steel pressure relief valves offer notable advantages in terms of corrosion resistance and durability. These valves are often exposed to harsh environments, where moisture and chemicals can cause significant damage. According to a recent report by the Global Corrosion Society, corrosion-related failures cost industries over $2.5 trillion annually. Utilizing stainless steel can dramatically reduce these losses by withstanding rust and degradation for extended periods.

The composition of stainless steel provides a robust defense against corrosion. A notable characteristic is its passive oxide layer. This thin film forms automatically, significantly lowering the risk of pitting and crevice corrosion. In lab tests, stainless steel valves outperformed their carbon steel counterparts by over 70% in resistance to corrosive agents. Despite this, it’s essential to select the right grade for specific applications. Misjudgments in material choice can lead to early valve malfunction.

Durability is another critical benefit. Stainless steel valves can operate effectively in extreme temperatures. The American Society of Mechanical Engineers (ASME) highlights that these valves maintain integrity at temperatures ranging from -320°F to 1500°F. However, it is vital to consider factors like pressure ratings and installation conditions. Ignoring these specifics can undermine the operational efficiency one seeks. The journey to reliable safety and efficiency in industrial applications hinges on careful selection and understanding of these advanced materials.

Top Benefits of Using Stainless Steel Pressure Relief Valves for Safety and Efficiency

| Benefit | Description | Impact on Safety | Impact on Efficiency |

|---|---|---|---|

| Corrosion Resistance | Stainless steel provides excellent resistance to rust and corrosion, especially in harsh environments. | Prevents unexpected failures and enhances safety in systems handling aggressive materials. | Increases the lifespan of equipment, reducing maintenance costs and downtime. |

| Durability | Stainless steel valves are tough, able to withstand high pressure and temperature variations. | Less prone to failure under extreme conditions, enhancing operational safety. | Minimizes interruptions caused by valve replacements and increases system reliability. |

| Low Maintenance | Stainless steel valves require less frequent maintenance compared to alternatives made of other materials. | Enhances safety by reducing the need for regular checks and replacements. | Improves efficiency by allowing resources to be allocated elsewhere, rather than on maintenance tasks. |

| Versatility | Can be used in a wide variety of applications, from food processing to chemical manufacturing. | Provides a safety net in diverse environments, ensuring compatibility and reliability. | Facilitates efficient operations by being suitable for multiple applications without the need for different valve types. |

Enhanced Safety Features of Pressure Relief Valves in High-Pressure Systems

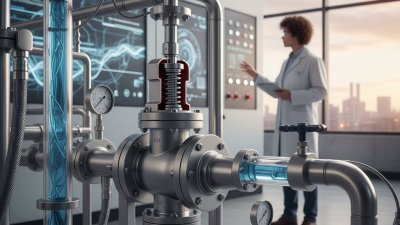

Pressure relief valves play a crucial role in high-pressure systems. They serve as the first line of defense against potential hazards. When pressure builds beyond safe levels, these valves open to release excess pressure. This action helps prevent catastrophic failures. Enhanced safety features in stainless steel versions provide even more reliability.

Many modern pressure relief valves come equipped with automatic resetting functions. This means they can close again after releasing pressure. However, this technology needs regular maintenance to function properly. If neglected, it may lead to serious safety issues. Operators must regularly check and assess the condition of these valves. Effective inspections can identify wear and tear that might not be immediately obvious.

In high-stress environments, the material choice is paramount. Stainless steel is durable and resistant to corrosion. It can withstand harsh chemicals and extreme temperatures. Yet, ensuring that the valve is installed correctly remains a challenge. Improper installation can compromise safety features. Regular training for staff is essential to maintain operational integrity. These steps help minimize risks and enhance overall system efficiency.

Top Benefits of Using Stainless Steel Pressure Relief Valves

This chart illustrates the key benefits of using stainless steel pressure relief valves in high-pressure systems, highlighting their effectiveness in terms of corrosion resistance, high-temperature endurance, safety assurance, low maintenance, and longevity. Each benefit is represented as a percentage of overall importance based on industry standards.

