2026 Top Boiler Relief Valve Innovations and Their Benefits?

In the rapidly evolving world of industrial applications, the boiler relief valve stands out as a vital safety component. These devices prevent dangerous pressure build-up in boilers, ensuring safe operations. Innovations in boiler relief valves for 2026 promise to enhance safety and efficiency, addressing common industry challenges.

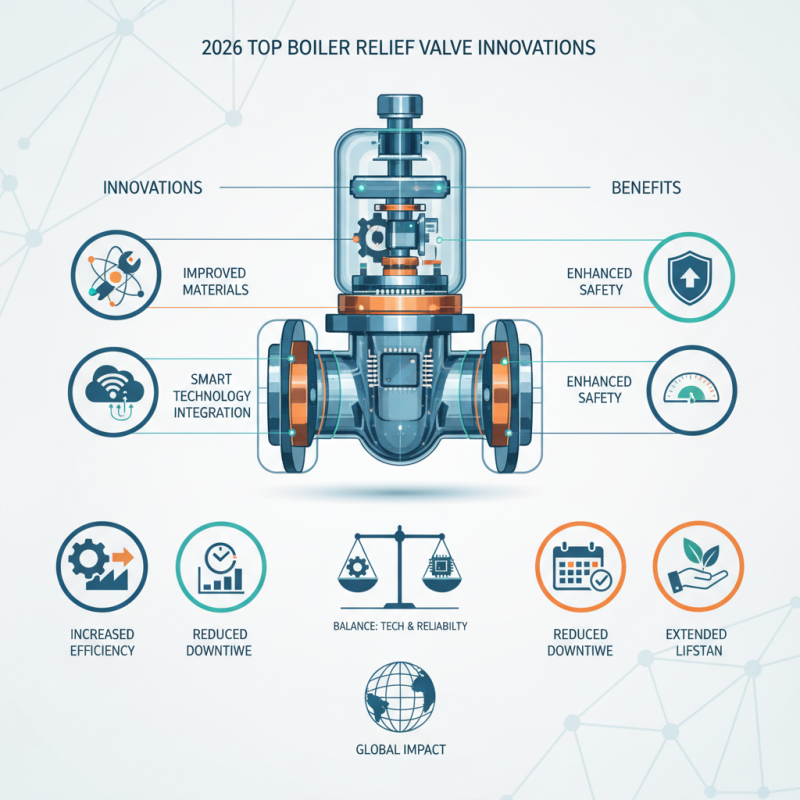

Recent advancements focus on improved materials and smart technology integration. New designs minimize wear and corrosion, extending the life of these crucial components. Incorporating digital monitoring systems enables real-time data collection, allowing for proactive maintenance and reducing downtime. However, not all innovations have been flawless; some may introduce complexity or unexpected maintenance needs.

Exploring these innovations reveals both their potential benefits and inherent challenges. Manufacturers need to consider the balance between new technology and reliability. As we delve into the latest developments in boiler relief valves, understanding their impact on safety and performance is key for industries worldwide.

Emerging Technologies in Boiler Relief Valve Design for 2026

As we look toward 2026, the landscape of boiler relief valve design is ripe for transformation. Emerging technologies are set to enhance safety and efficiency. For example, predictive analytics will now help identify potential failures. According to industry reports, over 40% of boiler malfunctions stem from outdated safety systems. This data underlines the necessity for innovation.

Smart materials are gaining traction. These materials can adjust their properties based on environmental conditions. Such adaptations can significantly reduce the risk of valve failure. With around 25% of valve failures linked to temperature fluctuations, this innovation offers promising benefits. The integration of IoT will allow real-time monitoring, delivering critical updates to operators.

However, the adoption of these technologies is not without challenges. Training personnel on new systems remains a concern. A significant percentage of operators are unfamiliar with advanced technology. Investing in education is crucial to leverage these innovations fully. The balance between progress and practical implementation needs careful consideration. This reflection is essential in an evolving industry.

2026 Top Boiler Relief Valve Innovations and Their Benefits

| Innovation | Description | Benefits | Expected Adoption Rate (%) |

|---|---|---|---|

| Smart Sensors Integration | Incorporation of IoT-enabled sensors for real-time monitoring. | Enhanced safety and predictive maintenance. | 75% |

| Thermal Relief Valves | Valves designed to relieve pressure caused by thermal expansion. | Prevents potential boiler explosions and improves reliability. | 60% |

| Self-Test Mechanisms | Automated testing features for regular function checks. | Reduces maintenance costs and increases operational uptime. | 70% |

| Corrosion-Resistant Materials | Use of advanced alloys and coatings to prevent rust. | Increased lifespan of valve components. | 65% |

| Dynamic Flow Control | Adaptive valves that adjust flow based on pressure changes. | Improves energy efficiency and reduces waste. | 80% |

Key Features of Innovative Boiler Relief Valves for Enhanced Safety

Innovative boiler relief valves are revolutionizing safety measures in industrial settings. The latest models focus on advanced materials and smart technologies. These features enhance durability and responsiveness in high-pressure situations. Many new valves have sensors that detect pressure changes. They send alerts before reaching critical levels.

Another key feature is their compact design. Optimized space usage allows for easier installation and maintenance. Some units offer adjustable settings for precise pressure control. Users can customize the response based on specific needs. However, not every installation takes full advantage of these innovations. Some facilities overlook proper calibration.

Moreover, these valves are designed for easier visibility. Clear indicators help operators monitor performance at a glance. When issues arise, quick identification is crucial. Despite advancements, reliance on human judgment remains a risk. Training personnel on these innovations is essential for maximizing safety. Regular inspections are still necessary to prevent failures.

