2026 Best Adjustable Pressure Relief Valve Reviews and Buying Guide?

In the world of fluid control systems, the "adjustable pressure relief valve" plays a crucial role. According to a recent market analysis by TechSci Research, the global pressure relief valve market is projected to reach $3.6 billion by 2026. This growth highlights the increasing demand for reliable and adjustable solutions in various industries.

Adjustable pressure relief valves are vital for managing excessive pressure. They prevent equipment damage and ensure safety in systems across oil and gas, pharmaceuticals, and manufacturing sectors. However, the market also reveals challenges. Many users overlook the importance of proper valve selection and maintenance. This oversight can lead to operational failures and costly repairs.

Understanding the features and specifications of these valves is key. High-quality valves can differ significantly in performance and lifespan. As you explore options, consider the risks of using subpar products. Investing time in research can yield significant long-term benefits, ultimately enhancing safety and efficiency in your operations.

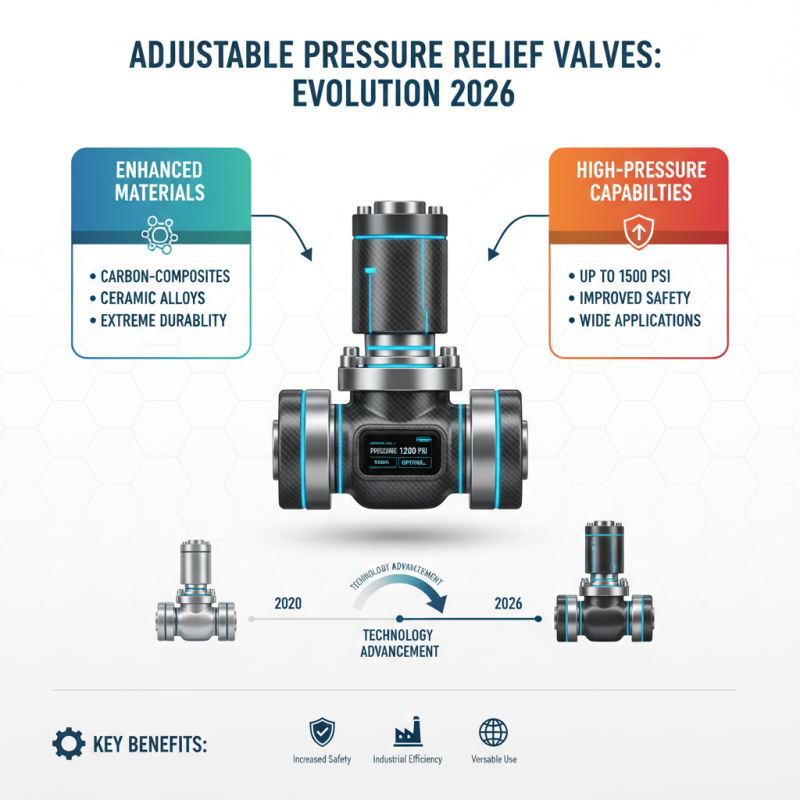

Overview of Adjustable Pressure Relief Valves in 2026

Adjustable pressure relief valves are crucial in various applications. They help manage pressure levels effectively. In 2026, the technology surrounding these valves has evolved significantly. Many designs now feature enhanced materials for durability. This evolution allows users to handle higher pressures with ease.

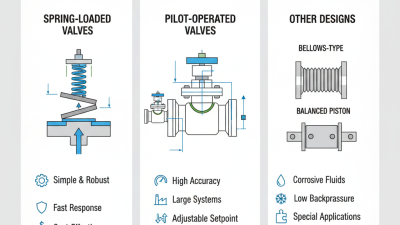

Choosing the right adjustable pressure relief valve can be challenging. Consider the specific needs of your application. Understand the required pressure range. Keep in mind that not all valves fit every situation. Some models may struggle under specific conditions. This variability can lead to performance issues.

**Tips:** Always consult product specifications closely. Look for customer reviews when possible. Experiment with different settings to find what works best. Remember, sometimes trial and error is necessary. Adjustments may be required even after installation.