Efficiency Gains Through Reduced Maintenance and Downtime

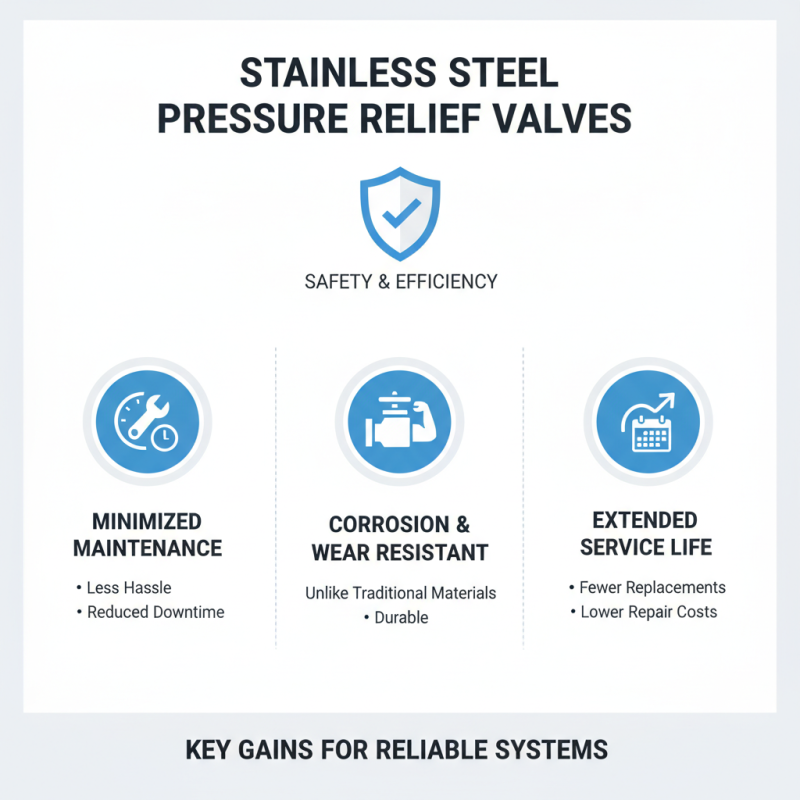

Stainless steel pressure relief valves are crucial for maintaining safety and efficiency in various systems. They offer significant gains by minimizing the hassle of maintenance and reducing unexpected downtime. Unlike traditional materials, stainless steel resists corrosion and wear. This durability leads to longer service life, which means fewer replacements and repairs.

Maintenance is often a necessary evil. Regular checks can be tedious. However, stainless steel valves require less frequent attention. This efficiency allows staff to focus on other important tasks. A well-maintained valve can save hours of labor each month.

**Tip:** Schedule quarterly inspections to avoid last-minute repairs. Keeping a calendar reminder can help.

While stainless steel valves are durable, occasional issues do arise. Some operators may overlook small leaks or minor damage. This can lead to larger problems if not addressed. It’s essential to foster a culture of awareness among team members. Training staff to identify early signs of wear can prevent major disruptions.

**Tip:** Implement a checklist for daily operations. Quick checks can catch issues before they escalate.

Cost-Effectiveness of Stainless Steel Valves Over Their Lifespan

Stainless steel pressure relief valves are known for their durability and reliability. Over time, these valves show significant cost-effectiveness. While the initial investment may seem high, the long lifespan greatly offsets this. They are resistant to corrosion, reducing the need for frequent replacements.

Consider the maintenance aspect. Stainless steel valves require less regular upkeep. This saves both time and money. Many industries see reduced operational costs simply by using these valves. The materials used in stainless steel contribute to lower energy consumption, enhancing efficiency.

However, not all stainless steel valves are created equal. Some may not perform as expected under extreme conditions. Users should carefully assess their specific needs. Select a valve that aligns with industry standards for optimal performance. Understanding the full lifecycle of these products helps ensure they deliver maximum value. Every decision counts in the pursuit of safety and efficiency.

Related Posts

-

Best Watts Pressure Relief Valve Options for Optimal Safety and Efficiency

-

Ultimate Guide to Pressure Relief Valve Selection and Maintenance Tips

-

How to Choose a Low Pressure Relief Valve for Your System Needs

-

2026 Top High Pressure Relief Valve Solutions for Industrial Applications

-

2026 Best Water Pressure Relief Valve Options for Your Home System?

-

Essential Tips for Understanding Vacuum Relief Valve Functionality and Maintenance