Advantages of Smart Technology Integration in Boiler Relief Valves

The integration of smart technology in boiler relief valves is transforming the industry. These valves now come equipped with sensors that monitor pressure levels continuously. Real-time data collection is crucial for enhancing safety measures. When pressure builds up too high, these sensors can trigger automatic adjustments. This helps prevent potential system failures.

Furthermore, users benefit from advanced alerts. Notifications can be sent directly to maintenance teams. These features significantly reduce the risk of overlooked issues. However, the reliance on technology raises some concerns. Systems may malfunction, and human oversight can be necessary. It's essential to find a balance between automation and manual checks.

Innovative designs are also increasing efficiency in energy use. Smart valves optimize performance, helping to reduce waste. Some designs allow for remote operation, adding convenience for operators. But with all these advantages, updating existing systems can be challenging. Budget constraints often limit improvements. In many cases, organizations must prioritize which upgrades offer the most significant benefits.

Comparing Traditional vs. Innovative Boiler Relief Valves: A 2026 Perspective

In 2026, the landscape of boiler relief valves is evolving. Traditional designs often struggle under high pressure conditions. They may not open quickly enough, risking safety breaches. Innovative models are changing this narrative. These advancements focus on faster response times and better materials. This ensures that boilers operate within safe pressure limits.

The new designs include enhanced features. Some use advanced sensors to detect pressure fluctuations. Others are made from corrosion-resistant materials, improving longevity. However, innovation comes with its own challenges. Not all facilities may be ready to adopt these technologies. Integration can be complex. Training staff to handle the new systems is crucial but often overlooked. This gap may hinder progress in some industries.

While newer valves offer clear advantages, there is still room for improvement. Some designs may be too sensitive, leading to unnecessary activations. Balancing sensitivity and functionality is essential. As the industry adapts, ongoing feedback from users will be vital. This will help refine the balance between traditional and innovative approaches, ensuring safety and efficiency for all.

2026 Boiler Relief Valve Innovations: Traditional vs. Innovative

This chart compares the performance efficiency and maintenance costs of traditional versus innovative boiler relief valves in 2026. The data shows that innovative valves have a significantly higher performance efficiency while also reducing maintenance costs.

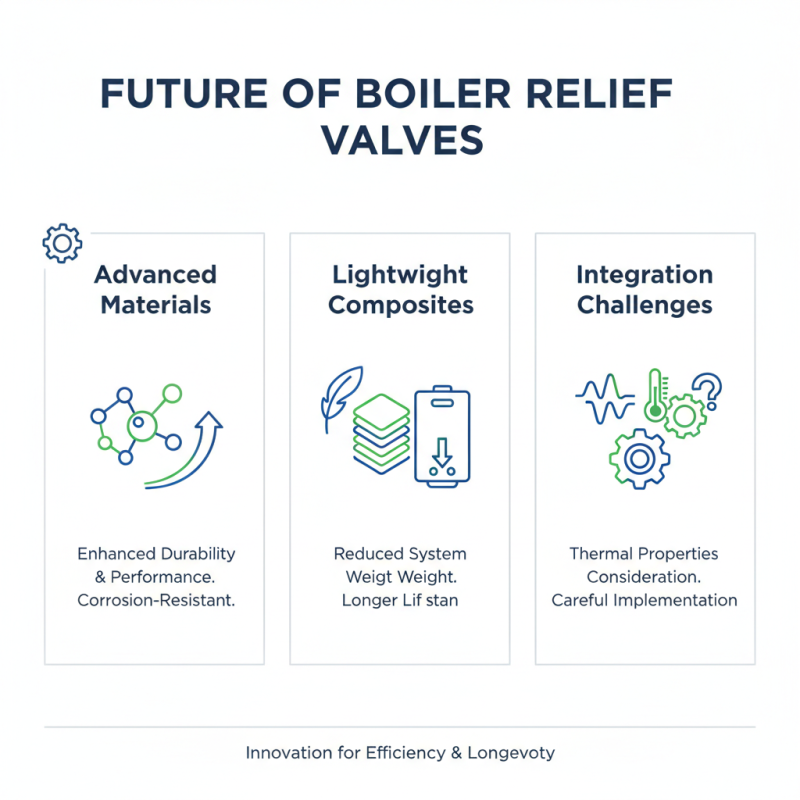

Future Trends in Boiler Relief Valve Materials and Efficiency Improvements

The future of boiler relief valves is poised for transformative changes. Advances in materials promise enhanced durability and performance. Lightweight composites are emerging as alternatives, reducing the overall weight of boiler systems. These materials resist corrosion better, ensuring a longer lifespan. However, the integration of these new materials requires careful consideration of their thermal properties.

Efficiency improvements are another focus. Innovative designs aim to minimize energy loss, optimizing pressure release during operation. Some new valves feature better flow dynamics, which enhances their responsiveness. Yet, the industry faces challenges in balancing cost and performance. High-efficiency valves can burden initial budgets, leading to hesitant adoption. Ongoing research is vital to address these concerns and refine prototypes.

As we explore these innovations, we must remain critical. Not every advancement will meet its promise. Testing and real-world application will reveal their true effectiveness. Regular reviews of operational performance can provide valuable feedback for future developments. Continuous improvement is key in this evolving landscape.

Related Posts

-

Top 10 Common Questions About Boiler Relief Valves Answered

-

Understanding the Importance of Safety Relief Valves in Industrial Applications: A Comprehensive Guide

-

Understanding Vacuum Relief Valves for 2025 Top Applications and Benefits

-

Understanding the Importance of Safety Valves in Industrial Applications

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System