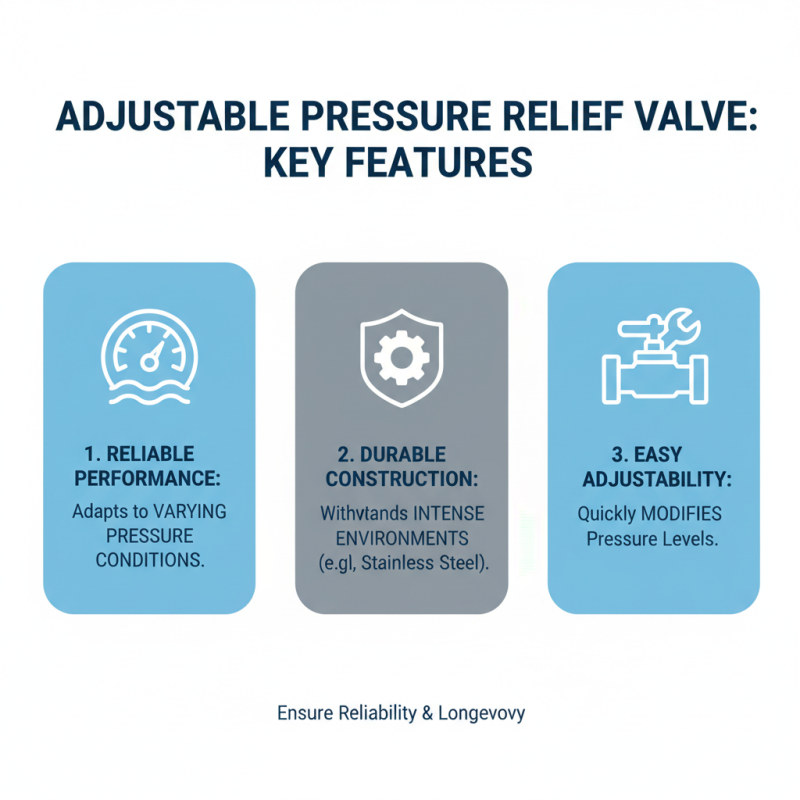

Key Features to Look for in Adjustable Pressure Relief Valves

When choosing an adjustable pressure relief valve, it’s vital to consider key features that ensure reliability. Performance under varying pressure conditions is essential. A durable construction is non-negotiable; look for materials that can withstand intense environments. Adjustability is crucial; valves should easily adapt to changing pressure levels.

Another important aspect is the flow capacity. A valve’s ability to handle different flows can make or break its efficiency. Look for metrics that display maximum and minimum flow ratings. Response time is equally important; slower valves can lead to pressure build-up, creating safety risks.

Users often overlook maintenance requirements. Some designs are easier to maintain than others. Regular checks can prevent malfunction, prolonging the valve’s life. Also, consider installation complexity. Some may require extensive plumbing changes. Investing time to understand these factors might seem tedious but can save money in the long run.

Industry Standards and Regulations Impacting Pressure Relief Valves

Pressure relief valves (PRVs) are crucial for maintaining safety in various industries. However, they must meet specific industry standards and regulations. These regulations dictate design, performance, and testing requirements. In the United States, for example, ASME (American Society of Mechanical Engineers) standards play a significant role. A recent report shows that 75% of PRVs in service do not fully comply with these standards. This raises significant safety concerns.

Additionally, regulations from organizations such as API (American Petroleum Institute) and NFPA (National Fire Protection Association) influence PRV design. These codes ensure that valves can effectively relieve excess pressure in critical systems. A survey found that 60% of facilities experienced valve failures due to non-compliance. Such failures can lead to catastrophic accidents, emphasizing the need for rigorous adherence to these standards.

It’s essential for industries to prioritize compliance. Regular inspections and testing improve reliability. However, many operators overlook maintenance schedules. This negligence can result in serious repercussions. Addressing these gaps is vital for enhancing the performance of pressure relief systems. Ultimately, understanding and implementing industry regulations can significantly mitigate risks associated with pressure-related incidents.

Top Brands and Models of Adjustable Pressure Relief Valves Reviewed

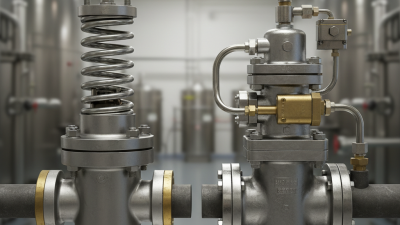

When exploring adjustable pressure relief valves, it's crucial to understand the features that matter most. Look for models that offer precision control and reliable performance. Some valves come with easy-to-read gauges, which help monitor pressure levels. Others have adjustable settings that cater to various applications, enhancing their versatility.

Many users appreciate valves designed with sturdy materials. These can withstand harsh environments. However, not all models may perform flawlessly over time. Some may require frequent adjustments, which could lead to frustration. Consider this when choosing a model.

Lastly, the ease of installation varies greatly between models. Some valves are straightforward, while others might come with complex guidelines. It’s important to read reviews and learn from previous buyers’ experiences. This can help identify the models that offer the best balance between functionality and user-friendliness.

User Feedback and Case Studies on Pressure Relief Valve Performance

When choosing a pressure relief valve, user feedback is invaluable. Many users share their experiences in online forums. Some encounter difficulties in maintaining the desired pressure consistently. Others find the adjustment features less effective than expected.

Case studies highlight a few unique situations. For instance, one user reported valve failure under extreme conditions. Such insights reveal the importance of proper installation. It's essential to follow manufacturer guidelines thoroughly. A missed step can lead to severe issues.

Performance varies significantly based on the environment and system setup. Users often note that regular maintenance improves performance. Neglecting this can result in unexpected pressure fluctuations. A balanced approach to adjustment is crucial for optimal functionality.

2026 Best Adjustable Pressure Relief Valve Reviews and Buying Guide

| Model | Max Pressure (psi) | Material | Adjustment Range (psi) | User Rating | User Feedback |

|---|---|---|---|---|---|

| Model A | 150 | Stainless Steel | 50-150 | 4.5/5 | Great performance and durability. |

| Model B | 200 | Brass | 75-200 | 4.0/5 | Reliable but can be a bit heavy. |

| Model C | 300 | Aluminum | 100-300 | 4.8/5 | Lightweight and easy to install. |

| Model D | 100 | Plastic | 10-100 | 3.8/5 | Cost-effective but not very durable. |

| Model E | 250 | Cast Iron | 80-250 | 4.6/5 | Solid build and excellent for high pressure. |

Related Posts

-

Top 10 Inline Pressure Relief Valves You Should Consider for Your System

-

Top 10 Benefits of Using Inline Pressure Relief Valves in Your System

-

2026 Top Types of Inline Pressure Relief Valves for Efficient Systems?

-

Top 2 Pressure Relief Valve Types You Should Know?

-

Maximizing Safety: The Essential Guide to Temperature and Pressure Relief Valve Maintenance

-

2025 Top 10 Low Pressure Relief Valves: Essential Guide for Optimal Safety