2026 Top Stainless Steel Pressure Relief Valve Models You Should Consider?

When it comes to safety and efficiency in industrial applications, the choice of a stainless steel pressure relief valve is crucial. Renowned expert John Smith, who specializes in fluid dynamics, once stated, “Choosing the right pressure relief valve can mean the difference between safety and disaster.” His words resonate in a market filled with choices, where the quality and design of each valve vary significantly.

In 2026, the landscape of stainless steel pressure relief valves will evolve, presenting new models that promise enhanced performance and reliability. These valves are essential for preventing overpressure conditions in various systems, ensuring machinery operates smoothly and safely. The right models not only comply with industry standards but also adapt to specific needs.

Many engineers and operators may find themselves overwhelmed by options. Questions often arise: Are the materials durable? Is the design optimized for efficiency? It’s vital to reflect on these choices carefully. The implications of a poorly selected valve can lead to serious consequences in both safety and operational costs. In this dynamic environment, exploring top models can provide valuable insights for making informed decisions.

2026 Overview of Stainless Steel Pressure Relief Valves

In 2026, stainless steel pressure relief valves are critical in many industrial applications. These valves help manage pressure, ensuring safety and efficiency. Their durability and resistance to corrosion make them ideal for various environments. Industries such as oil, gas, and manufacturing heavily rely on them.

Choosing the right model can be tricky. Focus on the valve's specifications and capacity. Different systems have unique pressure needs. Evaluate the materials used in the construction. Avoid choosing low-quality options, as they may fail under pressure.

**Tip:** Always consult with experts before purchasing. They can provide valuable insights based on your specific needs.

Another consideration is maintenance. Even the best stainless steel pressure relief valves require regular checks. Neglecting maintenance can lead to performance issues.

**Tip:** Develop a maintenance schedule to extend the life of your valves. This practice ensures they operate efficiently and safely, ultimately providing peace of mind.

Key Factors to Consider When Choosing Pressure Relief Valves

When selecting pressure relief valves, several key factors come into play. First, the valve's material should be a priority.

Stainless steel is often favored due to its durability, resistance to corrosion, and ability to withstand high pressures. Reports indicate that stainless steel valves can offer reliability in demanding environments, with a lifespan significantly longer than alternatives, around 20-30% more according to industry studies.

Next, consider the valve's set pressure rating. This number defines the pressure at which the valve will open to release excess pressure. A mismatch here can result in catastrophic failures. Many users underestimate the importance of accurate calibration. A precise set point is crucial to maintain safe operations. Regular maintenance checks should also be part of your plan, even if it seems tedious. Many operators ignore this, leading to preventable accidents.

Finally, think about the application. Different industries have unique requirements. For example, food and beverage sectors may need valves with specific FDA approvals. On the other hand, oil and gas may focus on robust designs to handle extreme conditions. Not every model suits every industry. Research is essential, yet many rush through this step, which can lead to inadequate safety measures. Take time to assess your needs thoroughly, ensuring compatibility and compliance.

Top Rated Stainless Steel Pressure Relief Valve Models of 2026

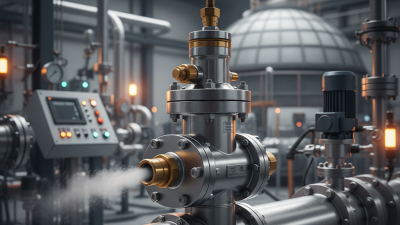

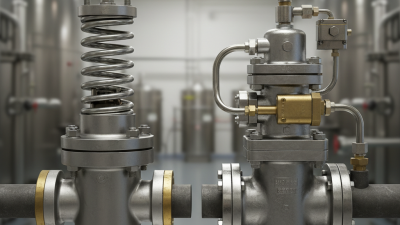

When selecting a stainless steel pressure relief valve, consider efficiency and reliability. The models of 2026 stand out for their durability and performance. These valves are designed to handle high pressures and extreme temperatures. Look for features that enable quick response times under pressure.

Tips: Always check the material specifications. Some stainless steel grades offer better corrosion resistance. Evaluate how each model fits your needs. A well-suited valve ensures safety and longevity.

Consider user feedback on design and performance. Some models may look great but underperform. Read reviews to identify recurring issues. Understanding potential shortcomings helps make a better choice. This prevents costly mistakes down the line.

Performance Comparison of Leading Stainless Steel Pressure Relief Valves

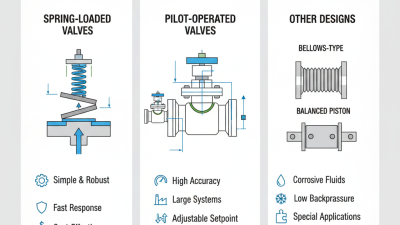

When considering stainless steel pressure relief valves, performance is key. These valves play a critical role in safeguarding systems. They release excess pressure, preventing potential failures. It’s essential to compare various models to identify the best fit for specific applications.

Key performance indicators include response time, flow capacity, and durability. Some valves offer rapid venting capabilities, while others focus on long-term reliability. Testing these aspects can help in choosing the right option. Users might notice that some models excel in specific conditions but falter in others. Balancing these traits is necessary for effective decision-making.

Real-world scenarios can highlight flaws in design or functionality. Some valves may leak under extreme conditions while others exhibit delayed response times. Understanding these performance nuances might require deeper research and testing. This can lead to better choices aligned with operational needs. Always reflect on how the chosen model aligns with both immediate and long-term requirements.

2026 Top Stainless Steel Pressure Relief Valve Performance Comparison

Maintenance Tips for Stainless Steel Pressure Relief Valves

Maintaining stainless steel pressure relief valves is crucial for optimal performance. Regular checks help ensure safety and efficiency. One key tip is to inspect the valves frequently. Look for signs of wear and corrosion. Swift action can prevent larger problems.

Another important aspect is keeping the valve clean. Dirt and debris can compromise functionality. Use a mild detergent and a soft cloth for cleaning. Avoid abrasive materials; they can scratch the surface.

Lastly, consider the installation environment. Extreme temperatures or harsh chemicals can impact valve life. Use protective coverings if necessary. Small changes in your maintenance routine can yield better results. Make it a habit to document your inspections. This record may reveal patterns over time.

2026 Top Stainless Steel Pressure Relief Valve Models You Should Consider

| Model | Pressure Range (psi) | Size (Inches) | Weight (lbs) | Temperature Range (°F) | Application |

|---|---|---|---|---|---|

| Model A | 0-150 | 3/4 | 2.5 | -40 to 250 | Water, Gas |

| Model B | 0-200 | 1 | 3.0 | -20 to 300 | Oil, Chemicals |

| Model C | 0-300 | 1.5 | 4.0 | 0 to 450 | Steam, Air |

| Model D | 0-400 | 2 | 3.5 | -30 to 370 | Oil, Gas |

| Model E | 0-500 | 2.5 | 4.5 | -10 to 500 | Water, Steam |

Related Posts

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

2026 Top High Pressure Relief Valve Solutions for Industrial Applications

-

2026 Top Types of Inline Pressure Relief Valves for Efficient Systems?

-

Top 2 Pressure Relief Valve Types You Should Know?